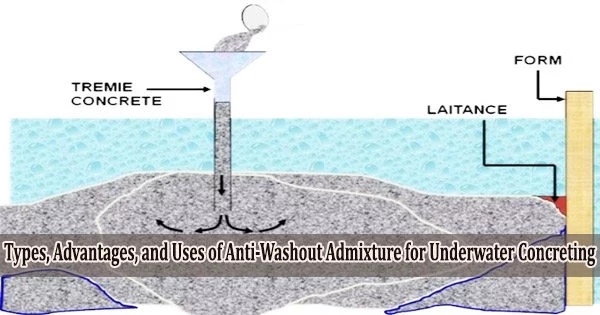

To improve the rheological characteristics of cement paste, anti-washout admixtures of concrete are created for underwater concreting. It is mostly made up of microbial polysaccharides like gum or derivatives of polysaccharides like hydroxyethyl cellulose and hydroxypropyl methyl cellulose. It has been shown that the Anti-washout additive has a significant impact on improving the cohesiveness of concrete that has been placed underwater and may washout or segregate as a result of the surrounding water.

It is also unquestionably the most widely used combination in extensive repairing and placing applications. The viscosity-improving additive, also known as the anti-washout admixture, is occasionally used to produce self-compacting concrete.

Finally, the next sections will examine the classification, practical concerns, advantages, and downsides of Anti-washout admixture.

Advantages of Anti-Washout Admixture for Underwater Concreting

In order to submerge concrete underwater without segregation and bleeding, it is added to the concrete mixture.

The rate of concrete dispersion is reduced as anti-washout additive amount is increased, which is advantageous when concreting underwater.

Disadvantages of Anti-Washout Admixture

Decreasing strength and modulus of elasticity dependent on concrete batch design, water to cement ratio, amount of additional anti-washout admixture, and its kind are the most notable drawbacks of anti-washout additive.

According to reports, the compressive strength and elastic modulus of concrete having anti-washout admixture are 75–100% and 80–100%, respectively, greater than those of concrete without the additive.

Consequently, small amount of reinforcement bars may be increased in reinforced concrete member.

Dosage of Anti-Washout Admixture for Underwater Concreting

The amount of Anti-washout admixture that must be added to the concrete mixture is determined by the amount of cementitious materials to be used, the water to cementitious materials ratio, the horizontal flow distance, the depth of the undersea placement, and the needed flow ability.

Classification of Anti-Washout Concrete Admixtures

It can be divided into the following classes:

Class-A Anti-Washout Admixtures

Water soluble synthetic and natural organic admixture which improve the viscosity of the mixing water. The ranges of this class applied are between 0.2 to 0.5% solid by mass of cement. Anti-washout admixtures containing cellulose ether, pregelatinized starches, carageenans, polyacrylamides, polyethylene oxides, alignates, carboxyvinyl polymers, and polyvinyl alcohol are examples of the Class A.

Class-B Anti-Washout Concrete Admixtures

By enhancing the attractions between cement particles, organic flocculants that may dissolve in water and be absorbed by cement particles increase viscosity. The dosage is between 0.01 and 0.10% solid by mass of cement. Examples of Class B are Styrene copolymers with carboxyl groups, synthetic polyelectrolytes, and natural gums.

Class-C Anti-Washout Concrete Admixtures

It is emulsions of different organic material that not only improve attractions between particles but also provide extremely fine particles in the cement paste. The amount of Class C anti-washout admixture that is usually added it ranges from 0.10 to 1.50% solid by mass of cement. Paraffin-wax emulsions that are unstable in the aqueous cement phase, acrylic emulsions, and aqueous clay dispersions are examples of Class C anti-washout admixture.

Class-D Anti-Washout Concrete Admixtures

These are large surface area inorganic materials which rise mixture capacity to retain water. The dosage range employed is 1-25% solid by mass of cement. Examples include bentonites, pyrogenic silicas, silica fume, milled asbestos, and other fibrous materials.

Class-E Anti-Washout Concrete Admixtures

It is inorganic materials which provide extra fine particles to the mortar pastes. The mount of the Class E that is added is between 1 to 25% solid by mass of cement. Fly ash, hydrated lime, kaolin, diatomaceous earth, other raw or calcined pozzolanic materials, and various rock dusts are examples of Class E Anti-washout admixture.

Principal Considerations for Anti-Washout Concrete Admixtures

When anti-washout additive is added to concrete mixture, there are a number of practical issues that must be taken into account. The amount of concrete mixture that must be handled and the mixer’s capacity may be the most important factors to take into account. This is due to the anti-washout additive significantly increasing the viscosity of fresh concrete, which raises the load of fresh concrete by 25 to 50%.

To reduce the water demand of concrete mixture, which is enhanced by the addition of anti-washout admixture, and so retain flow ability, high range water lowering admixture is frequently applied in combination with anti-washout admixture. Because the high range water reducing admixture lengthens the setting time, it is important to take into account the types and dosages of high range water reducing admixtures.

Another factor that must be taken into account is the pump’s capacity. On the one hand, if problems are discovered within the pressure transmission tube during the pumping pressure period, high dispersion resistance blockage may develop in pump lines. However, the pressure transmission resistance is enhanced by 2 to 4 times more than with traditional concrete due to the high viscosity of the concrete mixture.