The 2D semiconductor materials of the upcoming generation do not like what they see in the mirror. When the material is put on single-crystal substrates like sapphire, current synthesizing techniques to create single-layer nanosheets of semiconducting material for atomically thin electronics experience an odd “mirror twin” flaw.

The atom arrangements on each side of the mirror-like grain boundaries of the synthesized nanosheet are arranged in direct opposition to one another.

This is a problem, according to researchers from the Penn State’s Two-Dimensional Crystal Consortium-Materials Innovation Platform (2DCC-MIP) and their collaborators. When electrons encounter a boundary, they scatter, which lowers the efficiency of electronics like transistors.

According to the experts, this is a hurdle for the development of next-generation electronics for uses in the Internet of Things and artificial intelligence. But now, the research team may have come up with a solution to correct this defect. They have published their work in Nature Nanotechnology.

According to lead author Joan Redwing, director of 2DCC-MIP, this study could have a significant impact on semiconductor research by enabling other researchers to reduce mirror twin defects, especially given the field’s increased attention and funding from the CHIPS and Science Act approved last year. The legislation’s authorization increased funding and other resources to boost America’s efforts to onshore the production and development of semiconductor technology.

According to Redwing, a highly efficient, atomically thin semiconductor to regulate and modify electrical current flow might be made from a single-layer sheet of tungsten diselenide that is only three atoms thick.

The researchers create the nanosheet using a process known as metal organic chemical vapor deposition (MOCVD), which is used to produce incredibly thin single crystal layers onto a substrate, in this case a sapphire wafer.

While MOCVD is used in the synthesis of other materials, the 2DCC-MIP researchers pioneered its use for the synthesis of 2D semiconductors such as tungsten diselenide, Redwing said.

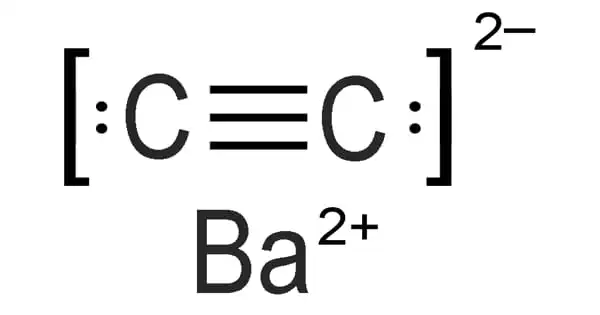

The tungsten metal is sandwiched between non-metal selenide atoms in tungsten diselenide, a transition metal dichalcogenide that is three atoms thick and has ideal semiconducting characteristics for modern electronics.

“To achieve single-layer sheets with a high degree of crystalline perfection, we used sapphire wafers as a template to align the tungsten diselenide crystals as they deposit by MOCVD on the wafer surface,” said Redwing, who is also a distinguished professor of materials science and engineering and of electrical engineering at Penn State. “However, the tungsten diselenide crystals can align in opposite directions on the sapphire substrate. As the oppositely oriented crystals grow larger in size, they ultimately meet up with one another on the sapphire surface to form the mirror twin boundary.”

We found that it was possible to get the majority of the crystals to attach at either the top or the bottom edge of the steps. This would provide a way to significantly reduce the number of mirror twin boundaries in the layers.

Joan Redwing

The researchers used “steps” on the sapphire surface to their advantage in order to overcome this problem and align the majority of the tungsten diselenide crystals with the sapphire crystals.

The sapphire single crystal that makes up the wafer is extremely flawless in terms of physics, but it is not atomically flat. There are level regions between each step and steps that are only an atom or two tall.

Here, Redwing said, the researchers found the suspected source of the mirror defect.

The tungsten diselenide crystals tended to attach, although not always, at the step on the sapphire crystal surface. When linked to the steps, the crystal alignment tended to be uniformly in one direction.

“If the crystals can all be aligned in the same direction, then mirror twin defects in the layer will be reduced or even eliminated,” Redwing said.

The researchers found that by controlling the MOCVD process conditions, most of the crystals could be made to attach to the sapphire at the steps. And during the experiments, they made a bonus discovery: If the crystals attach at the top of the step, they align in one crystallographic direction; if they attach at the bottom, they align in the opposite direction.

“We found that it was possible to get the majority of the crystals to attach at either the top or the bottom edge of the steps,” Redwing said, crediting experimental work performed by Haoyue Zhu, postdoctoral scholar, and Tanushree Choudhury, assistant research professor, in 2DCC-MIP. “This would provide a way to significantly reduce the number of mirror twin boundaries in the layers.”

Nadire Nayir, a postdoctoral scholar mentored by Distinguished University Professor Adri van Duin, led researchers in the 2DCC-MIP Theory/Simulation facility to develop a theoretical model of the atomic structure of sapphire surface to explain why the tungsten diselenide attached to the top or bottom edge of the steps.

They postulated that the crystals would adhere to the bottom edge of the steps if selenium atoms covered the sapphire’s surface; otherwise, they would attach to the top edge of the steps if the sapphire was only partially covered.

To confirm this theory, the Penn State 2DCC-MIP researchers worked with Krystal York, a graduate student in the research group of Steven Durbin, professor of electrical and computer engineering at Western Michigan University. She contributed to the study as part of the 2DCC-MIP Resident Scholar Visitor Program.

York learned how to grow tungsten diselenide thin films via MOCVD while using 2DCC-MIP facilities for her doctoral thesis research. Her experiments helped confirm that the method worked.

“While carrying out these experiments, Krystal observed that the direction of tungsten diselenide domains on sapphire switched when she varied the pressure in the MOCVD reactor,” Redwing said. “This experimental observation provided verification of the theoretical model that was developed to explain the attachment location of tungsten diselenide crystals on steps on the sapphire wafer.”

Wafer-scale tungsten diselenide samples on sapphire produced using this novel MOCVD process are available to researchers outside of Penn State via the 2DCC-MIP user program.

“Applications such as artificial intelligence and the Internet of Things will require further performance improvements as well as ways to reduce the energy consumption of electronics,” Redwing said. “High-quality 2D semiconductors based on tungsten diselenide and related materials are important materials that will play a role in next generation electronics.”