Aalto University researchers have found a novel technique to use biowaste as a thermal and acoustic insulator.

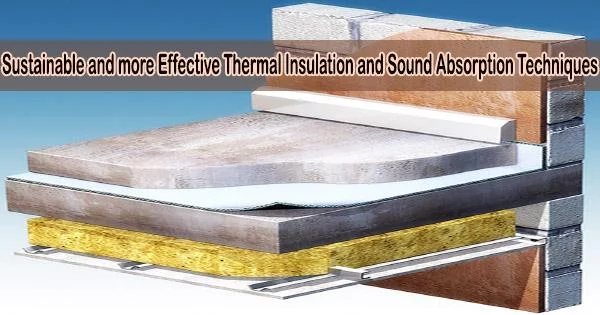

To effectively combat noise pollution, a significant environmental and health issue, sound absorption materials must be used. The present sound-absorbing materials frequently produce waste problems at the end of their useful lives and may be environmentally detrimental.

Pectin, a polysaccharide that can be recovered from biowastes like fruit peels, was discovered by the researchers to be capable of being transformed into a freeze-dried, highly porous substance. They can be more effective at absorbing sound than commercially available materials like glass wool and other porous materials of comparable thickness.

The research was published in the Chemical Engineering Journal.

“The porous material prepared in this work demonstrate the great potential of freeze-casted bio-based sound absorption materials to be employed as an alternative material in industrialization and construction, where environmental-friendly materials are needed. They also display low thermal conductivity and excellent thermal insulation performance,” says Professor Jaana Vapaavuori from the School of Chemical Engineering.

The small pores on the walls of the bigger walls constituted a hierarchically porous material. This particular structure may improve the material’s tortuosity, or the path that sound takes inside the substance, which would further increase sound absorption, particularly at high frequencies.

This particular structure has not previously been mentioned in relation to bio-based acoustic absorbers.

“The material has a structural hierarchy consisting of pores of different dimensions and scales. This type of structuring allowed optimizing the sound absorption performance of the material the sound can penetrate deep into material, and thus, the viscous and thermal losses in the materials are enhanced,” says Professor Tapio Lokki from the School of Electrical Engineering.

Collaboration with a local store

The researchers are able to utilize waste streams that are currently being produced, which is the obvious advantage of extracting pectin from biowaste. The research team, directed by professors Lokki and Vapaavuori, is exploring for ways to use locally produced biowaste in their studies.

“Now the work continues into an exploration of how raw material could be sourced directly from a local biowaste. We have been negotiating with a local K-market for waste exchange and a chance to collect the orange peels from their juice pressing machine,” says Vapaavuori.