In order to apply a universal superlattice film to mechanical parts and achieve long-term macroscale superlubricity with self-rejuvenation, a research team led by Prof. Wang Liping at the Ningbo Institute of Materials Technology and Engineering (NIMTE) of the Chinese Academy of Sciences (CAS) and Prof. Li Qunyang at Tsinghua University developed the universal superlattice film. The research was released in the journal Cell Reports Physical Science.

Friction occurs frequently in nature and is thought to use up around one-third of all energy in the world. It can have a substantial influence on human life to reduce friction to extremely low levels or even to a superlubricious condition with a friction coefficient of 10-3. However, creating strong macroscale superlubricity between dry solid surfaces remains difficult; in earlier investigations, lamellar materials have mostly been used to produce this phenomenon at nanoscale scales.

To overcome this difficulty, the researchers created a universal molybdenum disulfide (MoS2)/ceramic superlattice architecture, which after a brief running-in phase in air, permits long-term (near to 300,000 sliding cycles) macroscale superlubricity in a moderate vacuum.

The bilayer unit’s ability to precisely adjust each sublayer’s thickness gives the film its exceptional superlubricity (0.006 friction coefficient). More intriguingly, when the film unintentionally comes into contact with air, the lubricating ability can be revived.

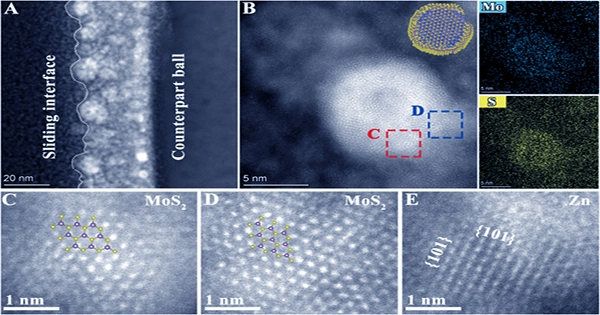

The super lubricious interface is thought to be the consequence of sliding metal oxide (MeOx) nanoparticles wrapped in MoS2 moving between highly ordered MoS2 flakes. This process divides the macroscopic contact area into multiple incommensurate nanocontact zones, resulting in robust superlubricity.

The specific wear rate of the superlattice layer was decreased to an extremely low level on the order of 10-9 mm3 N-1 m-1 thanks to the strong superlubricity.

These discoveries provide a fresh method for creating adaptable solid lubricants, which might lead to ground-breaking ground and space applications. However, creating strong macroscale superlubricity between dry solid surfaces remains difficult; in earlier investigations, lamellar materials have mostly been used to produce this phenomenon at nanoscale scales.

To overcome this difficulty, the researchers created a universal molybdenum disulfide (MoS2)/ceramic superlattice architecture, which after a brief running-in phase in air, permits long-term (near to 300,000 sliding cycles) macroscale superlubricity in a moderate vacuum.

The bilayer unit’s ability to precisely adjust each sublayer’s thickness gives the film its exceptional superlubricity (0.006 friction coefficient). More intriguingly, when the film unintentionally comes into contact with air, the lubricating ability can be revived.