Concrete is one of the most widely used construction materials throughout the world. Many desirable properties such as high compressive strength, excellent durability and fire resistance contributed toward its wide range of applicability.

The most advantageous and unique feature of concrete is that it can be produced using locally available ingredients as aggregates. Therefore in counties where steel is not readily available as in Bangladesh, concrete is the most used constriction material.

However the advantage of using local materials as concrete ingredients has its own demerits as well .Because of the variation in properties of locally available aggregates , the properties of concrete may vary widely.

Although plant mixed concrete is gaining population day by day. And in many big projects concrete is still produced and lays in the field. This calls for the proper selection of the concrete ingredients and their relative proportion in a concrete mix the proportion of ingredients in a concrete mix to achieve a target property is known as the concrete mix design.

Different methods are available to design a normal concrete mix for a given strength under various weather and workability condition. Among the various methods in use . he method proposed by the American Concrete Institute (ACI) is probably the most popular one.

However some recent experiences and subsequent studies made at the Bangladesh University of Engineering and Technology (BUET) have revealed that the ACI method of mix design fails to predict the relative ratio of fine and coarse aggregate for some case. In such cases the designed mixes fail to attain design strength. A parametric study has been carried out by the authors to look into the matter. This paper deals with the outcome of the parametric stud.

Objective of the study:

The main objectives of the study are given blow

- To obtain sieve analysis of fine aggregate.

- To obtain sieve analysis of coarse aggregate.

- To obtain specific gravity and absorption capacity of the fine aggregate.

- To obtain specific gravity and absorption capacity of the coarse aggregate.

- To obtain Unit Weight of Coarse aggregate.

- To obtain Unit weight and voids in aggregate.

- To obtain Flakiness Index Test.

Scope and limitation of the study:

We have been collected materials from construction project in Dhaka city we have been aggregate test sieve analysis of fine aggregate and coarse aggregate Specific gravity and absorption capacity of the fine aggregate , Specific gravity and absorption capacity of the coarse aggregate , Unit weight and voids in aggregate in Stamford University laboratory.

In within short time we have tried our best to complete the work. It is a problem to carrying materials. if we made more cylinder test then we obtain variation result in mix design.

Organization of the thesis:

The thesis represents literature review, methodology test procedure conclusion and reference of book and websites and laboratory test used for the study .

This includes background, objective, scopes and limitation of the study.

Include literature review covering introduction , definition of concrete , Type of concrete materials of concrete Cement Aggregates , Water , Chemical Admixture , Properties of concrete Water cement ratio and its effects on concrete properties Aggregate variation in Bangladesh ,

Includes the methodology and test procedure covering introduction , The working methodology of our study , Steps of ACI design method , test of aggregate , test of concrete , Quality test, test procedure of aggregate .

Concrete

Concrete is an artificial stone manufactured from a mixture of binding materials and inert materials with water.

Concrete = Binding materials + Inert materials + Water.

Concrete is considered as a chemically combined mass where the inert material acts as a filler and the binding material acts as a binder. The most important binding material is cement and lime. The inert materials used in concrete are termed as aggregates. The aggregates are of two types namely, (1) Fine aggregate and (2) Coarse aggregate. (Ref.l)

Fine aggregate

Sand and Surki are commonly used as fine aggregate in Bangladesh. Stone screenings, burnt clays, cinders and fly-ash are sometimes used as a substitute for

Sand in making concrete. The fine aggregate should not be larger than 3/16 inch (4.75mm) in diameter.

Coarse aggregate

Brick khoa (broken bricks), broken stones, gravels, Pebbles, clinkers, cinders etc. of the size of 3/16 to 2 inch are commonly used as coarse aggregate in Bangladesh. It may be remembered that 3/16 inch is the dividing line between fine and coarse aggregates.

Functions of Aggregates in Concrete

The aggregate give volume to the concrete around the surface of which the binding material adheres in the form of a thin film. In theory the voids in the coarse aggregate is filled up with fine aggregate and again the voids in the fine aggregate is filled up with the binding materials. Finally, the binding materials as the name i the individual units of aggregates into a solid mass with the help of water.

Qualities of Aggregates

Since at least three quarters of the volume of concrete is occupied by aggregate. It is not surprising that its quality is of considerable importance. Not only the aggregate limit the strength of the concrete, as weak aggregates cannot produce a strong ‘concrete, but also the properties of aggregates greatly affect the durability and structural performance of the concrete.

Aggregate was though, originally viewed as an inert material dispersed throughout the cement paste largely for economic reason, yet it is possible, however, to take an opposite view and to look on aggregate as a building material connected into a cohesive whole by means of cement paste, in a manner similar to masonry constructions. In fact aggregates are not truly inert and their physical, chemical and sometimes thermal properties influence the structural performance of a concrete.

Aggregates are cheaper than cement and it is therefore, economical to put into the mix as much as of the former and as little of the latter. But economy is not the only reason for using aggregate; it confers considerable technical advantage on concrete, which has a higher volume stability and better durability than the cement paste alone. The coarse aggregate should be clean, strong, durable and well grades and should be free from impurities and deleterious materials, such as salts, coal residue, etc.

Classification of Concrete

There are mainly two types of concrete, Namely.

- Lime concrete and

- Cement concrete.

Lime Concrete = Lime + Surki + Khoa+Water

Cement concrete = Cement + Sand+Khoa + Water

Lime Concrete

Lime concrete consists of lime surki and khoa or stones in the proportion 1:2:5 unless otherwise specified. The khoa or stones should be soaked thoroughly in water before mixing. The lime and surki in required proportion are to be first mixed dry by volume on a clean watertight platform till the color is uniform. The requisite quantity of thoroughly soaked khoa or stones is then added and the whole again mixed very thoroughly.

Water is then added gradually and mixing is continued till a workable mixture is obtained. Concrete should be mixed in such a quantity that it can be utilized during the day it is mixed and the concrete which has been left overnight should not be used. The concrete thus mixed should be laid evenly in the position in which it is desired to be used. The common practice of throwing concrete in the desired position by the workers should be avoided. Concrete is to be laid in layers not exceeding 3 inch in thickness. Each layer is to be thoroughly compacted before the next layer is laid. Concrete is to be kept well wetted while setting and at least 7 days after the final layer is completed. Lime concrete is used mainly in foundation and in terrace roofing. (Ref. 1)

Cement concrete

Cement concrete is widely used in all important engineering constructions. It consists of cement, sand and brick khoa or stones of required size in the proportion 1:2:4 or 1:3:6 unless otherwise specified. The ingredients are measured dry separately by volume according to required proportion. In measuring cement, generally 90 Ibs will be taken as 1 cu ft. and hence 1 bag of cement (112 Ibs) equals 1.25 cu.ft. The khoa or stones are soaked thoroughly in water before use. The fine and coarse aggregates are mixed dry first on a clean watertight platform. The cement is then added and the whole is mixed thoroughly. When the coarse aggregate has been soaks thoroughly the approximate quantity of water is 4.5 gallons for one cu.ft of cement in a concrete of 1:2:4. The quantity of water should be such that the mixture would give a good workability. The concrete is to be prepared in small quantities which can be used within 45 minutes and any unused concrete after that time should not be used. In foundation works, the concrete is to be rammed properly till the water appears of top and on khoa or stone is left uncovered by mortar. In reinforced concrete work, the concrete is to be poke very thoroughly with steel rods of recommended size to get rid of voids and to ensure a good bond between concrete and the reinforcing steel. Sometimes a mechanical vibrator is used to minimize voids. As soon as the concrete has set the surface should be sprayed with water. The process of curing is to be applied for 28 days to attain its proper strength.

Mixing concrete by band does not generally produce a good concrete. Where large quantity of concrete is required and also a very good quality concrete is desired, the mixing is done in a mechanical mixer. (Ref. 1

Advantage of concrete over other materials of construction

Followings are the advantage of concrete over other materials of construction:

• Concrete is free from defects and flaws which natural stones are associated.

• It can be manufactured to desired strength and durability with economy.

• It can be cast to any desired shape.

• Maintenance cost of concrete structures is almost negligible.

• Concrete does not deteriorate appreciably with age.

Segregation

Segregation can be defined as separation of the constituents of a heterogeneous mixture so that their distribution is no longer uniform. In case of concrete it is the difference in the size of particles and in the specific gravity of the mix constituents” that are the primary caused of segregation, but its extent can be controlled by the of suitable grading and water-cement ratio and by care in handling transporting placing of concrete. In concrete, there are two forms of segregation. First the coarse particles tend to travel further along a slope or settle more than finer particles. The second form of segregation occurring particularly in wet mixes is manifested by the separation of grout from the mix. With some grading where a lean mix is used, the first type of segregation may occur; if the mix is too dry; addition of water would improve the cohesion of the mix but when the mix becomes too wet, second type of segregation would take place

Bleeding

Bleeding (known also as water gain) is a form of segregation in which some of the water in the concrete mix tends to rise to the surface of freshly placed concretes. This is caused by the inability of the solid constituents of the mix to hold all of the mixing water when they settle downwards. Bleeding is a special case of sedimentation. It can be expressed quantitatively as the total settlement per unit height of concrete. As of bleeding result of bleeding the top of concrete becomes too wet and if the water is trapped by super imposed concrete a porous, weak and non-durable concrete will produced.

If the bleeding water is remixed during finishing of the top surface, a weak wearing Suffice will be found. This can be avoided by delaying the finishing operation until the Weeding water has evaporated. On the other hand, if evaporation of water from the jar face of the concrete is faster than the bleeding rate, plastic shrinkage cracking may result.

Laitance

Laitance is the formation of a crust of squeezed out mortar on the surface of concrete. This is due to bleeding and bad workmanship. This produces a bad or weak concrete. For preparing watertight concrete, Segregation, Bleeding and Laitance should be very carefully avoided.

Hardening

Process of gaining strength by the mass of cement concrete is known as hardening.

Tri-Calcium Silicate hydrate first and responsible for most of early strength of concrete. Strength acquired during first 7 days is mostly due to hydration of Di- Calcium Silicate…starts contributing strength after 7 days to a year.2.6.3 Setting Process of loosing plasticity is known as setting. Tri –Calcium Aluminates responsible for early setting of cement does not contribute any strength.

Tetra Calcium Alumino Ferrite….does not play any significant roll in setting and hardening properties. For delaying setting for 30 to 40 minutes add 1-3% gypsum powder in cement. Initial setting of cement,45 min to 8-10 hours Final setting time,5 to 20 hours. Progressive hardening time ,24 hours to a year. Within 30 days 80-90% strength gain.

Admixtures

In addition to the main components of concretes, admixtures are often used to improve concrete performance. There are admixtures to accelerate or retard setting and hardening, to improve workability, to increase strength, to improve durability, to decrease permeability, and to impart other properties of high strength concrete. The beneficial effects of particular admixtures are well established. Chemical admixtures should meet the requirements of ASTMC 494,“ Standard Specification for Chemical admixtures for concrete.” (Ref.3)

Workability of Concrete

The strength of concrete of given mix proportion is very seriously affected by the degree of its compaction ; it is therefore, vital that the consistency the mix be such that the concrete can be transported placed and finished sufficiently easily and without aggregation. A concrete satisfying these condition is said to be workable but to say uerely that workability determines the case of transportation, placement and finishing sand the resistance of concrete to segregation is too loose a description of this vital property of concrete workability can be best defined as a physical property which is the amount of useful external and internal works necessary to produce of compaction of concrete.

Another term used to describe the state or fresh concrete is consistency. In a simple language the word consistency refers to the firmness of a form of a substance or to the case with which it will flow. In case of concrete, consistency is sometimes taken to mean the degree of witness within limits. Wet concrete are more workable than dry concrete, concretes of the same consistency may vary in workability.

Factors affecting workability

The main factor is the water content of the mix, expressed in pounds per cube yard of concrete. It

is convenient, though approximate, to assume that for a given type and grading of aggregates and workability of concrete. The water content is independent of the aggregate cement ratio. On the basis of this assumption the mix proportions of concretes of different richness can be estimated and the following Table 2.1 gives typical values of water content for different slumps and maximum size of the aggregates.

Workability is also governed by the maximum size of the aggregates their grading, shape and texture. Grading and water/cement ratio have to be considered together as a grading producing most workable concrete for one particular value of water/cement ratio may not be the best for another value of the ratio. In particular, the higher the water/cement ratio the finer the grading required for the highest workability. In actual fact, for a given value of water/cement ratio, there is only one value of the coarse/fine aggregates ratio that gives the highest workability.

Air entrainment also increases workability. In general terms, entrainment of 5 percent air increases the compacting factor of concrete by about 0.03 to 0.07 and slump by 1A to 2 inch but actual values vary with properties of the mix. Air entrainment is also effective in improving the workability of the rather harsh mixes made with light weight aggregates.

The reason for the improvement of workability by the entrained air is probably that air bubbles act as a fine aggregate of very low surface friction and considerable elasticity. f It is also claimed that the air entrainment reduces both segregation and bleeding.

Approximate Water Content for different Slumps and Maximum sizes of Aggregates

| Maximum | Water content in Ib per cu yd. of concrete | |||||

| Size of aggregates inch | 1-2 inch slump | 3-4 inch slump | 6-7 inch slump | |||

|

| Rounded Agg. | Angular Agg. | Rounded Agg. | Angular Agg. | Rounded Agg. | Angular Agg. |

| 3/8 | 320 | 360 | 340 | 380 | 390 | 430 |

| 3/4 | 290 | 330 | 320 | 350 | 350 | 380 |

| r/2 | 270 | 290 | 290 | 320 | 320 | 350 |

| 2 | 250 | 280 | 280 | 300 | 300 | 330 |

| 3 | 230 | 260 | 260 | 280 | 270 | 310 |

Measurement of Workability

Unfortunately no test is known that will measure directly the workability, numerous attempts have been made, however, to correlate workability with some easily measurable parameter. But none of these is fully satisfactory although they may provide useful information within a range of variation in workability. Water content for different size of aggregates is followed as per Table 2.1 as shown above.

Factors controlling properties of Concrete

The properties (Strength, durability, impermeability and workability) of concrete depend upon the following parameters (factors):

- Grading of the aggregates.

- Moisture content of the aggregates.

- Water/cement ratio.

- Proportioning of the various ingredients of concrete.

- Method of mixing.

- Placing and compaction of concrete.

- Curing of concrete.

Water/Cement ratio

In engineering practices, the strength of concrete at a given age and cured at a prescribed temperature in assumed to depend primarily of two factors:

- The water/cement ratio and

- The degree of compaction.

The proportion between the amount of water and cement used in a concrete mix is termed as the water cement ratio.

The water in the concrete does primarily the three functions:

1. To wet the surface of the aggregate,

2. To impart workability and

3. To combine chemically with cement.

When concrete is fully compacted, its strength is taken to be inversely proportional to water-cement ratio. It may be recalled that the water-cement ratio determines the porosity of the hardened cement paste at any stage of hydration.

Experiments have shown that the quality of water in a mix determines its strength and there is a water/cement ratio which gives the maximum strength to the concrete. It will be found that there is a certain percentage of water below which the water will not be sufficient to hydrate the cement. The use of less water than that required will not give workability and will produce porous and weak concrete. On the other hand if more water is used than that actually required, the concrete will be weak.

Flakiness Index

This test is based on the classification of aggregate particles as flaky when they have a thickness (smallest dimension) of less than 0.6 of their nominal size, this size being taken as the mean of the limiting sieve apertures used for determining the sieve fraction in which the particle occurs. The flakiness index often aggregate sample is found by separating flaky particles and expressing their mass as a percentage of the mass of the sample tested. The test is not applicable to materials passing a 6.3mm B.S Test Sieve and retains a 63 mm B.S Test Sieve.

Fundamental considerations

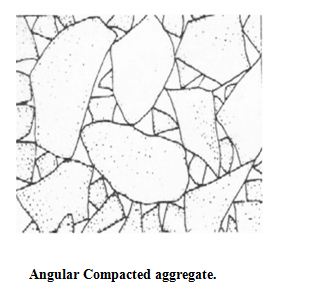

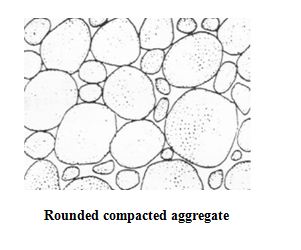

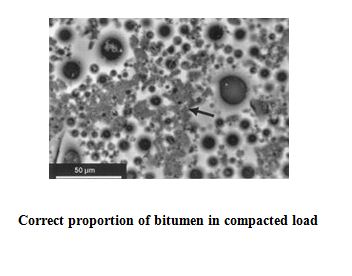

Various factors which affect mix design criteria can be clarified physically exhibiting bitumen concrete pavement having varying bitumen content and various shape of the aggregate particle. The following figure-1 to fig-4 shows such physical exhibits.

Figure-2.1 shows a frame work of aggregate particle in a mix of crushed; graded aggregate which has been compacted. All the aggregate particles are in contact with one another. This frame work of aggregate particles has considerable to movement under superimposed load

Shows a frame work of rounded aggregate particles which have been compacted. This frame work has considerably less stability than that shown in fig-1. If the surface of the rounded particles is made rough to resist sliding of one over another, it can still offer certain resistance to movement. If the stone particles are smooth, the frictional resistance becomes very small and the compacted frame work of particles will have practically no resistance to movement. Rounded particle also practically have no interlocking. The sum of frictional resistance and interlocking comprises which is known as internal friction.

Shows a frame work of rounded aggregate particles which have been compacted. This frame work has considerably less stability than that shown in fig-1. If the surface of the rounded particles is made rough to resist sliding of one over another, it can still offer certain resistance to movement. If the stone particles are smooth, the frictional resistance becomes very small and the compacted frame work of particles will have practically no resistance to movement. Rounded particle also practically have no interlocking. The sum of frictional resistance and interlocking comprises which is known as internal friction.

3 gives a diagrammatic view of a properly designed bituminous pavement. In this diagram the load from wheels of the traffic is carried directly by the frame work of stones. The frame work of stone is held in position by binding action of the bitumen. The open spaces between aggregate particles are not completely field with bitumen but air voids as indicated by white small circles are left. The void space should constitute from 2% to 6% of the total volume of the pavement.

4 shows a diagrammatic view of a bitumen mix having larger amount of bitumen than required. In this condition of the frame- work, the interlocking effect of the stone particles is destroyed and individual stone particles will just be floating. This condition results in bleeding, shoving, or rutting and therefore must be voided. This greatly reduces the traffic load carrying capacity of the road. To avoid such a condition at least 2% air voids must be present in the pavement.

Bitumen content if add just sufficient to act as binder may leave high volume of air voids.

In this condition the mix will still have good resistance to movement but high volume of voids is helpful in hardening of bitumen because of weathering, and may shorten the life of the pavement. On the other hand, low bitumen content may develop brittle pavement which ravel under the action of the traffic. To avoid undue hardening of the bitumen and raveling, the maximum limit of air voids may be restricted to 6%. However, in some methods of design, this limit is restricted to 5%.The volume of air voids is, sometimes,

expressed by term percent density. This expression denotes the volume of solids. For instance a pavement with 97% density has 3% air voids.

For a specified grading and aggregate, percent density is function of the bitumen content in the mix and the degree of compaction. The pavements are normally designed at 96% to 97.5% density.

Percentage of voids in the pavement plus the percentage volume occupied by the bitumen is known as voids in the mineral aggregate (VMA). Single size aggregate has maximum value of VMA which may be as high as 35% to 40%. Poorly graded aggregate have VMA ranging from 20% to 35% while well graded have its value less than 20%. It is good to reduce the VMA to the lowest possible value, but through proper distribution of size of aggregate.

Value of VMA should not be reduced by using excessive 75 mic passing material i.e. filler. A well graded aggregate without excess use of 75 mic passing material, will normally give VMA value 15% in compacted specimen. Aggregate having value of VMA less than 10 should not be used, as such a low value can only be obtained

through excessive use of mineral fill

The amount of bitumen, required to produce a given percentage of voids in the mix is largely a function of the surface area per unit weight of aggregate, which is a function of the particle size.

This is the reason that the optimum bitumen content is larger for mixes with a small-top size aggregate than for a large top-size aggregate. Roughnc5s of the surface of the aggregate particle and the amount of bitumen it absorbs, also affect the amount of bitumen to some extent.

Generally strength of concrete can be increased by increasing cement content decreasing water/cement ratio. However, there may be a threshold value of cement content beyond which strength are met increased for a particular type of course and fine aggregate. On the other hand, to prepare a workable concrete, there should, have a limiting value of water/cement ratio. Strength of concrete with specific cement content, water/cement ratio, and the maximum size of coarse aggregate, the strength of concrete increase with decreasing the maximum size of aggregate up to a limiting value 10 mm. On the basis of the above statement. Cement content, water/cement ratio, maximum size of aggregate are taken as the parameter in the parametric study and different sample are prepared.

The working methodology of our study is as follows:

a) Selection of materials (bricks, fine aggregate, coarse aggregate, cement content,

water cement ratio, and admixture)

b) Sample preparation

c) Curing

d) Testing

e) Analysis of the test results

f) Conclusion

Test of aggregate:

Specific Gravity:

In concrete technology, specific gravity of aggregates is made use of in design calculation of concrete mixes. With the specific gravity of each constituent known, its weight can be converted into solid volume and hence a theoretical field of concrete per unit volume can be calculated. Specific gravity of aggregate is also required in calculating the compacting factor s connection with the workability measurements. Similarly, specific gravity of aggregate is squired to be considered when we deal with light weight concrete. Average specific gravity of the rocks varies from 2.6 to 2.8.

Fineness modulus:

A single factor computed from the sieve analysis is sometimes used, particularly in the US. This is the fineness modulus (FM), defined as the sum of the cumulative percentages retained on the sieves of the standard series, and divided by 100.

The standard series consists of sieves, each twice the size of the preceding one, viz; 150, 300, 60um. 1.18, 2.36, 5.00mm (ASTM No. 100, 50, 30, 16, 8, 4) and up to the largest sieve size present. The fineness modulus is calculated for the fine aggregate rather than for coarse aggregate. Typical values range from 2.3 and 3.0, a higher value indicating a coarser grading. the usefulness of the fineness modulus lies in detecting slight variations in the aggregate from the same source which could affect the workability of the fresh concrete.

Bulk Density:

The bulk density or unit weight of an aggregate gives valuable information’s regarding the shape and grading of the aggregate. Specific gravity the angular aggregates show a lower bulk density. The bulk density of aggregate is measured by filling a container of know volume in a standard manner and weighing it. The Bulk density depends on the particle size distribution and shape of fhe particles. One of the early methods of mix design makes use of this parameter bulk density proportioning of concrete mix. The higher the bulk density, the lower is the void content to be filled by sand and cement.

for determination of bulk density the aggregates are filled in the container and then they are compacted in a standard manner. The weight of the aggregate gives the bulk density calculated in kg/litter or kg/m.The specific gravity of the aggregate in saturated and surface dry condition the void ratio can also be calculated

Percentage voids =GS-Y X 100

Gs

Absorption:

The water absorption is determined by measuring the decrease in mass of a saturated and Surface-dry sample after oven drying for 24 hours. The ratio of the decrease in mass to the I mass of the dry sample, expressed as a percentage, is. termed absorption. Standard procedures are it described in BS 812.

Moisture content:

Absorption represents the water contained in the aggregate in a saturated, surface-dry condition; we can define the moisture content as the water in excess of the saturated and I surface-dry condition. The total water content of a moist aggregate is equal to the sum of absorption and moisture content. The total moisture content (percent) of the dry mass of aggregate is

Test of concrete:

Compressive strength

Compressive Strength of Concrete: Concrete mixtures can be designed to provide a wide range of mechanical and durability properties to meet the design requirements of a structure. The compressive strength of concrete is the most common performance measure used by the engineer in designing buildings and other structures. The compressive strength is measured by breaking cylindrical concrete specimens in a compression-testing machine. The compressive strength is calculated from the failure load divided by the cross-sectional area resisting the load and reported in units of pound-force per square inch (psi) in US customary units or megapascals (MPa) in SI units. Concrete compressive strength requirements can vary from 2500 psi for residential concrete to 4000 psi and higher in commercial structures. Higher strengths up to and exceeding 10000 psi and specified for certain applications.

Compressive strength determined:

Compressive strength test results are primarily used to determine that the concrete mixture as delivered meets the requirements of the specified strength, fc in the job specification.

Strength test results from cast cylinders may be used for quality control, acceptance of / concrete or for estimating the concrete strength in a structure for the purpose of scheduling construction operations such as from removal or for evaluating the adequacy of curing and A study on concrete strength with respect to aggregate variation in Mix design

Protection afforded to the structure. Cylinders tested for acceptance and quality control are and cured in accordance with procedures described for standard-cured specimen in ASTM C 31 Standard Practice for Making and Curing Concrete Test Specimens in the Field. A test result is the average of at least two standard-cured strength specimens made from the concrete sample and tested at the same age. In most cases strength requirements for concrete are at an age of 28 days. Design engineers us the specified strength fc to design structural elements. This specified strength is incorporated in the job contract documents. The concrete mixture is designed to produce an average strength, fr higher than the specified strength such that the risk of not complying with the strength specification is minimized. To comply the strength requirements of a job specification both, the following acceptance criteria apply: The average of 3 consecutive tests should equal or exceed the specified strength, fc No single strength test should fall below fc by more than 500 psi or by more than fc is more than 5000 psi.

Quality Tests

Sed and aggregate intended for use by the contractor or supplier for the project must meet Relation and quality tests as outlined in section 03055 Part 2 of the Standard Specifications Format and shall be tested and approved for acceptance prior to use.

Test Procedure of aggregate:

The name of list test of aggregate are:

- Sieve analysis of fine aggregate and coarse aggregate (Grading curve and F.M are to

be determine. - Specific gravity and absorption capacity of the fine aggregate.

Specific gravity and absorption capacity of coarse aggregate.

Unit weight and voids in aggregate.

A study on concrete strength with respect to aggregate variation in Mix design

Sieve analysis of fine aggregate and coarse aggregate (F.M are to be determine.)

Scope

This test method covers the determination of the particle size distribution of fine and coarse aggregates by sieving. A weighted sample of dry aggregate is separated through a series of progressively smaller openings for determination of particle size distribution.

Theory

The term sieve analysis is given to the simple operation of dividing a sample of aggregates Infraction each consisting of particles between specific limit. The analysis is conducted to determine the grading of materials proposed for use as aggregates or being used as aggregates. The term fineness modulus (F.M) is a ready index of coarseness or fineness of the agrial. It is an empirical factor obtained by adding the cumulative percentages of aggregates retained on each of the standard sieves and dividing this sum arbitrarily by 100.

Apparatus

Eclectic balance

Sieve (ASTM Standard)

Materials:

Fine aggregate =1614.10gm (Exp.01)

Fine aggregate =1599.80gm (Exp.02)

Coarse aggregate=2850.60gm (Exp.01)

Coarse aggregate=2789.55gm (Exp.02)

Procedure

Dry sample to constant weight at a temperature 110±5°C

Select suitable sieve sizes to obtain the required information as specified.

Nest the sieves in order of decreasing size of opening from the top to bottom. Place

the pan below the bottom sieve. Place the sample on the top sieve. Place lid over top sieve.

Agitate the sieves by hand or by mechanical apparatus for a sufficient period such that not more than 1% by weight of the residue on any individual sieve will pass that sieve during 1 min. of additional hand sieving. Ten minutes of original sieving will usually accomplish these criteria.

Determine the weight of material retained on each sieve. The total retained weights should closely match the original weight of the sample (within 0.3%)

Specific gravity and absorption capacity of the fine aggregate.

The method C 128 covers the determination of bulk, SSD specific gravity and apparent

Specificgravity and absorption of fine aggregate.

The bulk and apparent specific gravity are defined according to ASTM El2, while absorption defines in ASTM C125.

Apparatus:

- Electric balance

- Pycnometer

- Electric oven

- Pan

Materials

A study on concrete strength with respect to aggregate variation is Mix design

- Sand

- Water

- Temperature: Room temperatures not consider.

Procedure:

Obtain approximately 1 kg of the water soaked material by the following process. Decant excess water from the pan in which the fine aggregate has been soaking, being careful to avoid loss of fines.

- Spread sample on a flat nonabsorbent surface exposed to a gently moving current of warm air, stirring frequently to ensure uniform drying.

- Follow the cone- test for surface moisture, subsequently described; this cone test

determines whether or not surface moisture is present on the fine aggregate particles.

The first trial of the cone test must be made with some surface water present in the

sample.

- Continue drying with constant stirring of the sample and cone tests at frequent

intervals until the cone test indicates that the fine aggregate has reached a saturated

surface dry condition. - Cone test place mold, large side down, on a dry nonabsorbent surface. Place a portion

of the partially dried sample loosely in the mold by filling it to overflowing. Lightly

tamp the sample into the mold with 25 light drops of the tamper. The tamper should

free fall under gravity during each drop. Distribute the 25 drops over the surface of

the sample.

• Remove loose and from around the outside base and lift the mold vertically. If surface

moisture is still present, the sand cone will retain its molded shape. When the molded

shape slightly slumps, a saturated surface dry condition has been reached.

Specific gravity and absorption capacity of the coarse aggregate.

Scope:

This test method covers the determination of specific gravity and absorption of coarse aggregate. The specific gravity may be expressed as bulk specific gravity, bulk specific gravity (SSD) or apparent specific gravity. The bulk specific gravity (SSD) and absorption are based on aggregate after 24 hr soaking in water.

Specific Gravity is the ratio of the weight of a given volume of aggregate to the weight of an equal volume of water.

Specific Gravity is important for several reasons. In Portland Cement Concrete the specific gravity of the aggregate is employed in calculating the percentage of voids and the solid volume of aggregates in computations of yield. The absorption is important in determining the net water-cement ratio in the concrete mix. Knowing the specific gravity of aggregates is also critical to the construction of water filtration systems, slope stabilization projects, railway bedding and many other applications.

Apparatus:

- Scale or Balance

- Water displacement bucket

- Graduated measuring jar

- Sieves, No. 4

Materials:

- Coarse aggregate

- Stone

- Water

.27Dry sieve the sample through a No. 4(4.75mm) sieve and discard any material that

passes the sieve amount of material passes the No.;4(4.75mm) sieve, need to use a

No. 8(1.18mm) sieve instead of the No. 4(4.75mm), or need to perform a specific

gravity on minus No. 4(4.75mm) material. Wash the aggregate retained on the No.

4(4.75mm) sieve.

- Completely immerse the aggregate in water in a container or deep tray at room

temperature for a period of 24 hrs. - Remove the sample from the container and drain any excess water from the aggregate.

- Using an absorbent cloth (an absorbent towel usually works best), roll the aggregate

until the surface water has been removed. Rolling up the aggregate into the towel and

then shaking and rolling the aggregate from side to side is usually effective in

reducing the sample to an SSD condition.

Weight SSD sample to nearest 1.0 gm to record this as SSD weight (B) gm.

Fill the water-displacement-bucket with water until water flows freely through thenozzle of the bucket. Mold for some time until water flowing stops.

Place an empty graduated measuring cylinder under the mouth of the nozzle,

the place entire sample in container very carefully and gently so that no water sprinkles in dropping the aggregate into water. Ensure that the overflow is working properly to compensate for the water displaced by the sample. When water flowing stops, record the weight of the displace water to the nearest 1.0 gm as the weight of displaced water (W) gm.

Remove the total test sample from the water-displacement-bucket. Dry the sample in a pan to a constant weight in an oven regulated at 230 ± 90F (110±50C). Cool in air at room temperature for 1 to 3 hrs. or until the aggregate can be comfortably handled. Record weight to nearest 1.0 gm as oven dry weight (A) gm.

Unit weight, voids and Moisture content in aggregate.

Scope:

Test method C29 covers the determination of unit weight in a compacted or loose condition and calculated voids in fine, or coarse aggregates based on the same determination. This test method is often used to determine unit weight values that are necessary for use for many methods of selection proportions for concrete mixtures.

Apparatus:

Scale or balance

- Tamping Rod -a round, straight steel rod, 5/8 in. (15.6mm) in diameter and

approximately 224 in. (600 mm) in length, having one end rounded to a hemispherical

tip of the same diameter as the rod. - Measure -a cylindrical metal watertight measure (having 150 mm dia. and 300 mm in height.

- scoop

- Straightedge

Materials:

- Coarse aggregate -Oven dried at 110 C, and then cooled to room temperature.

- Fine aggregate -Oven dried at 110°C, and then cooled 1o room temperature.

Procedure:

Measure Calibration:

Determine weight of dry measure.

Fill the measure completely full with water and determine the weight of measure plus

water.

Calculate the weight of water by taking the difference between the measurements

obtained in ( 1 ) and (2) above.

Calculate the volume of the container, V=Ww/yw, where Ww is the weight of water used

o fill the container and yw is the unit weight of water. The computed volume should be close

to the nominal value state in apparatus section.

Loose Unit weight (shoveling procedure):

1 Fill the measure to overflowing by means of a scoop, discharging the aggregate from a height not to exceed 2 in. (50 mm) above the top of the measure.

2. Level the surface of the aggregate with a straightedge.

3. Compact I nir w eight (rodding procedure):

Fill the measure one-third full and level the surface with the fingers.

4 Rod the layer of aggregate with 25 strokes of the tamping rod evenly distributed over the

5.Add additional aggregate to the measure to the two-thirds full level, level with the fingers, and rod again with 25 strokes of the tamping rod.

6. Finally add additional aggregate to overflowing and rod again using 25 strokes of the [teping rod. ”Level the surface of the aggregate with a straightedge.

7. Dciermine the weight of the measure plus content, and the weight of the measure alone,

8. Brding values to the nearest 0. 1 Ib (0.05 kg),

It is very necessary to test of aggregate to get good result for Mix design. We discuss about this chapter on aggregate test of sieve analysis of fine aggregate and coarse aggregate, Specific gravity and absorption capacity of the fine aggregate, Specific gravity and absorption capacity of coarse aggregate, Unit weight and voids in Coarse aggregate

Test Performed:

The name of list test of aggregate are:

Sieve analysis of fine aggregate and coarse aggregate (Grading curve and F.M are to

be determine.

- Specific gravity and absorption capacity of the fine aggregate.

- Specific gravity and absorption capacity of coarse aggregate.

- Unit weight and voids in aggregate.

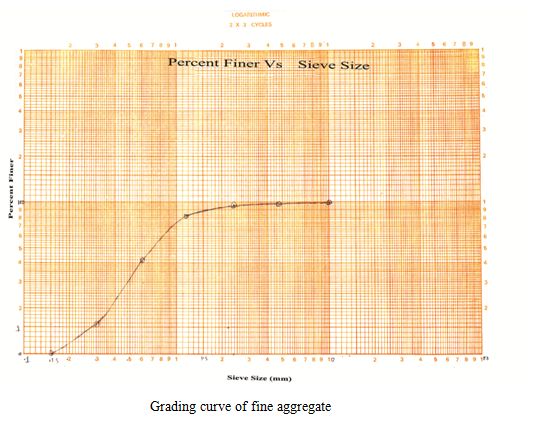

Sieve analysis of the Fine aggregate (F.M are to be determine.)

For Fine aggregate:

Data Collection:

(Sample. no-01)

Wt. of sample = 1614.10 gm

From the data sheet cumulative % retained = 263.40

So, fineness modulus = (cumulative % retained / 100)

FI: Weight of coarse aggregate

=263.40/100 = 2.63

So F.M = 2.63

Data Sheet:

Percent Finer of Fine Aggregate

Sieve number | Sieve Opening (mm) | Materials Retained (gm) | %Materials Retained | Cumulative % Retained | Percent Finer |

1.5 | 37.50 | 0 | 0 | 0 | 0 |

3/4 | 20 | 0 | 0 | 0 | 0 |

3/8 | 10 | 0 | 0 | 0 | 100 |

4 | 4.75 | 0.40 | 0.025 | 0.025 | 99.98 |

8 | 2.36 | 45 | 2.80 | 2.80 | 97.20 |

16 | 1.18 | 273.80 | 17.10 | 19.77 | 80.10 |

30 | 0.60 | 532.80 | 33.30 | 52.20 | 46.80 |

50 | 0.30 . * | 565.80 | 35.40 | 88.60 | 11.40 |

100 | 0.15 | 182 | 11.40 | 100 | 0 |

Pan : | 36 |

Calculation

Calculation

Conclusion:

Concrete is a stone like material obtained by permitting carefully proportioned mixture of cement, sand and gravel or other aggregate and water to harden in forms of the shape and dimension of the desired structure. The most important binding material is cement and lime. The inert materials used in concrete are termed as aggregates.

Bangladesh is a developing country. We have no enough material and machinery for testing materials. We have no adequate skill labor and man power.

The name of list test of aggregate are-Sieve analysis of fine aggregate and coarse aggregate. Specific gravity and absorption capacity of the fine aggregate, specific gravity and absorption capacity of the coarse aggregate. Unit weight, voids and Moisture content in aggregate.

The summery of the aggregate test result are Sieve analysis of fine aggregate(Exp. No.01) =2.63

Sieve analysis of fine aggregate(Exp. No.02)=2.65 Specific gravity and absorption capacity of the fine aggregate(Exp. No.01) The result of specific gravity Sd = 2.59, Ss = 2.61, Sa = 2.64, and the absorption capacity is A=0.70% Sieve analysis of fine aggregate(Exp. No.02)= 6.42, The result of specific gravity Sd = 2.58, Ss = 2.63, Sa = 2.64, and the absorption capacity is A=0.72% Unit Weight of Fine aggregate (Sylhet Sand) 1.552 gm/cc

Sieve analysis of coarse aggregate(Exp. No.01) =6.42 Sieve analysis of coarse aggregate(Exp. No.02) =6.40, Specific gravity and absorption capacity of the coarse aggregate(Exp. No.01) The result of specific gravity is Sd = 2.87, Ss = 2.89 and Sa = 2.90 and the absorption capacity

0.36% Specific gravity and absorption capacity of coarse aggregate. (Exp. No.02) The result of specific gravity is Sd = 2.86, Ss = 2.89 and Sa = 2.97 and the absorption capacity 1.26%. Unit Weight of Coarse aggregate (Stone chips)= 1.620, Voids in aggregate=44.50%

Compressive strength test result are primary used to determine that the concrete mixture as delivered meet the requirements of the Specified strength fc in the job Specification .Strength test result from cast cylinder may be used for quality control , acceptance of concrete , or for estimations the concrete strength in a structure for the purpose of Scheduling constriction operations such as from removal or for evaluating the adequacy of curing and protection afforded to the structure .

Recommendation

1. Fine and coarse aggregate is very necessary target result for every RCC and road side Department

2. Must be tests Fine aggregate and coarse aggregate

3. It’s should be necessary to test of aggregate from used materials.

4. It must be quality control fine aggregate and coarse aggregate.

5. Skilled work are need in use fine aggregate and coarse aggregate

6. The quality of materials brand must be controlled for the sustainable development of concrete technology.

7. Must be stone Chips or Brick Chips 25mm down graded

8. Must be Sylhet Sand F.M 1.8-2.5

9. Water absorption should not exceed 1% (for coarse aggregate)

10. The Unit weight of coarse aggregate (stone chips) should be minimum 1.60 gm/cc.

11. Water absorption should not exceed 2 %.(for fine aggregate)

12. The Unit weight of fine aggregate (Sylhet sand) should be minimum 1.50 gm/cc