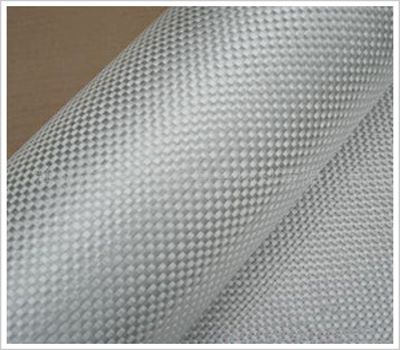

Quartz fiber is an ultra-pure silica glass that is typically processed into thin amorphous filaments of just a few micrometers (μm) in diameter. It is a fiber created from high purity natural quartz crystals. These filters are made of very pure quartz fibers with no binders and glass fibers. It is made by first softening quartz rods (in an oxyhydrogen flame) and then creating filaments from the rods. The pure quartz composition prevents the fitters from reacting with acidic gases, unlike glass fiber filters that can read and cause false readings. Since natural quartz crystals of high purity are rare, quartz fiber is more expensive than alternatives (glass fiber and high silica fiber) and has limited applications.

Quartz Fiber is made by melting natural quartz crystals of exceptional purity with a SiO2 content of 99.9% and allowing the melt to cool down in the shape and dimensions required.

Manufacture

Quartz fiber is made from heating quartz rods with an oxyhydrogen flame. Then, filaments are drawn out of the quartz rod, creating quartz fibers. Manufactured with high purity quartz, those filters are the best filtering media with high temperatures condition, because they can stand temperatures up to 900°C, and offer a very high chemical stability. For optical fibers, germanium and phosphorus can be added to increase the refractive index. Quartz glass is made by melting natural quartz crystals of exceptional purity with an SiO2 content of 99.9% and allowing the melt to cool down in the shape and dimensions required.

Properties

A single quartz fiber can have a tensile strength of 800 kilopounds per square inch (5,500 MPa). This makes quartz filters well suited for measuring heavy metal concentrations and small amounts of particles. Because of the low level of alkaline earth metals, ‘artifact’ products of sulfates and nitrates (from SO2 and NO2) are virtually eliminated. Quartz fibers are chemically stable as they are not affected by halogens. Quartz fibers also have a higher thermal resistance than S-glass or E-glass.

Applications

Since quartz fiber is expensive, it has limited applications. It is used mainly for producing composite materials and in electrical applications where thermal resistance and dielectric properties are important. It can be used in filtration applications where alternatives such as glass fiber filters cannot be used. The filters also exhibit good weight and form stability. Quartz fiber can also be used for physical devices.