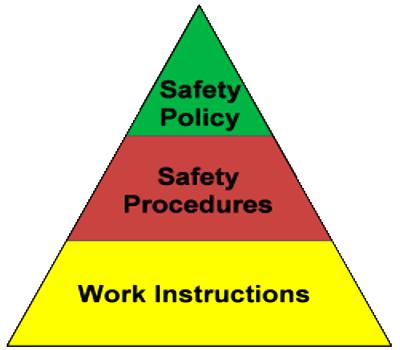

Safety Management Concepts

Safety management is commonly understood as applying a set of principles, framework, processes and measures to prevent accidents, injuries and other adverse consequences that may be caused by using a service or a product. By safety management the elimination of hazards or their control to the levels of acceptable tolerance as determined by law, regulations, ethics, personal requirements, scientific and technological capability, experimental knowledge, economics and popular practice.

A safety system of work is one which minimizes the risk of employees and others from being injured or harmed by the work activity. To achieve this required level of safety, the employer must:

- Consider modern technical standards and approved codes of practice applicable in the industry.

- Take all practicable steps to eliminate or at least minimize the risk of injury or harm from the hazard through isolation, substitution, administrative or engineering means, or the provision of PPE

- Systematically identify all hazards are significant,

- Determine which of the identified hazards are significant,

Objectives of safety management:

- To preserve the physical assets from hazardous circumstances.

- To reduce the operating costs resulting from compensation paid or cost of property damages.

- To avert the Human Resources from unsafe act resulting injuries or death.

The primary focus of safety management in aviation is on safety of flights encompassing also all associated and support services, which can have an impact on safety, for example air navigation services, aerodrome operations management, etc.

Fundamental Safety Concepts

Five fundamental safety concepts apply to any safety effort

Safety is a line responsibility. Line mangers and supervisors are responsible for the safety of their organizational units and operation.

Safety is productive. Safety is achieved by doing things right the first time, every time. Safety system ensures an extremely efficient, productive, cost-effective operation.

Safety requires upstream efforts. The selection of personnel, the ongoing and initial training, the development of procedures and the design of the facilities and equipment are the types of tasks that must be ensure safety from the top management. Good safety practices must begin as far upstream as possible. Improvements in safety can often be made for a minimal amount of money if they are made far enough upstream.

Safety depends on the safety precedence sequence. It is prioritized list of controls that should be considered as applied, in sequence, to eliminate or control identified hazards.

- Design for minimum hazard

- Provide safety devices

- Control with procedures and training

- Accept remaining residual hazards

Systematic tools and techniques help. The use of systematic methods and a systematic approach to identifying, analyzing and controlling hazards aids in reducing error rate and performing safety tasks more effectively and efficiently.

Safety measures are activities and precautions taken to improve safety or reduce risk. Common safety measures included:

- Implementation of standard procedures

- Training of employees

- Instruction Manuals

- Instructional video

- Examination of activities by specialists

- Government regulations

- Industry regulations

- Self impose regulations

- Statement of ethics

- Drug testing

- Physical examination

- Periodic examination of employees and departments

- Stress testing

- Geographical survey.

Safety management is a process of identifying and eliminating hazards that causes human injuries or property damage in an organization through

- Effective planning

- Organizing(the resources as required to avoid unsafe condition)

- Communicating(the effects of unsafe act of a person or unsafe working conditions)

- Motivating the workforce to practice safety/ personal protective equipment while in operation.

- Controlling the deviations(if any)

In order to minimize losses due to accidents and injuries and to achieve cost effective operations.

Information Source: