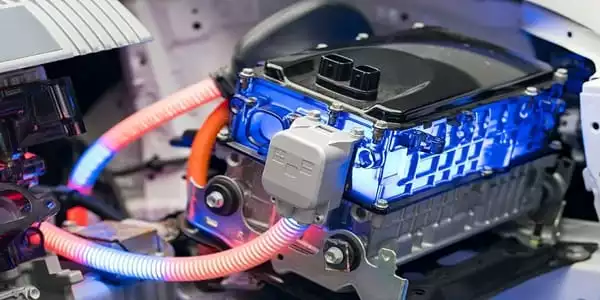

Electric vehicles (EVs) require cost-effective, safer, longer-lasting batteries that will not explode during usage or hurt the environment if they are to become mainstream. Georgia Institute of Technology researchers believe they have discovered a feasible alternative to traditional lithium-ion batteries composed of a common material: rubber.

Because of their exceptional mechanical qualities, elastomers, or synthetic rubbers, are widely employed in consumer products and advanced technology such as wearable electronics and soft robots. The researchers discovered that when built into a 3D structure, the material served as a superhighway for quick lithium-ion transport with greater mechanical robustness, resulting in longer charging batteries that can go further. The study, which was done in partnership with the Korea Advanced Institute of Science and Technology, was published in the journal Nature.

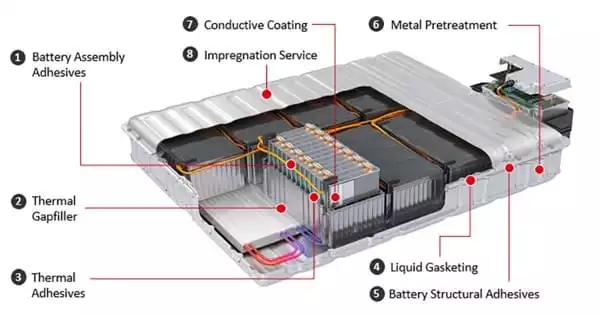

A liquid electrolyte moves ions in traditional lithium-ion batteries. However, the battery is inherently unstable: even minor damage can cause electrolyte leakage, resulting in an explosion or fire. The industry has been pushed to consider solid-state batteries, which can be produced from inorganic ceramic material or organic polymers due to safety concerns.

“The majority of the industry is focused on developing inorganic solid-state electrolytes. However, they are difficult to produce, costly, and unfriendly to the environment” Seung Woo Lee, an associate professor in the George W. Woodruff School of Mechanical Engineering, is part of a research team that discovered a rubber-based organic polymer that outperforms other materials. Solid polymer electrolytes continue to be popular due to their inexpensive manufacturing costs, non-toxicity, and soft nature. However, ordinary polymer electrolytes lack the ionic conductivity and mechanical stability required for solid-state battery reliability.

The majority of the industry is focused on developing inorganic solid-state electrolytes. However, they are difficult to produce, costly, and unfriendly to the environment. Solid polymer electrolytes continue to be popular due to their inexpensive manufacturing costs, non-toxicity, and soft nature.

Seung Woo Lee

Novel 3D Design Leads to Jump in Energy Density, Performance

Using rubber electrolytes, Georgia Tech engineers solved common difficulties (slow lithium-ion transport and poor mechanical characteristics). The ability of the material to generate a three-dimensional (3D) linked plastic crystal phase within the strong rubber matrix was a significant innovation. The high ionic conductivity, exceptional mechanical characteristics, and electrochemical stability have all been achieved as a result of this one-of-a-kind structure.

This rubber electrolyte can be created using a simple polymerization process at low temperatures, resulting in durable and smooth interfaces on the surface of electrodes. These special properties of rubber electrolytes inhibit lithium dendrite formation and allow for quicker flowing ions, allowing solid-state batteries to operate reliably even at room temperature.

“Rubber has been utilized everywhere due to its strong mechanical qualities, and it will allow us to manufacture cheaper, more reliable, and safer batteries,” Lee explained. “Higher ionic conductivity means moving more ions at the same time,” explained Michael Lee, a mechanical engineering graduate researcher. “You may boost the mileage of the EV by increasing the specific energy and energy density of these batteries.”

The researchers are now investigating ways to increase battery performance by boosting cycle time and decreasing charging time through improved ionic conductivity. So far, their efforts have resulted in a two-fold increase in battery performance/cycle time.

The work could help Georgia’s image as an EV innovation hotspot. As part of its continued collaboration with the Institute to develop next-generation solid-state batteries that are safer and more energy-dense than existing LI-ion batteries, SK Innovation, a worldwide energy, and petrochemical corporation, is financing additional research into the electrolyte material. SK Innovation recently announced the development of a new EV battery plant in Commerce, Georgia, which is planned to generate 21.5 Gigawatt-hours of lithium-ion batteries annually by 2023.

“All-solid-state batteries have the potential to significantly boost the mileage and safety of electric vehicles. Fast-growing battery businesses, such as SK Innovation, think that commercializing all-solid-state batteries will revolutionize the electric car market “Kyounghwan Choi, director of SK Innovation’s next-generation battery research center, made the statement. “There are great expectations for speedy application and commercialization of all-solid-state batteries through the current project in conjunction with SK Innovation and Professor Seung Woo Lee of Georgia Tech.”