Despite their uneven structures, natural materials such as bone, bird feathers, and wood use intelligent physical stress distribution. However, the link between stress modulation and their architecture has remained unknown. A recent study that combines machine learning, optimization, 3D printing, and stress trials has enabled engineers to gain insight into these natural wonders by creating a material that mimics the capabilities of human bone for orthopedic femur replacement.

Fractures of the femur, the long bone in the upper leg, are a common injury in humans, particularly among the elderly. The fractured edges concentrate stress at the crack tip, increasing the likelihood that the fracture may lengthen. Conventional techniques of healing a broken femur often entail surgical operations to put a metal plate over the fracture with screws, which can result in loosening, prolonged discomfort, and additional injury.

We started with materials database and used a virtual growth stimulator and machine learning algorithms to generate a virtual material, then learn the relationship between its structure and physical properties.

Shelly Zhang

The study, led by University of Illinois Urbana-Champaign civil and environmental engineering professor Shelly Zhang and graduate student Yingqi Jia, in collaboration with Peking University professor Ke Liu, introduces a novel approach to orthopedic repair that employs a fully controllable computational framework to create a bone-like material.

The study findings are published in the journal Nature Communications.

“We started with materials database and used a virtual growth stimulator and machine learning algorithms to generate a virtual material, then learn the relationship between its structure and physical properties,” Zhang said. “What separates this work from past studies is that we took things a step further by developing a computational optimization algorithm to maximize both the architecture and stress distribution we can control.”

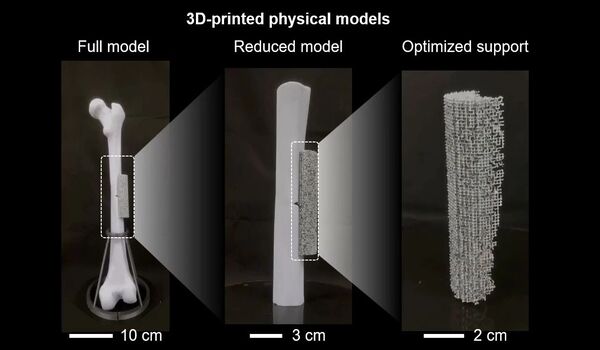

In the lab, Zhang’s team used 3D printing to fabricate a full-scale resin prototype of the new bio-inspired material and attached it to a synthetic model of a fractured human femur.

“Having a tangible model allowed us to run real-world measurements, test its efficacy and confirm that it is possible to grow a synthetic material in a way analogous to how biological systems are built,” Zhang told me. “We envision this work helping to build materials that will stimulate bone repair by providing optimized support and protection from external forces.”

Zhang stated that this technology can be applied to many biological implants where stress manipulation is required. “The method itself is quite general and can be applied to different types of materials such like metals, polymers — virtually any type of material,” stated the researcher. “The key is the geometry, local architecture and the corresponding mechanical properties, making applications almost endless.”