Sub-10-nm nanopores refer to nanopores that have a diameter smaller than 10 nanometers (nm). A nanopore is a tiny hole or channel on the nanoscale, typically on the order of nanometers, through which materials, such as molecules or ions, can pass.

Using rapid heavy ions, Chinese researchers have developed a new technique for directly fabricating sub-10 nm nanopores in WO3 nanosheets. The results have been published in Nano Letters.

The scientists at the Materials Research Center of the Institute of Modern Physics (IMP) of the Chinese Academy of Sciences (CAS) and their collaborator at the Joint Institute conducted the study for Nuclear Research, Russia.

The creation of high-quality solid-state nanopores is crucial for the use of nanofluidic devices, nanofiltration membranes, and single molecule detection. The most popular way to fabricate nanopores in inorganic films, such as SiN, SiO2 and Al2O3, is to use focused ion or electron beams.

However, this pouring technique requires a feedback mechanism or direct imaging, and only one nanopore may be created at a time, which restricts bulk production. Therefore, it is essential to investigate a novel poring technique that may produce nanopores with adjustable size and density without the use of a feedback mechanism.

Sub-10-nm nanopores are particularly interesting and valuable because they allow the passage of small molecules and ions, including single-stranded DNA, RNA, proteins, and ions, which can have significant implications in many areas, such as DNA sequencing, biomolecule analysis, and drug delivery.

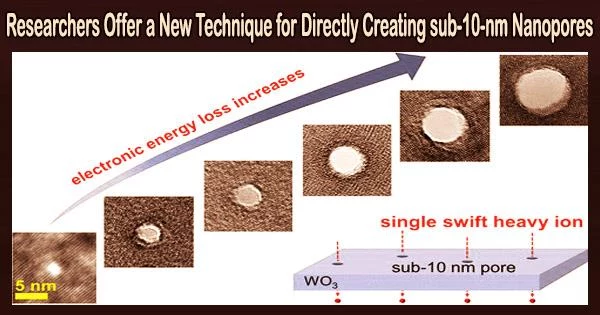

Based on the Heavy Ion Research Facility in Lanzhou (HIRFL), the scientists have demonstrated a direct poring method in WO3 nanosheets using swift heavy ion irradiation.

In order to further clarify the underlying mechanism, they also used molecular dynamics simulations. It was discovered that the primary causes of nanopore creation are the viscosity and surface tension of the transitory molten phase brought on by fast heavy ions.

By selecting ions of different electronic energy losses, the scientists created nanopores with sizes from 1.8 to 7.4 nm in WO3 nanosheets. They can control the density of nanopores by applying different ion fluences.

This novel technique, which does not need a chemical etching procedure, offers broad promise. It opens the door to creating solid-state nanopores in materials with low surface tension and viscosity while also shedding fresh light on how latent ion tracks form in solids.