Recovering valuable resources from wastewater sludge is a critical component of long-term wastewater treatment and resource management. The solid residue left behind after wastewater treatment plants is known as wastewater sludge. While it does contain pollutants and pathogens that must be managed carefully, it also contains valuable resources that can be recovered and reused.

If you were to look at sewage sludge up close, you might not think it has any redeemable value; however, researchers at UBC’s Bioreactor Technology Group see it differently.

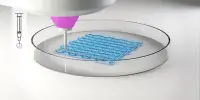

UBC researchers have developed a cost-effective method for concentrating phosphorus from wastewater sludge, which can be recovered efficiently through extraction, using a combination of heat, water, and phase separation.

“Phosphorus is a non-renewable, but essential, element for life, and it has many industrial uses,” explains Huan Liu, a doctoral student in UBCO’s School of Engineering and the lead author of a new study investigating this method.

We were able to identify, for the first time, the kinetic reactions of phosphorus leaching from hydrochar in order to optimize the recovery of useful materials, such as what is needed for fertilizer.

Huan Liu

Phosphorus is a natural mineral that is essential for human health and food security as a commercial fertilizer; however, it is also listed as a critical raw material due to the reliance of many countries on imports.

“The uneven distribution of phosphate rock has created political and economic risks,” he says. “On the other hand, phosphorus discharge from waste sources, such as wastewater, is a major contributor to aquatic eutrophication, causing severe environmental challenges including algae blooms and dead zones in lakes.”

Liu and his supervisor, principal investigator Dr. Cigdem Eskicioglu, are investigating a promising process that integrates hydrothermal liquefaction.

The process converts organic components of municipal wastewater sludge into a petroleum-like bio-crude and concentrates phosphorus into hydrochar, a solid residue. The total phosphorus content of hydrochar can be 100 times that of raw sludge, making it comparable to the phosphate rock used in commercial fertilizers.

Liu compares the extraction process to what happens when minerals and acids are combined. “We were able to identify, for the first time, the kinetic reactions of phosphorus leaching from hydrochar in order to optimize the recovery of useful materials, such as what is needed for fertilizer,” Liu says.

Dr. Eskicioglu believes that their latest findings are critical for wastewater utilities looking to develop a process to recover usable nutrients from the system.

“At a time when we are striving to be more sustainable and seek alternative fuels, extruding useful materials from waste is critical,” she says. “Recovery and recycling is the solution that has the added benefit of providing a secondary source of phosphorus that can be distributed globally while also aiding in environmental conservation.”