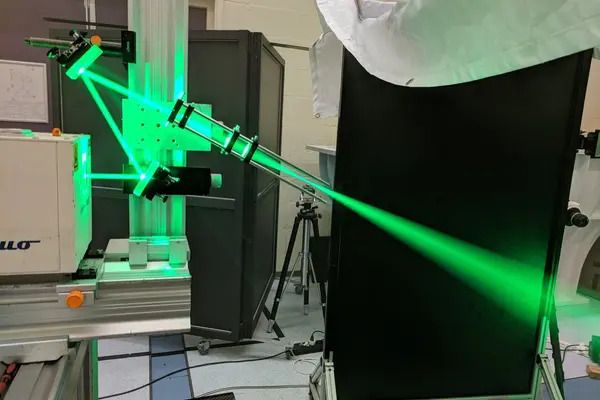

A novel laboratory method employs a high-accuracy ball delivery equipment and a speed measurement system to provide improved insight into how high and far certain of those baseballs will fly. As the Major League Baseball season begins, many fans of America’s third most popular sport wonder how many home runs they will see this season.

A novel laboratory method employs a high-accuracy ball delivery equipment and a speed measurement system to provide improved insight into how high and far certain of those baseballs will fly.

In a paper published in the journal Applied Sciences, researchers from Washington State University and Delft University of Technology describe a new technique that involves firing baseballs through a line of sensors and monitoring the change in speed as they travel along a trajectory. The technique is more precise than standard wind tunnel measurements because it does not require the ball to rest on a perched platform, which introduces a small but significant inaccuracy.

“My lab happens to perform the most accurate test in the world of this property,” said Lloyd Smith, a professor in the School of Mechanical and Materials Engineering and principal author of the study. “Not many people care about lift and drag to the level that we do, but people do care in baseball games.”

While baseball is a popular sport, the aerodynamic properties of baseballs have not been fully understood. It turns out that very small changes in drag can matter a lot in the game, Smith said.

My lab happens to perform the most accurate test in the world of this property. Not many people care about lift and drag to the level that we do, but people do care in baseball games.

Lloyd Smith

Major League Baseball only employs one manufacturer, Rawlings Sporting Goods, to ensure a uniform and consistent playing experience, and the balls are made according to tight regulations. The ball contains a cork rubber pill wrapped in three layers of a specified weight of wool and covered with leather. The pill, wool, and leather are meticulously designed, measured, and controlled; even the color of the rubber must be uniform. The company employs almost 200 people merely to precisely stitch the seams on baseballs.

“I never thought in my wildest dreams that I would be differentiating between belly leather and back leather on a ball, but I am, and it turns out that the two kinds of leather are different on a ball, and you’ll find less belly leather than you would have a few years ago,” said Smith.

Everything is measured to be uniform, including the ball’s weight, size, hardness and elasticity, and to maintain fair play, Major League Baseball rules even require that the ball only be used for one play before it’s discarded. In spite of that uniformity, starting in 2015 and with virtually the same baseball, hitters started making a lot more homeruns.

“The assumption was that if you made the ball the same way, that those properties would always come out the same way,” said Smith. “We found out that something changed.”

When the Major League Baseball organization commissioned a team to investigate the unexpected and dramatic change, researchers discovered that a mere 3% decrease in the ball’s aerodynamic drag was responsible for the remarkable increase in home runs. They discovered that a modest alteration in the height of the ball’s seams could have caused at least some of the shift.

However, during their researches, the researchers discovered that wind tunnel testing methodologies could not sufficiently capture the minor variations in drag that could make a significant difference in home runs. Wind tunnels are used to measure drag forces in everything from airplane wings to automobiles and bicycles, but they are not suitable for baseballs.

“You have to hold onto the ball in some way,” said Smith, “and that means there’s always going to be some imperfection when you’re using a wind tunnel to measure drag.”

The researchers used their laser-guided speed measurement device to precisely record changes in speed and then calculate acceleration, forces on the ball, and lift and drag.

“We had to go back and look at what we can do to make this even more accurate, and we did,” Smith explained. “It hasn’t been simple to do, and we spend a lot of time calibrating every day just to make sure that our sensors are telling us what we think they are, but we now believe that the drag measurements we’re making are going to be able to sound the alarm if there’s a change.”