Introduction:

Industrial attachment is the first of professional life of student, especially to the technical side. In the university the production machines are not available, so for further learning Industrial training is essential. So 6 week training program was arranged for us.

Textile education can’t be completed without industrial training. Because this industrial attachment program minimizes the gap between the theoretical and practical knowledge. I got an opportunity to complete my industrial training in the RAHMAT KNIT-DYEING & FINSHING LTD. Which is an export oriented Composite Knit Dyeing industry. It has well planed & equipped Fabric and Dyeing – Finishing units in addition to facilitate Knitting and Knitwear manufacturing.

Chapter -1

Project description

General information about the factory:

COMPANY PROFILE

Name of the project : RAHMAT KNIT-DYEING & FINSHING LTD.

Type of the project : 100% EXPORT ORIENTED KNITWEAR INDUSTRY LTD.

Year of establishment : It was established in 1988.

Address : Mouchak, Kaliakoir, Gazipur, Bangladesh.

Head office : 195, Senakalyan Bhaban 14th Floor, Motijheel C/A, Dhaka, Dhaka, Bangladesh

Vision of the Project :

To produce quality product.

To survive in the Global market.

Mission of the Project :

Its mission is to produce the latest design quality Knit Fabrics and apparels for international market.

History of the Project : RAHMAT KNIT-DYEING & FINSHING LTD. has started manufacture and export of Garments since 1988.

Annual Production capacity:

The annual production capacity of RAHMAT KNIT-DYEING & FINSHING LTD are given bellow,

Dyeing & Finishing Capacity : 3662 Tons.

Knitting Capacity : 2520 Tons

The actual capacity of the RAHMAT KNIT-DYEING &S FINSHING LTD may vary, due to the order capacity.

Buyer:

1. H &M.

2. ITPS.

3. Cello.

4. Puma.

5. Slanzeger.

Certification & award : Within the very short time RAHMOT KNIT-DYEING $ FINSHING LTD have become one of the few Garments house in the Bangladesh that obtain ISO 9001 certificate.

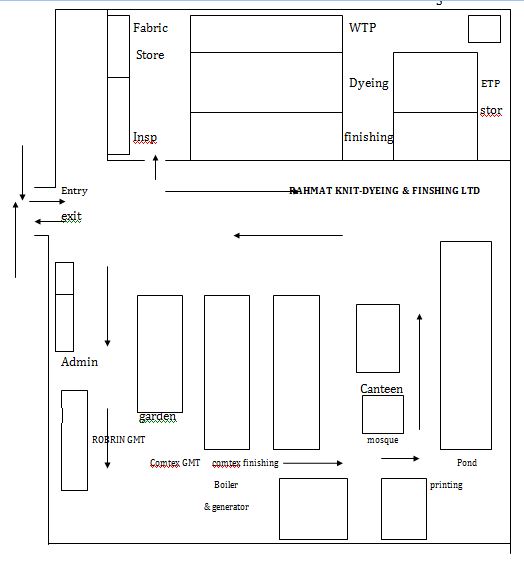

Project Layout:

Production capacity :

Dyeing & Finishing Capacity : 3662 Tons/year

Knitting Capacity : 2520 Tons/ year

Remark : RAHMAT KNIT-DYEING & FINSHING LTD is a profitable project and contributing in our National economy.

Chapter -2

Human Resource Management

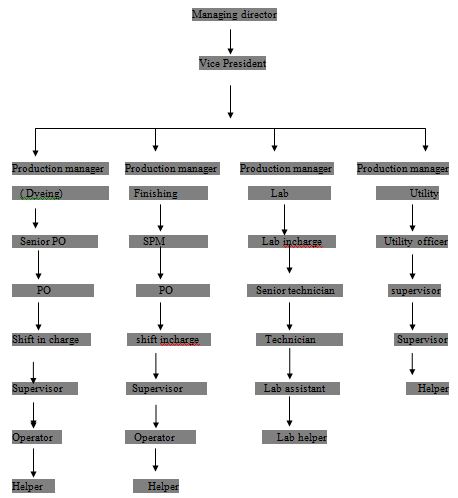

Management System :The overall management system is controlled by the administration department. In administration department the following persons are included, Managing Director (MD ),Vice President, General Manager and other respective person, who do their respective job and finally control the overall management system of the whole factory.

Organogram of the Dyeing department:

Vice President

Production manager Production manager Production manager Production manager

( Dyeing) Finishing Lab Utility

Senior PO SPM Lab incharge Utility officer

PO PO Senior technician supervisor

Shift in charge shift incharge Technician Supervisor

Supervisor Supervisor Lab assistant Helper

Operator Operator Lab helper

Helper Helper

Promotion: In the factory the promotion of the respective officer and also for the worker is done by observing their performance, responsibility, working ability during working hour. If any person can satisfy these virtues, this person will be eligible for promotion.

Safety in workplaces: During the working hour, and Chemical handling the worker maintain the following things,

Hand gloves.

Apron.

Safety Glass.

Ear plug.

Rubber boat.

Job responsibility of employees:

Production Manager:

• To plan for the sequence of operation.

• To follow the raw material, so that it does not mix with another batch.

• To follow the production and give the solution for particular problems.

• To follow up the instruction of the Managing Director, and senior advice.

Production Officer:

• To follow up the instruction of the Production Manager.

• To follow up the production process.

• To guide the supervisors.

• To find out the probable causes for less production.

Supervisor :

• To guide the operator and helper during the working time.

• To check the chemicals and Dyes, whither it is maintain properly or not.

• To collect the Samples.

Laboratory officer:

• To check the sample correctly.

• Supply the accurate Recipe to the production.

• To maintain the Data color accurately.

• Calibrate the Data color properly.

• Carefully prepare the stock solution of the Dyes and Chemicals.

Chapter -3

Machine Description

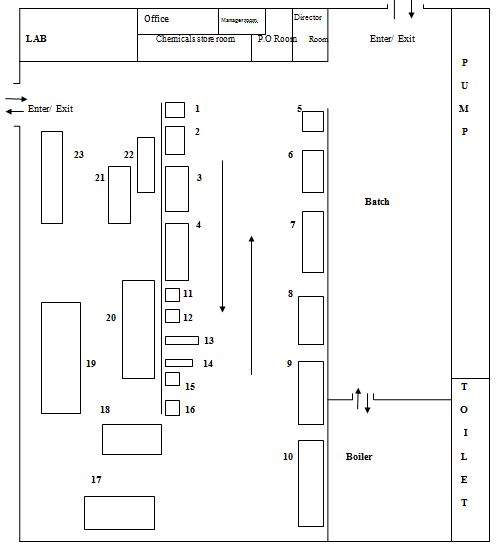

Layout of Rahamat knit dyeing & finishing: N

Machine description of knitting section:

The following types of machines are used in the RAHMAT GROUP Knitting section

1. Machine Name : Zentex

Machine type : Double Jersey

Origin : Singapore

Machine Diameter : 20 inch

Machine Gauge : 24

Number of feeder : 40

Machine Track : 4

2. Machine Name : Zentex

Machine type : Double Jersey

Origin : Singapore

Machine Diameter : 25 inch

Machine Gauge : 24

Number of feeder : 52

Machine Track : 4

3. Machine Name : Zentex

Machine type :Double Jersey

Origin : Singapore

Machine Diameter : 18 inch

Machine Gauge : 20

Number of feeder : 36

Machine Track : 4

4. Machine Name : Zentex

Machine type : Double Jersey

Origin : Singapore

Machine Diameter : 16 inch

Machine Gauge : 20

Number of feeder : 32

Machine Track : 4

5. Machine Name : Zentex

Machine type : Double Jersey

Origin : Singapore

Machine Diameter : 14 inch

Machine Gauge : 20

Number of feeder : 28

Machine Track : 4

6. Machine Name : Falmac

Machine type : Single Jersey

Origin : Singapore

Machine Diameter : 21 inch

Machine Gauge : 24

Number of feeder : 63

Machine Track : 4

7. Machine Name : Zentex

Machine type : Single Jersey

Origin : Singapore

Machine Diameter : 22 inch

Machine Gauge : 24

Number of feeder : 54

Machine Track : 4

8. Machine Name : Falmac

Machine type : Single Jersey

Origin : Singapore

Machine Diameter : 18 inch

Machine Gauge : 24

Number of feeder : 54

Machine Track : 4

9. Machine Name : Falmac

Machine type : Single Jersey

Origin : Singapore

Machine Diameter : 23 inch

Machine Gauge : 24

Number of feeder : 69

Machine Track : 4

10. Machine Name : Zentex

Machine type : Double Jersey

Origin : Singapore

Machine Diameter : 24 inch

Machine Gauge : 24

Number of feeder : 48

Machine Track : 4

11. Machine Name : Zentex

Machine type : Double Jersey

Origin : Singapore

Machine Diameter : 22 inch

Machine Gauge : 24

Number of feeder : 44

Machine Track : 4

12. Machine Name : Zentex

Machine type : Double Jersey

Origin : Singapore

Machine Diameter : 16 inch

Machine Gauge : 20

Number of feeder : 32

Machine Track : 4

13. Machine Name : Zentex

Machine type : Double Jersey

Origin : Singapore

Machine Diameter : 14 inch

Machine Gauge : 20

Number of feeder : 28

Machine Track : 4

14. Machine Name : Zentex

Machine type : Double Jersey

Origin : Singapore

Machine Diameter : 20 inch

Machine Gauge : 24

Number of feeder : 40

Machine Track : 4

15. Machine Name : Zentex

Machine type : Single Jersey

Origin : Singapore

Machine Diameter : 19 inch

Machine Gauge : 24

Number of feeder : 57

Machine Track : 4

16. Machine Name : Ban Yan

Model Number : MS-0301 M

Machine type : Single Jersey (Open Dia)

Origin : Taiwan

Machine Diameter : 38 inch

Machine Gauge : 24

Number of feeder : 108

Machine Track : 4

17. Machine Name : Ban Yan

Model Number : MS-0301 M

Machine type : Single Jersey (Open Dia)

Origin : Taiwan

Machine Diameter : 36 inch

Machine Gauge : 24

Number of feeder : 108

Machine Track : 4

18. Machine Name : Ban Yan

Machine type : Single Jersey (Open Dia)

Model Number : MS-0301 M

Origin : Taiwan

Machine Diameter : 36 inch

Machine Gauge : 24

Number of feeder : 108

Machine Track : 4

19. Machine Name : Ban Yan

Machine type : Single Jersey (Open Dia)

Model Number : MS-0301 M

Origin : Taiwan

Machine Diameter : 36 inch

Machine Gauge : 24

Number of feeder : 108

Machine Track : 4

20. Machine Name : Ban Yan

Machine type : Single Jersey (Open Dia)

Model Number : 90 KJ

Origin : Taiwan

Machine Diameter : 36inch

Machine Gauge : 24

Number of feeder : 108

Machine Track : 4

Machine description of Dyeing Section:

List of machinery in dyeing section:

1. Machine name : Fong’s

Model no. : T 737XL

Origin : China

M : L : 1 : 8

Maximum Temperature: 135 Deg

Design Capacity : 200 Kg

2. Machine name :Fong’s

Model no. : T 737XL

Origin : China

M : L : 1 : 8

Maximum Temperature: 135 Deg

Design Capacity : 500 Kg

3. Machine name : Fong’s

Model no. : ST828EX

Origin : China

M : L : 1 : 8

Maximum Temperature : 135 Deg

Design Capacity : 700 Kg

4. Machine name : Fong’s

Model no. : ST828EX

Origin : China

M : L : 1 : 8

Maximum Temperature : 135 Deg

Design Capacity : 1000 Kg

5. Machine name : Slavos

Model no. : 5000

Origin : Greece

M : L : 1 : 8

Maximum Temperature : 135 Deg

Design Capacity : 200 Kg

6. Machine name : Slavos

Model no. : 5000

Origin : Greece

M : L : 1 : 8

Maximum Temperature : 135 Deg

Design Capacity : 400 Kg

7. Machine name : Slavos

Model no. : 5000

Origin : Greece

M : L : 1 : 8

Maximum Temperature : 135 Deg

Design Capacity : 700 Kg

8. Machine name : Slavos

Model no. : 5000

Origin : Greece

M : L : 1 : 8

Maximum Temperature : 135 Deg

Design Capacity :400 Kg

9. Machine name : Slavos

Model no. : 5000

Origin : Greece

M : L : 1 : 8

Maximum Temperature : 135 Deg

Design Capacity : 700 Kg

10. Machine name : Slavos

Model no. : 5000

Origin : Greece

M : L : 1 : 8

Maximum Temperature : 135 Deg

Design Capacity : 1000 Kg

Sample dyeing Machine Description :

11. Machine name :Thies

Model no. : T 737XL

Origin : Germany

M : L : 1 : 8

Maximum Temperature : 135 Deg

Design Capacity : 20 Kg

12. Machine name :Thies

Model no. : T 737XL

Origin : Germany

M : L : 1 : 8

Maximum Temperature : 135 Deg

Design Capacity : 20 Kg

13. Machine name :Fong’s

Model no. : T 737XL

Origin : China

M : L : 1 : 8

Maximum Temperature : 135 Deg

Design Capacity : 90 Kg

14. Machine name :Fong’s

Model no. : T 737XL

Origin : China

M : L : 1 : 8

Maximum Temperature : 135 Deg

Design Capacity : 40 Kg

15. Machine name :Thies

Model no. : T 737XL

Origin : Germany

M : L : 1 : 8

Maximum Temperature : 135 Deg

Design Capacity : 20 Kg

\

16. Machine name :Thies

Model no. : T 737XL

Origin : Germany

M : L : 1 : 8

Maximum Temperature : 135 Deg

Design Capacity : 20 Kg

Finishing Section:

List of Machinery in the finishing section:

Machine Type Quantity

Dryer Machine 2 Pcs

Squeezer 2 Pcs

Compactor Machine 2 Pcs

Specification of Finishing section Machinery:

17. Machine Name : Suntex

Machine Type : Squeezer

Model no : 5522

Serial number : 02-5522

Origin : Switzerland

Maximum speed : 100 RPM

Roller pressure :0.2 bar

Number of Roller : 4

18. Machine Name : Tube tex

Machine Type : Squeezer

Model no : BM- 9186

Serial number : 3685108.

Origin : U.S.A

Serial no. : 1323

Maximum speed : 100 RPM

Roller pressure :0.18 bar

Number of Roller : 4

Object of the Squeezer:

• Softener is used in this machine to soft the fabric.

• To increase the diameter of the fabric.

• To decrease the diameter of the fabric.

19. Machine Name : LK

Machine Type : Fabric Dryer

Model no : ET-8

Origin : Taiwan

Number of Chamber : 6

Number of Motor : 11

Number of belt : 6

Number of Fabric feed : 3 Piece of Tube Fabric

Maximum speed : 24 RPM

Number of Burner : 5

Maximum Heat : 220 Deg.

Object of the Fabric dryer:

• To dry the finished Fabric.

• To give the fabric surface smooth

20. Machine Name : Ngai Shing

Machine Type : Tumble Dryer

Model no : NS- 2320

Origin : Hong Kong

Serial no. : 1323

Maximum speed : 12 RPM

Maximum Capacity : (20-22) kg

Maximum Heat : 200 Deg.

Object of the Tumble dryer:

To increase the GSM.

To dry the sample fabric.

Sometime use for sophisticated fabric drying.

In case of making the fabric color deep.

21. Machine Name : Tube tex

Machine Type : Compactor

Model no : BM- 9809.

Origin : U.S.A

Serial no. : 6047483

Maximum speed : (12-13) RPM

Far Roller pressure : 18 psi

Near Roller pressure : 16 psi

Shoe pressure : 10.5 psi

22. Machine Name : Tube tex

Machine Type : Compactor

Model no : BM- 9809.

Origin : U.S.A

Serial no. : 6047483

Maximum speed : (12-13) RPM

Far Roller pressure : 18 psi

Near Roller pressure: 16 psi

Shoe pressure : 10.5 psi

Object of the Fabric dryer:

To increase the GSM of the fabric.

To control the shrinkage of the fabric.

To compact the fabric.

To control the Drape and handle property of the fabric.

Finished Fabric inspection:

Name : Grey Fabric inspection

Model number: UZ-F series.

Manufacturer : AATPR industries co Ltd.

Origin : Thailand

Object: To find out the defect of the finished fabric

Lab section

List of machine in lab section:

Machine Type Quantity

Lab machine 3 pc

Data color 1 pc

Washing machine 1 pc

Mixture machine 1 pc

Labtec dryer 1 pc

Light source:

• D- 65 ( artificial day light)

• UV- Ultra violet.

• TL- 83 TL- 84

• F-Florescent

• Mercury bulb

Remark: The machinery of the RAHMAT KNIT-DYEING & FINSHING LTD is the modern machinery .Day by day they are thinking to install the new brand of machinery in their factory. Recently they have decided to install the stenter machine and other modern machine in the factory.

Chapter- 4

Raw Materials

In t RAHMAT KNIT-DYEING & FINSHING LTD he raw materials used for the production are:

• Grey Yarn.

• Grey Fabric.

• Chemicals.

• Dyes.

Grey Yarn:

The grey Yarn is used in the manufacturing of Knitted fabrics. The following types of yarns are used in the manufacturing of Knitted fabrics,

• Cotton Yarn (24, 30,34,40)

• Polyester Yarn ( 75 count)

• Lycra ( 20 D)

•

Grey Fabric:

The following types of grey Knitted fabrics are dyed in the Industry,

• Plain fabrics (single jersey).

• Rib fabrics (double jersey).

• Double pique.

• Double Lacoust .

Sources: The required grey Yarns are collected from different spinning industry .Some of the industries name are included here,

• Foysal Spinning.

• Youth spinning.

• Metro Spinning.

• Etc.

The required amounts of grey fabrics are prepared in the industry.

Types of Raw Material:

For Knitting:

1. Spun yarn :

• 100% cotton.

• PC (Polyester- cotton blend) 65% Polyester and 35% Cotton.

• Grey Melanges composed of 85% Cotton and 15% Viscose.

• Polyester.

•

2. Filament Yarn:

• Polyester.

• Viscose.

• Spandex (Lycra)

Sources:

• India.

• Indorama LTD ( Indonesia)

• Pakistan.

For dyeing:

• Grey fabrics.

• Chemicals

• Dyes.

The sources of dyes and chemicals are given bellow:

• Ciba,BASF,Claient, H.P chemical, Dyestuff, Chemtek ,Rudolf , Hamza,Dyechufix ,etc

The different types of dyes, chemicals prices are included bellow:

Chemical Name Price (BDT) Per Kg/Lit

Acetic acid 58

Hydrogen per oxide 29

Caustic Soda 56

Gluber Salt 9

Common Salt 9

Soda Ash 17

Novostone L Conc 500

Chem Crease 60

Chem Quest 100L 120

Tricar -P 108

Cottoclarin BLN 102

Chem Percat 555 Y 98

Disperca EP 108

Setafix WW 175

Besosoft F EUK 200

Skyehite BVB 450

Hydrosulphite 175

Domapal B Conc 240

Dychufix Black GR 245

Dychufix Blue BRXF 1200

Dychufix Red EC 800

Synozol Ultra Black DR 408

Synozol Red KHL 1549

Synozol Blue KHL 1758

Terasil Navy WRS 1600

Terasil Red W4BS 925

Dyes used in dyeing:

Serial Number Dyes Name

1 Dychufix Black GR

2 Dychufix Blue BR XF

3 Dychufix Orange 2RXF

4

Dychufix Navy Blue EC

5 Dychufix

6 Dychufix Black B

7 Synozol Ultra Black DR

8 Synozol Red K3BS

9 Synozol Yellow KHL

10 Synozol Navy blue KBF

11 Synozol Red KHL

12 Synozol Blue KHL

13 Remazol B. Yellow 3GL

14 Remazol Blue RSPL

15 Remazol Blue RR

16 Remazol Yellow RR

17 Remazol Red RR

18 Livafix Red CA

19 Livafix Orange CA

20 Livafix Blue CA

21 Novacron S3R

22 Novacron Deep Red S 3B

23 Novacron S. Black G

24 Setazol Red 3BS

25 Setazol Yellow 3RS

26 Setazol Blue BRFBlack TMS

27 Setazol T-Blue GN

28 Terasil Navy WRS

29 Terasil Red W4BS

30 Terasil Red WWBFS

31 Terasil Black WNS

32 Terasil Blue WBLS

33 Drimare Orange CL3R

34 Drimare Red CL5B

35 Drimare Blue CLBR

36 Cibacron Orange FBR

37 Cibacron Orange W3RRed FN

38 Cibacron Red FN2BL

39 Cibacron Scarlet F3G

40 Cibacron Yellow HG

41 Cibacron Blue FGFN

42 Cibacron Navy FNB

43 Cibacron Red HFN

Chemicals used in Dyeing:

1. Bleaching agent:

• Acetic acid

• Hydrogen per oxide

• Caustic Soda

• Soda ash

2. Salt / Electrolight:

• Common Salt

• Gluber salt

3. Sequestering agent:

• Chemquest 1000 L

4. Anticreasing agen:

• Lubrica SB

• Chemcrease

5. Enzyme Finishing agent:

• CX Ultra

• Bio polish EC

6. Levelling agent:

• Tricar- P

7. Detergent :

• Foryl –BGL

• Cottoclarin BLN

8. Peroxide killer:

• Rucorit WEZ

• Chem percat 555Y

9. Peroxide stabilizer:

• Rucostab OKB

10. Antifoaming agent :

• Albaflow jet

• Rustol ASA

11. Soaping agent:

• Dispercar EP

12. Fixing agent:

• Setafix WW

• Setafix R

• Albafix FRD

• Temofix FR

13. Color Softener:

• Sapamine CWS

• Decosoft JCC

14. White softener:

• Belsoft 200

• Belsoft F EUK

• Kepasoft BD

15. Reducing :

• Hydrosulphite

16. Optical Brightening Agent:

• Skywhite BVB

• Uvitex 2B

• Uvitex BBT

• Blankophor BBU

Sources: Dyeing department of RAHMOT GROUP collect the grey fabric from the Knitting department. According to the buyer requirement the store officer receives the grey fabric. Finally when Dyeing Department need the grey fabric for Dyeing, the respective store officer supply the grey fabric.

The store officer of Dyes and Chemicals receive the goods and stored it. Store officer send the requisition to the head of the Dyeing department according to the requirement when the Dyes and chemicals has little in stock. Finally as per requisition L/C has been opened or purchased from the local market.

Remark: It is necessary to maintain the good qualities Dyes and Chemicals for good dyeing. The mentioned Dyes and Chemicals are very good in quality.

Chapter -5

Production Management

Production parameter:

Parameter for Knitting:

• GSM of fabric.

• Stitch length.

• Fabric dia.

• Gauge of the machine.

Parameter for Dyeing:

• pH of the Dye bath.

• Temperature of dyeing.

• Time of dyeing.

• M:L ratio.

• Reel speed.

• Pump speed.

• Concentration of Dyes and chemicals.

Production process:

Chemicals needed for the process of Dyeing,

Chemical name Brand name percentage

Bleaching Agent H2O2 (3 to5) gpl on the basis of shade

Scouring Agent NaOH 4 gpl

Soaping Agent Dispercar EP 0.5 % to 1.0 gpl

Peroxide killer Rucozrit WEZ BASE 1.0 gpl

Acid for neutralization CH3COOH 1.0% according to requirement

Enzyme Bio polish EC 1.0 to 1.5 gpl

Levelling Agent Albatex DBC 0.5 to 1.0 gpl

Anticreasing Agent Chem crease 0.5 to 1.5 gpl

Soda ash NaCO3 6 to 20 gpl

Caustic soda NaOH 0.5 gpl

Fixing Agent Setafix WW 0.5 to 1.0 gpl

Softener Belsoft 200 1.0 to 1.5 gpl

Sequestering Agent Chem Quest 1000 L 0.5 to 1.0gpl

Stabilizer Rucostab OKB 0.5 to 1.5 gpl ( on the bqsis of H2O2)

Antifoaming Agent Rustol ASA 0.5 gpl

Amount of salt soda require for Dyeing:

Here M:L ratio is 1: 8

| Shade% | <0.1 | <0.5 | <1.0 | <1.5 | <2.0 | <2.5 | <3.0 | <3.5 | <4.0 | <4.5 | <5.0 |

| Soda ashGpl | 5 | 6 | 8 | 10 | 10 | 12 | 15 | 15 | 15 | 18 | 18 |

| SaltGpl | 20 | 24 | 30 | 40 | 40 | 50 | 60 | 60 | 60 | 70 | 70 |

Batching: Batching is the process to divided the Fabric according to the capacity machine and their nozzle. For any particular type of machine the batching will be different.

Purpose of Batching:

• To divide the fabric according to the M/C capacity.

• To observe the lot variation.

• To divide the Rib Fabric equally with all nozzle.

• To turn out the fabric into back side.

Batch Management: Primary batching is done by Dyeing Manager. Taking the above criteria under consideration the respective person done the batching. Sometime plan is adjusted according to the M/C condition.

Sequence of Operation:

Grey fabric inspection

Batching

Fabric turning

Loading on the M/C

Pretreatment ( Scouring & Bleaching )

Dyeing

Squeezing

Drying

Compacting

Final inspection & packing

Inventory system for Raw material:

Grey fabrics: Supplied from factory own Knitting department.

Dyes and Chemicals: Purchased from local market or imported from foreign country.

Spares: store officer keep the spare parts into the store and make a list of the spare parts. If the spare parts are little in stock then requisition is supplied to the authority.

Packing material: Purchased from local or foreign market.

Procurement system:

• Directly cash purchased

• L/C purchased

• Local purchased

• Imported purchased

Finished goods Inventory: finished fabrics from the compactor go to the inspection team. From the inspection table the fabric weighted in electric balance. And finally it go to the finished fabric store room. Here finished fabric store officer store the fabrics. After the requirement of the Garments the finished fabrics is send to the Garments.

Remark: It is very necessary to maintain the stock report in the store daily. So the store officer maintains the daily stock.

Chapter -6

Process Description

Dyeing process description: Dyeing production process depend on the basis of shade percentage. The process of Light, Medium Deep Shade is different. Here the three process and as well as Turquoise color processes are described;

Light Shade:

M/C no :03

Fabric type : Single Jersey

Color : Pink

Special instruction: Enzyme washes

Yarn count : 34 s

Buyer : H&M

Fabric GSM : 150

Fabric Weight : 680 Kg

M: L : 1 : 8

Recipe:

Name of the Chemicals | g/l | % |

| BLN | 1.0 | |

| 1000L | 0.80 | |

| Lubrica SB | 1.50 | |

| OKB | 0.30 | |

| ASA | 0.3 | |

| NaOH | 3.0 | |

| H2O2 | 4.0 | |

| Acetic acid | 1.0 | |

| WEZ | 0.50 | |

| Bio polish | 0.30 | |

| DBC | 1.00 | |

| Lubrica SB | 1.50 | |

| Gluber salt | 40.0 | |

| Seta Yellow 3RS | 0.0121 | |

| Seta Red 3BS | 0.0555 | |

| Seta Blue BRF | 0.01063 | |

| Soda | 15.0 | |

| Acetic acid | 1.00 | |

| Dispercar EP | 0.50 | |

| Acetic acid | 0.20 | |

| CWS | 1.50 |

Pretreatment:

Process flowchart of Scouring and Bleaching:

Fabric loaded on the machine

Machine filled with water

All pretreatment Chemicals inject at 60° C

NaOH dozing for 10 minute at

Raise the temperature to 110° C

Run for 30 min

Cooling at 80° c

Rinse at 80° C

Run time 10 min

Cooling at 50° C

Drain the liquor

Process flow chart of Enzyme:

Machine filled with water

Acetic acid inject

Peroxide killer inject

pH check ( 4 to 4.5 ) ( If not ok )

Enzyme inject

Raise the temperature to 55° C

Run for 30 min

Sample cutting ( if ok)

Drain the liquor

Dyeing & Finishing:

Production process sequence for 100% Cotton Fabric (Light Shade) :

Fabric loaded on the machine

Machine filled with water according to the requirement

All pretreatment Chemicals inject at 60° C

NaOH dozing for 10 minute at

Raise the temperature to 110° C

Run for 30 min

Cooling at 80° c

Rinse at 80° C

Run time 10 min

Cooling at 50° C

Drain the liquor

Machine filled with water according to the requirement

Acetic acid inject

Peroxide killer inject

pH check ( 4 to 4.5 ) ( If not ok )

Enzyme inject

Raise the temperature to 55° C

Run for 30 min

Sample cutting ( if ok)

Drain the liquor

Normal wash at 40C for 10 min

Drain the water

Levelling & Lubrica SB inject at 60 C

All salt inject at 60 c

Color dozing at 60C for 40 min

Run for 15 min

Soda dozing at 60C for 45 min

Run for 1 hr

If CMC is ok then drop the liquor

acid wash at 40 C for 10 min

Normal hot at 70c for 10 min

Fixing agent at 40C and run for 10 min

Normal wash

Softener inject at 40 C for 15 min

Wash and unload the material

Medium Shade:

M/C no : 05

Fabric type : Double Pique

Color : Gold

Special instruction: Enzyme wash

Yarn count : 24 s

Buyer : H&M

Fabric GSM : 200

Fabric Weight : 620 Kg

M: L : 1 : 8

Recipe:

Name of the Chemicals | g/l | % |

| BLN | 1.0 | |

| 1000L | 0.80 | |

| Lubrica SB | 1.50 | |

| OKB | 0.30 | |

| ASA | 0.3 | |

| NaOH | 3.0 | |

| H2O2 | 4.0 | |

| Acetic acid | 1.0 | |

| WEZ | 0.50 | |

| Bio polish | 0.30 | |

| DBC | 1.00 | |

| Lubrica SB | 1.50 | |

| Gluber salt | 40.0 | |

| Remazol B Yellow 3GL | 1.156 | |

| Remazol Yellow RR | 0.3425 | |

| Remazol Blue RR | 0.003 | |

| Soda | 15.0 | |

| Acetic acid | 1.00 | |

| Dispercar EP | 0.50 | |

| Acetic acid | 0.20 | |

| CWS | 1.50 |

Production process sequence for 100% Cotton Fabric (Medium Shade):

Fabric loaded on the machine

Machine filled with water according to the requirement

All pretreatment Chemicals inject at 60° C

NaOH dozing for 10 minute at

Raise the temperature to 110° C

Run for 30 min

Cooling at 80° c

Rinse at 80° C

Run time 10 min

Cooling at 50° C

Drain the liquor

Machine filled with water according to the requirement

Acetic acid inject

Peroxide killer inject

pH check ( 4 to 4.5 ) ( If not ok )

Enzyme inject

Raise the temperature to 55° C

Run for 30 min

Sample cutting ( if ok)

Drain the liquor

Normal wash at 40C for 10 min

Drain the water

Levelling & Lubrica SB inject at 60 C

All salt inject at 60 c

Color dozing at 60C for 40 min

Run for 15 min

Soda dozing at 60C for 45 min

Run for 1 hr

If CMC is ok then drop the liquor

acid wash at 40 C for 10 min

Normal hot at 70c for 10 min

Fixing agent at 40C and run for 10 min

Normal wash

Softener inject at 40 C for 15 min

Wash and unload the material

Dark Shade:

M/C no : 07

Fabric type : Single Jersey

Color : Black

Special instruction: Enzyme wash

Yarn count : 30 s

Buyer : ITPS

Fabric GSM : 200

Fabric Weight : 850 Kg

M: L : 1 : 8

Recipe:

Name of the Chemicals g/l %

BLN 1.0

1000L 0.80

Lubrica SB 1.50

OKB 0.30

ASA 0.3

NaOH 3.0

H2O2 4.0

Acetic acid 1.0

WEZ 0.50

Bio polish 0.30

DBC 1.00

Lubrica SB 1.50

Common salt 50.0

Synozol Black HFGRP 6.8

Synozol Yellow HF4GL 2.2

Soda 20.0

Acetic acid 1.00

Dispercar EP 0.50

Acetic acid 0.20

CWS 1.50

Production process sequence for 100% Cotton Fabric (Dark Shade) :

Fabric loaded on the machine

Machine filled with water according to the requirement

All pretreatment Chemicals inject at 60° C

NaOH dozing for 10 minute at

Raise the temperature to 110° C

Run for 30 min

Cooling at 80° c

Rinse at 80° C

Run time 10 min

Cooling at 50° C

Drain the liquor

Machine filled with water according to the requirement

Acetic acid inject

Peroxide killer inject

pH check ( 4 to 4.5 ) ( If not ok )

Enzyme inject

Raise the temperature to 55° C

Run for 30 min

Sample cutting ( if ok)

Drain the liquor

Normal wash at 40C for 10 min

Drain the water

Levelling & Lubrica SB inject at 60 C

All salt inject at 60 c

Color dozing at 60C for 40 min

Run for 15 min

Soda dozing at 60C for 45 min

Run for 1 hr

If CMC is ok then drop the liquor

Acid wash at 40 C for 10 min

Normal hot at 70c for 10 min

Fixing agent at 40C and run for 10 min

Normal hot wash

Normal wash

Normal wash

Softener inject at 40 C for 15 min

Wash and unload the material

White Color :

M/C no : 06

Fabric type : Single Jersey

Color : White

Special instruction: Enzyme wash

Yarn count : 30 s

Buyer : ITPS

Fabric GSM : 200

Fabric Weight : 620 Kg

M: L : 1 : 8

Recipe:

Name of the Chemicals g/l %

BLN 1.0

1000L 0.80

Lubrica SB 1.50

OKB 0.30

ASA 0.3

NaOH 3.0

H2O2 4.0

Acetic acid 1.0

WEZ 0.50

Bio polish 0.30

Production process sequence for Polyester- Cotton Fabric (White color) :

Fabric loaded on the machine

Machine filled with water according to the requirement

All pretreatment Chemicals inject at 60° C

NaOH dozing for 10 minute at

Raise the temperature to 110° C

Run for 30 min if not ok

Then added OBA

If the sample is ok then

Cooling at 80° c

Rinse at 80° C

Run time 10 min

Cooling at 50° C

Drain the liquor

Machine filled with water according to the requirement

Acetic acid inject

Peroxide killer inject

pH check ( 4 to 4.5 ) ( If not ok )

Enzyme inject

Raise the temperature to 55° C

Run for 30 min

Sample cutting ( if ok)

Drain the liquor

Normal wash at 40⁰C for 10 min

Drain the water

Process flow chart of Turquoise color:

Fabric loaded on the machine

Machine filled with water according to the requirement

All pretreatment Chemicals inject at 60° C

NaOH dozing for 10 minute at

Raise the temperature to 110° C

Run for 30 min

Cooling at 80° c

Rinse at 80° C

Run time 10 min

Cooling at 50° C

Drain the liquor

Machine filled with water according to the requirement

Acetic acid inject

Peroxide killer inject

pH check ( 4.5 to 4.7) ( If not ok )

Enzyme inject

Raise the temperature to 55° C

Run for 30 min

Sample cutting ( if ok)

Drain the liquor

Normal wash at 40° C for 10 min

Drain the water

Levelling inject at 60° C

Color dozing at 60° C temperature for 40 min

Run for 10 min

Salt inject at 80° C temperature

Run time for 10 min

Cooling at 60° C

Soda dozing at 60° C for 35 min

Run for 10 min

If shade is match B/D wash

Soaping at 80° C for 10 min

Normal wash

Acid wash at 50° C for 15 min

Fixing Agent added at 40 ° C for 15 min

Normal wash

Softener added at 40° c for 10 min

Washing for 10 min

Unload the material

Process flow chart for soaping:

Machine filling with water

Raise the temperature to 60° C

Chemical dozing

Raise the heat to 95° C

Run for 10 min

Cooling at 70° C

Normal wash

Drain

DYEING PARAMETERS:

PH Levels for Different Stages of Cotton Dyeing:

1. Initial Bath pH 6.5~7.0.

2. Before Enzyme, bath pH 4.5~4.7.

3. After Enzyme pH 5.5~6.0.

4. Scouring & Bleaching, bath pH 10.0~10.5.

5. After Scouring & Bleaching, pH 8.5~9.0.

6. After Adding Dyes, pH 6.2~6.35.

7. After Addition of Salt, pH 7.5~8.0.

8. After Addition of Soda, pH 10.5~11.0.

9. Before Softener, bath pH 7.2~7.8.

10. After Softener Addition, bath pH 6.5~6.8.

pH Levels For Different Stages Of Polyester Dyeing :

1. Initial bath pH 6.5~7.0.

2. Scouring, bath pH 10.0~11.5.

3. After Scouring, bath pH 8.5~9.0.

4. After Addition of Colors, bath pH 4.2~4.3.

5. During Reduction Clearing, bath pH 10.5~11.5.

6. Before Softener, bath pH 6.3~6.8.

Common dyeing faults with their remedies:

1. Crease mark:

Causes:

– Poor opening of the fabric rope

– Shock cooling of synthetic material

– If pump pressure & reel speed is not equal

– Due to high speed m/c running

Remedies:

– maintaining proper reel sped & pump speed.

– Lower rate rising and cooling the temperature

– Reducing the m/c load

– Higher liquor ratio

2. Uneven dyeing:

Causes:

– Uneven pretreatment (uneven scouring & bleaching).

– Improper color dosing.

– Using dyes of high fixation property.

– Uneven heat-setting in case of synthetic fibers.

– Lack of control on dyeing m/c

Remedies:

– By ensuring even pretreatment.

– By ensuring even heat-setting in case of synthetic fibers.

– Proper dosing of dyes and chemicals.

– Proper controlling of dyeing m/c

3. Batch to Batch Shade variation:

Causes:

– Fluctuation of Temperature.

– Improper dosing time of dyes & chemicals.

– Batch to batch weight variation of dyes and chemicals.

– Dyes lot variation.

– Improper reel speed, pump speed, liquor ratio.

– Improper pretreatment.

Remedies:

– Use standard dyes and chemicals.

– Maintain the same liquor ratio.

– Follow the standard pretreatment procedure.

– Maintain the same dyeing cycle.

– Identical dyeing procedure should be followed for the same depth of the Shade.

– Make sure that the operators add the right bulk chemicals at the same time and temperature

in the process.

– The pH, hardness and sodium carbonate content of supply water should check daily.

4. Patchy dyeing effect:

Causes:

– Entanglement of fabric.

– Faulty injection of alkali.

– Improper addition of color.

– Due to hardness of water.

– Due to improper salt addition.

– Dye migration during intermediate dyeing.

– Uneven heat in the machine, etc.

Remedies:

– By ensuring proper pretreatment.

– Proper dosing of dyes and chemicals.

– Heat should be same throughout the dye liquor.

– Proper salt addition.

5. Roll to roll variation or Meter to Meter variation:

Causes:

– Poor migration property of dyes.

– Improper dyes solubility.

– Hardness of water.

– Faulty m/c speed, etc

Remedies:

– Use standard dyes and chemicals.

– Proper m/c speed.

– Use of soft water

6. Dye spot:

Causes:

– Improper Dissolving of dye particle in bath.

– Improper Dissolving of caustic soda particle in bath.

Remedies:

– By proper dissolving of dyes & chemicals

– By passing the dissolved dyestuff through a fine stainless steel mesh strainer, so that the . large un-dissolved particles are removed

7. Wrinkle mark:

Causes:

– Poor opening of the fabric rope

– Shock cooling of synthetic material

– High temperature entanglement of the fabric

Remedies:

– Maintaining proper reel sped & pump speed.

– Lower rate rising and cooling the temperature

– Higher liquor ratio

8. Softener Mark:

Causes:

– Improper mixing of the Softener.

– Improper running time of the fabric during application of softener.

– Entanglement of the fabric during application of softener

Remedies:

– Maintaining proper reel sped & pump speed.

– Proper Mixing of the softener before addition.

– Prevent the entanglement of the fabric during application of softener

Problem in Knitting

Knitting Fault : For these types of fault the Knitted Fabric will not be eligible Dyeing and Finishing

Major fault:

1. Pattra effect

2. Long needle break mark.

3. More star mark.

4. Frequent hole

5. More slub.

6. Wheel mark.

7. Sinker mark.

Minor fault:

1. Pattra for white color.

2. Slub for White color

3. Oil mark for colored Fabric

Chapter -7

Laboratory Facilities

Machineries of the dyeing lab: The following types of machineries are available in the RAHMAT KNIT-DYEING $ FINSHING LTD Dyeing Laboratory,

Machine available

• Data color.

• Auto dispenser.

• Light box.

• Dryer machine.

• Shrinkage tester .

• Rubbing tester machine

• Washing machine.

• GSM cutter.

• Sample cutter.

• Electric balance.

• pH tester.

• Grey scale.

Lab dip Preparation: Lab dip is prepared from the swatch supplied by the buyer. First of all the swatch is set into the Data Color and predicted the recipe and including this recipe another predicted recipe are also given. Following these recipe Lab Dip is prepared before it send to the bulk production.

Instrumental Color matching process:

Data Color flow chart:

Swatch supplied to the Data Color

Recipe predicted by the Data Color. Input database

History of the Lab

Initial recipe

Laboratory dyeing Recipe correction

Use L* , a*, b* to match. Not matched

OK

Production Dyeing. Production correction

Use L* , a*, b* to match. Not matched

OK

Finished

Function of Spectrophotometer:

1. Recipe prediction.

2. Color difference measurement.

3. Metamerism.

4. Pass /fail operation.

5. Reflectance curve.

6. Fastness rating.

7. Shade library.

Available Stock Solutions:

Red –0.01, 0.1%, 0.5%, 1.0%, 2.0% (very common)

Yellow – 0.01, .01, 0.1%, 0.5%, 1.0%, 2.0% (very common)

Blue – 0.1,0.1%, 0.5%, 1.0%, 2.0% (very common)

Preparation:

(1) To prepare 0.1% Stock solution, it is necessary to mix 0.1 g dye and 100 cc water.

(2) To prepare 0.5% Stock solution, 0.5 g dye stuff is mixed with 100 cc water..

(3) To prepare 10% Stock solution of Soda ash, 10 g Soda is mixed with 100 cc water.

Stock solution of Chemicals: Normally Salt solution are 15%,20% and Soda solution percentages are 5 %, 6% for using in the laboratory.

Pipet Measurement:

Sl No. Stock Soln Pipate (ml)

1 0.001-0.1 0.1

2 0.1-0.2 0.2

3 0.2-0.5 0.5

4 0.5-1 1

5 1-2 2

6 2-2.9 3/2.5

7 3 5

8 5 10

Dyes and Chemicals measuring formula in the Laboratory:

Sample weight X Shade %

Amount of Dye =

Dyes stock solution %

For example:

If Fabric weight = 5 gm

Shade % = 2%

Let Dye stock solution is 1.0%, then

5 X 2 X 100

Amount of Dye solution=

1 X100

=10 cc

Amount of Chemicals solution is calculated in the following way:

Fabric weight X Liquor ratio X Chemical amount

Amount of Chemicals solution =

1000 X Chemical stock solution%

Example:

If Fabric weight = 5 gm

Salt = 30 g/l, M: L= 1 :8

Let Chemical stock solution is 20.0%, then

5 X 8 X 30 X 100

Amount of Chemicals solution=

1000X 20

= 6 cc

Working Procedure:

All ingredients had been taken according to the recipe into the pot of sample dyeing machine. At a room temp or 450c the material had run 15-10 min then we mixed in here soda and then is started to rise the temperature at 1°C/ min. to get 60°C temperature. For performing the required dyeing temperature it took 60 min’s. The material had dyed at 60°C for 60 min’s. then the temperature was reduced at room temperature within in 10 mins. The fabric washed in cold water & then the material was washed in 1 gm/l soap solution (liquor ratio 1:20) at 80-90°C temperature for 3 min’s by hand(2-3Times). Then after rapidly cold washing the material was dried & preserved. Finally we go to our next step(inspection table).

Chapter -8

Quality Assurance System

Quality control: In this RAHMAT KNIT-DYEING $ FINSHING LTD laboratory all types of test are done by following the ISO test procedure. But sometime the test is also done by following the buyer recommendation.

List of Equipment:

1. Washing machine.

2. Rubbing fastness testing machine.

3. Light box.

4. Electric balance.

5. pH meter.

6. Shrinkage and Spiraled measurement instrument.

7. Grey scale.

8. Sewing machine.

Quality Assurance Procedure:

1. Online Quality Control.

2. Offline Quality Control.

Online test:

• GSM of the Fabric.

• Width of the Fabric

• Shade check.

• Visual appearance ( Enzyme performance)

Off line test: The offline tests are following types,

1. Physical test and

2. Chemical test.

Physical test:

• Finished fabric diameter.

• GSM of the fabric

• Color fastness to Rubbing

• Color fastness to Wash

• Shrinkage and Spiraled test.

Chemical test:

• Fibre burn out test.

• pH test.

Physical test:

Finished fabric diameter: Finished fabric diameter is an important factor for maintain the Quality of the fabric. This finished fabric dia is controlled by the Compacting machine.

GSM of the fabric: By the help of GSM cutter machine the fabric is cut. The sample is then weighted in the Electric balance, with the weight a constant number 100 is multiplied and finally we get the GSM of the Fabric.

Color fastness to Rubbing: The following test method is ISO 105 (X 12). The requirement of this test is following,

Sample size : (20 X 10) cm

No of rotation : 10

Figure diameter: 1.59 cm

Load : (9±0.5) N

Assessment: here two types of assessment is done one is Dry rubbing and another is Wet rubbing .According to the buyer requirement the result are supplied.

Color fastness to Wash: The following test method is ISO 105 C06. The requirement of this test is following,

Sample size : (10 X 4) cm

Multifibre size : (10x 4) cm

Time : 30 min

Temperature : 40° C

Machine RPM : 50

No of steel ball :10 pcs

Detergent : ECE detergent 4 g/l

Na perborate 1 g/l

Assessment: here two types of assessment is done one is Change scale and another is Staining scale .According to the buyer requirement the result are supplied.

Shrinkage and Spirality test: The Shrinkage and Spirality are measured in the following way,

Sample size : ( 50 X 50) cm

Template size : (50 X 50)

Inner side Template size: (35 X35 )cm

Procedure: The fabric is cut into square size. Then three side of the fabric is sewn and one side is open. Now the sample is ready to send in the machine.

The Spirality of the fabric is measured in the following procedure

Average distorted Length/ Width of the fabric

Spirality = X100

Average after wash Length/ Width of the fabric

The shrinkage percentage of the Fabric in the factory is measured with the help of a standard scale. But according to the calculation the formula is following,

Before wash Length/ Width – after wash Length/ Width

Shrinkage= X100

Before wash Length/ Width

Chemical test:

Fibre burn out test: This test is performed in case of P/C fabrics. 70% conc Sulphuric acid (H2SO4) is added according to the requirement of the sample and thus Cotton part of the sample is destroyed. Finally polyester part is rest.

pH test : To check the Fabric pH this test is performed. This test is performed in the following way. The requirement of this test is following,

Sample: 2 gm

Time : 16 hr

pH : ( 4 to 7.5 )

M: L : 1: 50

Remark: Quality control department is an important department in the Textile industry. Here the quality of the product is ensured. If they conform the quality of the product is ok then shipment will be allowed, otherwise it will not ready for the shipment.

Chapter -9

Chemical Management

MSDS (Material Safety Data Sheet) :

1. Salt / Electrolight:

Product name:

• Common Salt

• Gluber salt

Function: To penetrate the Dye molecule into the Fabric.

2. Sequestering agent:

Product name:

• Chemquest 1000 L

Function: To deactivate hardness from the water.

3. Anticreasing agent:

Product name:

• Lubrica SB

• Chemcrease

Function: To remove crease mark from the Fabric surface during Dyeing.

4. Enzyme Finishing agent:

Product name:

• CX Ultra

• Bio polish EC

Function: To remove hairy fibre from the Fabric surface.

5. Levelling agent:

Product name:

• Tricar- P

Function: Used for level Dyeing.

6. Detergent :

Product name:

• Foryl –BGL

• Cottoclarin BLN

Function: Used to remove soil, oil & other impurities from the Fabric.

7. Peroxide killer:

Product name:

• Rucorit WEZ

• Chem percat 555Y

Function: To remove peroxide from the fabric after bleaching.

8. Peroxide stabilizer:

Product name:

• Rucostab OKB

Function: To preserve the strength of peroxide.

9. Antifoaming agent :

Product name:

• Albaflow jet

• Rustol ASA

Function: To reduce the foam formation during Dyeing.

10. Soaping agent:

Product name:

• Dispercar EP

Function: To cleaning the Fabric surface.

11. Fixing agent:

Product name:

• Setafix WW

• Setafix R

• Albafix FRD

• Temofix FR

Function: To fix the Dye molecule with the fibre.

12. Color Softener:

Product name:

• Sapamine CWS

• Decosoft JCC

Function: Used to soft the Fabric.

13. White softener:

Product name:

• Belsoft 200

• Belsoft F EUK

• Kepasoft BD

14. Reducing :

Product name:

• Hydrosulphite

Function: Used to reduce the color from the dyed Fabric.

15. Optical Brightening Agent:

Product name:

• Skywhite BVB

• Uvitex 2B

• Uvitex BBT

• Blankophor BBU

Function: Used to the whiteness effect of the white fabric.

Chapter – 10

Waste Management system

Effluent Treatment Plan (ETP): After wet processing of the fabric there are huge amount of water is wasted. But this water is harmful for the environment. So it is not discharged to the environment directly. Finally this water is processed to reduce the toxicity. The ETP process is describing bellow:

There are following types of ETP plant is found:

1. Chemical ETP

2. Chemical with biological ETP

3. Biological ETP

4. Chemical with ECR (Electro Contaminant Removal ) ETP

Function of the Chemicals & individual section:

H2SO4 : To maintain the pH. It is automatically controlled.

Bar separation: It separate the large particals which is present in the liquor.

Equalization tank: Here all waste water is mixed with each other and this mixture is kept here for 4 to 6 hour.

Equalization Transfer Pump: Effluent is transfer to the next tank with the help of this pump.

High Rated Solid Contain Clarifier (HRSCC): Here high rated solid molecules are clarified.

Bio Tower Feed Tank ( BTFT ): Here partially discolored water is present.

Bio Tower Feed Pump ( BTFP): By this pump the effluent is sent to the Bio tower.

Bio Tower ( BT): Basically Bio Tower is a active carbon filter. Here the following chemicals are removed, total dissolved solid, heavy metal, SO4 ion, Cr, Co, Mg, Ca etc.

Lamella Clarifier ( LC): Here Bacteria are present. In this tank urea is supplied and this urea is eat by bacteria, finally bacteria eat the Lamella.

Sludge Thickener (ST) :This is prepared when Green vitriol is added in this tank. After sometime electrolytic polymer is added, finally sludge size is increase. This sludge is collected .

Chlorination tank (CT): This tank removes the bad odor present in the water.

Chapter -11

Maintenance

Maintenance: The act which is done to Keep the factory plan equipments machine tools etc. in an optimum working condition, minimize the break down of m/c’s to improve Productivity of existing m/c tools and avoid sinking of additional capacity and to Prolong the useful life of the factory plant & machinery is called Maintenance.

Objectives of Maintenance:

• To Keep the factory Plants, equipments, Machine tools in an optimum working condition.

• To ensure specified accuracy to product and time schedule of delivery to customer.

• To keep the downtime of Machines to the minimum thus to have control over the production Program.

• To keep the production cycle within the stipulated range.

Types of maintenance:

• Preventive maintenance.

• Corrective maintenance.

• Predictive maintenance.

Preventive Maintenance: Preventive Maintenance is a predetermined routine activity to ensure on tome inspection or checking of facilities to uncover conditions that may lead to production break downs or harmful depreciation.

Corrective Maintenance: In this case, repairs made after the equipment is out of order and it can not perform its normal functions. This maintenance is carried out when the machine is totally out of order.

Maintenance Tools & Equipments and their functions:

1. Combination tools (Spanner)

Function: Tightening & Loosening of Nuts & bolts

2. Socket Ratchet set

Function: Tightening of Nuts & bolts

3. Slide Range

Function: Tightening & Loosening of Nuts & bolts

4. Pliers

Function: Tightening & Loosening of nut & bolts.

5. Pipe thread cutting tools

Function: To cut the thread in pipe.

6. Bearing Puller

Function: To assist the opening of Bearing from shaft.

7. Pipe Wrange

Function: Tightening & Loosening of Pipe joint.

8. Pipe cutting tools

Function:For pipe cutting

9. Hole punch

Function: Punching the hole.

10. Divider

Function: For circle making on metal & wood

11. Easy opener

Function:To open the broken head bolt.

12. Heavy scissor

Function:Cutting of gasket & steel sheet.

13. Drill M/C & Drill bit

Function: For drilling the material.

14. Welding machine

Function: For welding and cutting.

15. File

Function: For smoothing the surface.

16. Hammer

Function: For beating the metal.

17. Hacksaw blade

Function: For metal cutting.

18. Hacksaw ( wood)

Function: For wood cutting

19. Grinding stone

Function: For smooth finishing.

Remarks: Maintenance is an important thing in any industry. In this company the authority always maintain the corrective maintenance except some Machine.

Chapter -12

Utility service

Utility facilities available: The following utility facilities are available in the ROBINTEX GROUP,

• Boiler

• Electricity Generator.

• Air compressor.

• Water Treatment Plant ( WTP)

Boiler: Boiler are used in the Dyeing industry for heating purpose.

Function:

• To generate steam.

• Supply the steam as per requirement of the machine.

Total number of Boiler in the are following,

10 ton capacity 2 pieces

1ton capacity 2 pieces

1.24 ton capacity 1 pieces

350 Kg capacity 2 pieces

The specification of the boiler:

1.

Boiler name :Shellemax

Model number :SM- 100B

Origin :India

Boiler type : Fire tube Boiler

Capacity : 10 ton

Number of tube : 190

Steam pressure : 8 bar

Gas pressure : 120 mbar

Air pressure : 280 mbar

Fuel : Natural gas

2. Boiler name : Energen.

Model number :SGCM

Serial number : 1000 B/1

Origin : India

Boiler type : Flue gas Boiler

Capacity : 1.24 ton

Steam pressure : 8 bar

Fuel : Flue gas

Electricity Generator: RAHMAT KNIT-DYEING & FINSHING LTD has its own electricity producing generator. Here we found two types of generator,

• Gas generator.

• Diesel generator.

Another types of electricity is used in the factory and this is PDB line.

The specifications of the generator are given bellow:

1. Machine name : Caterpiller

Machine type : Gas generator

Engine type : V type engine

Origin : U.S.A

Engine capacity : 1430 HP

Generator capacity : 1030 Kw/hr, 1288 KVA

Number of cylinder : 16

Gas pressure : 16 psi

2 . Machine name : Caterpiller

Machine type : Diesel generator

Engine type : V type engine

Origin : U.S.A

Model number : 275

Serial number : CAT 00008NS04929

Generator capacity : 220 Kw/hr, 250 KVA

Number of cylinder : 6

Rated voltage : 400/230

RPM : 1500

Air compressor: Air compressor is used in the industry where pressurized air is required. The pressurized air is required in the following section of the Dyeing industry, and it is also required in the Knitting section,

• Dyeing section.

• WTP section.

• Knitting section.

• Finishing section.

• Garments section.

The specification of the air compressor is given bellow:

1.

Machine name : KAESER

Model number : ASD47

Maximum air pressure: 11.0 bar

Origin : German

Serial number : 1010/09/11

RPM : 3000

2.

Machine name : Atlas copco

Model number : GA55

Maximum air pressure: 10.0 bar

Origin : Finland

RPM : 3000

Water treatment plant: Water treatment plant is essential for dyeing industry. Because the raw water contain metal ion, cupper, iron and etc. it causes problem during dyeing. So water has to purified. There are many types of water treatment process. In this industry Soda lime and Base exchange process are followed.

Types of water treatment plant:

• Soda lime process.

• Base exchange process. .

• Demineralization process.

• Aeration process.

Here Base exchange process are described: At first deep water is collected in the main store tank. By the help of feed pump it is transferred into the another tank, this tank function is to remove odor. Then this water is followed three steps of another tank. Finally it entered into the resin tank with the help of this tank, water is free from the heavy metal ion and other impurities.

Cost of different utility:

Gas generator per unit cost =3.96 Tk

Diesel generator per unit cost =11.2 Tk

PDB cost = approximately 7.0 tk

Cost of gas= 4.18 Tk per cubic meter

Remark: For continuous production in the dyeing industry, utility section have to maintain strictly. Otherwise production will be hampered.

Chapter -13

Cost analysis

Costing of the product: The costing of the product has not been supplied due to the company’s secret act.

Chapter -14

Marketing Activities

Buyer of the product:

1. H &M.

2. ITPS.

3. Cello.

4. Puma.

5. Slanzeger

Brand importing country:

• Germany

• Switzerland

• Etc

Buyers’ complain : All the buyer of this industry always follow the working condition of the industry. If they satisfy that the company is fully maintain the rules and regulation strictly, they accept the production and ensure their faith for further relationship.

Remark: The company always follow the satisfaction. Buyer satisfaction is their first priority. Day by day they are getting more order by following this marketing strategy.

Conclusion

Limitations of the report:

Because of the company’s secret act costing & marketing activities have not properly supplied.

Organogram of the administration has not supplied due to the time limitation.

Some topics are not included which was not collected due to time limitation.

Conclusion: Now a dyes textile field becomes very competitive and the buyer wants 100% export quality product. For this reason it is very important to about the textile sector. To produce the quality product the Textile Engineers must need vast knowledge. During my training period I had learned about the production control system. How to improve the RFT of the Dyeing factory. In my training period I have learnt about the different parts of the machine and their function. In this time I have also get an idea about the responsibilities of different department of the factory. Therefore I think this practical knowledge will help me in future.