Introduction:

Bangladesh is an energy hungry country. Power infrastructure of Bangladesh is small and insufficient but the demand is rapidly increasing. The per capita power consumption in Bangladesh is about 136kwh which is one of the lowest in the world but for huge population density our power sector is in enormous pressure. In Bangladesh, electricity is the major source of power and most of the economical activities depends on electricity.

Generation of electricity

Total electric power generation (installed) capacity of Bangladesh is 5823MW [BPDP, June 2010] and only three-fourth of which is considered to be available. The present [Feb, 2011] effective power generation capacity per day is about 4000 MW and the demand is 5000MW. Only 40% of our total population has the access to electricity and in rural areas it is less than that .

Bangladesh has small reserves of oil and coal, but potentially very large natural gas resources that’s why, most of the generation plant used natural gas as fuel. Some coal, diesel, furnace oil is also used in production of electric power. About 87% of our total electric power is produced by natural gas, 5.75 % by furnace oil, 4.29 % by coal, 3.19 % by diesel and 3.95 % is produced from hydro electric plant.

Electricity distribution and consumption

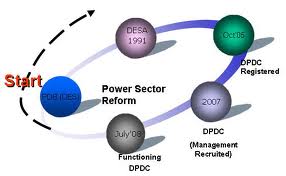

In Bangladesh, electricity distribution system in controlled by national grid. Total electric power, generated from the power plants is first supplied to the national grid then to the hole counrty through national grid. The Padma-Jamuna-Meghna river divides power distribution sytem into two zones, East and West. The East contains nearly all of the country’s electric generating capacity, while the West, with almost no natural resources, must import power from the East. Electricity interconnection from the East to the West was accomplished in 1982 by a new, 230-kilovolt (kV) power transmission line. The vast majority of Bangladesh’s electricity consumption takes place in the East, with the entire region west of the Jamuna River accounting for only 22% of the total. There are many organizations to distribute electric power in hole country. Dhaka electric supply authority (desa), Dhaka electric supply company (desco), dhaka power development corporation (DPDC), rural electrification board (REB), west zone power development company limited (WZPDCL) etc.

In last few years power consumption in bangladesh is increased in such a high rate that, inspite of increasing the power generation in a considerable amount , our power system doesn’t meet the goal and still we have a large amount of power shortage.

key problems in power sector

Load shedding and voltage variation

The state-owned Bangladesh Power Development Board (BPDB), which controls nearly three-fourths of the total generation capacity in Bangladesh, has resorted to load shedding as a means to reconcile demand to the available capacity. Load shedding is a significant constraint on growth of the economy.

Operating Inefficiency

The power sector does not fare well in terms of operating efficiency. For example, Bangladesh requires considerably more employees per customer served than is the case in many countries.

System loss

System loss occurs both for technical reasons and for reasons of inefficiency and corruption in administration. Exact figures of loss are unknown but, at approximately 30 per cent, the net country-wide system loss is probably among the highest in the developing world. The losses incurred differ dramatically across the various utilities.

Unadjusted tariff structures and ineffective billing procedures

Many countries have been unable to establish tariff structures and billing procedures that enable the power sector to be financially self-supporting. The resulting losses require subsidies from government or donor agencies that divert revenue away from other important programmes,such as education and public health. This problem has afflicted the Bangladesh power sector entities to varying degrees.

Recommendations

Bangladesh is a developing country and most serious challenges we faces is power crisis. What ever we forecast for demand but our calculation failed because if you produce right now 7000 megawatt, it will fulfill with in a very short time because of many development and industries are waiting for power. If power is available, we will see many new projects, industries will consume immediately.

In electricity, when we save power it means we produce power. If somebody save 100 watt, another user can use that power. Therefore energy efficiency is essential in every electric product. All the develop world even India also have energy efficiency authority to motivate and regulating energy efficiency policy.

Now, let’s see in which sector we can reduce use of energy and some policy to motivate the people.

Industrial Sector

Major energy use in industrial sector and there are inductive and non inductive load. In our country, there are no major rules or not applied properly the rules for machine use. Like many industry using motor and sometimes those motor are not efficient at all and may be it will be recondition or old enough to be an efficient motor. Most of the inductive load do not have soft starter. Even in general use of water pump, there are no standard efficient level for selecting pump. Therefore people using 2500 tk water pump and that same 1 hp pump, in good branded one will be 7500 or higher. But people choose low price one which will destroy power and less efficient.

Air condition

Now on days, we are used to use of these products. It is inductive load and consumed good amount of energy. Nobody cares to reduce the temp level or efficient products. Recently, at the same price, many manufacture offering 50% less power but same BTU because they are using DC motor. Therefore high tax, high electricity unit price where higher then 3-5 kilo residential load needed. But it may not be possible due to political and public emotion purpose. But still there are no substitutes to make energy expensive then people will careful to use of energy.

Lighting purpose

We came to new energy saving age and using cfl bulb or tube. It will save energy sure but it cause heavy damage in environmental. Every cfl contain mercury and emit UV. UV is harmful for our skin and mercury is highly radioactive poison. When any bulb damage in our room, we have to keep vacant that room and open door, windows because of mercury vapor. After that we send it outside or sale. If it is goes to river, soil it will damage the water and its poison circle will start. It affect drinking water, fish and we take water or fish and cause cancer, unborn child defect, etc. Some tube light THD level also too high which decrease gird performance. we can use LED light in this purpose. It is environmental friendly, long life (50000 Hrs where cfl is 3000 to 5000 hrs), very less energy consume even one third comparing cfl. As it is still expensive, we can use certified cfl and rules and regulation for recycling cfl. Another thing is still now; customs do not have HS code or tax structure for led light, bulb or tube. Led light must have duty/ tax free access.

BTS for mobile operator

Bangladesh has rapidly expanding mobile uses and according to that base transmission station also need. Now, 25000 over BTS running and more 7000 or more coming within 2 years. For mobile company, energy unit rate must have different category (high). Every BTS they use 2 pc 1 ton air conditioner which run round the clock. Now, if we calculate everyday 18 hrs air condition running this means 32.4 kilo only air condition. 32.4 times 25000 = 810000 kilo everyday 810 megawatt everyday.

Future plan

In Bangladesh ,crisis in power sector becomes one of the major problems .some recent steps and a strong and clear forecasting is needed to overcome that problems .power sector is always been one of the major priority for Bangladesh government . To overcome the problems, a large and clear future plan is been taken by Bangladesh government.

Bangladesh government will increase power generation to reach their goal of ‘load shedding free Bangladesh ” , for that a large number of power new plant will be installed in next 5 years.

Power plant in Sirajgonj

Prime Minister of Bangladesh Sheikh Hasina recently (4th april,2011) laid foundation stone of 150 megawatt peaking power plant at Saidabad in the district. Hasina also inaugurated expansion works of the Saidabad-Enayetpur road and reopened the much-expected Sirajganj National Jute Mills previously known as Qaumi Jute Mills.

Chittagong power to get Canadian help

A Canadian company has expressed its interest in generating electricity from the domestic waste produced by the Chittagong city people every day. CEO of Canadian Company Technology Not Theory (TNT) Steve Smith expressed the interest to the Mayor of CCC in meeting with the mayor recently. The project is fully environment friendly and pollution free, Smith pointed.

Power Grid Company installing substation

The Power Grid Company of Bangladesh recently signed an agreement with German company Siemens to install a substation that would link about 30 kilometers grid interconnection between Bangladesh and India to import 500MW electricity from 2012.

BGMEA to set up power plant

Bangladesh Garment Manufacturers and Exporters Association (BGMEA), apex body of the readymade garment (RMG) industry, will shortly begin a technical assessment on setting up small, area-based power plants. The BGMEA move came in response to Prime Minister (PM) Sheikh Hasina’s call recently to set up such power plants to meet industry demand.

North West power generation company to install 810 MW power plant

North-West Power Generation Company (NWPGCO), a newly formed state-owned power company, is set to install 810 MW power project in the northwestern part of the country to address nagging power crisis of the area.

Bangladesh and India power transmission deal

Bangladesh and India signed a power transmission agreement for electricity to be imported to energy-starved Bangladesh.

Initially, 250 megawatts of power would be available to Bangladesh from India, with transmission to start in 2012.

Under the deal, state-owned Power Grid Corporation of India Ltd. will invest and construct 50 miles of transmission line, which it will own, operate and maintain. PGCIL will recover the construction costs under a fixed rate over 35 years.

While the agreement is limited to importing 500 megawatts of electricity from India, state-owned Bangladesh Power Development Board Chairman Alamgir Kabir said that more interconnections might be built in the future with Nepal, Bhutan and Myanmar to ensure greater energy security

Bangladesh and Russia deal

In May 2011, Bangladesh and Russia signed a framework agreement for Bangladesh’s first nuclear plant, expected to produce at least 2,000 megawatts of electricity by 2020. Bangladesh aims to have nuclear energy account for 10 percent of its total power generation by that time.

Government to set up coal based power plant

According to Power System Master Plan (PSMP) the government has planned to set up eight new power plants with 4,000MW capacity by the year 2015. The government has primarily identified 13 places to install coal based power plants and now trying to install four plants at Khulna, Mongla, Meghnaghat and Chittagong areas, Taking into consideration the fast-growing demand of power consumption amid scanty supply, the PSMP has also taken up a mega-plan for producing about 20500MW additional electricity in 20 years from 2005 to 2025 by setting up 30 new plants. Bangladesh government needs US dollar six billion to implement coal power projects to meet the increased demand of electricity in the country. Of the plants, eight or more will be installed in the country’s north and northeastern regions where demand for electricity is increasing at a galloping rate of seven percent, in order to achieve this goal the development of Barapukuria and Phulbari should be more intensive.

SOURCE OF ENERGY

Natural Gas

Natural gas is a major source of electricity generation through the use of gas turbines and steam turbines. Most grid peaking power plants and some off-grid engine-generators use natural gas. Natural gas burns more cleanly than other fuels, such as oil and coal, and produces less carbon dioxide per unit of energy released. For an equivalent amount of heat, burning natural gas produces about 30% less carbon-dioxide than burning petroleum and about 45% less than burning coal.

In Bangladesh natural gas is most important indigenous source of energy that accounts for 75% of the commercial energy of the country. About 89% of the electricity generated in the country comes from gas fired power plants. Installed capacity of Electricity generation by gas is steam-2638 MW (45.31%), Gas turbines-1466 MW (25.18%), combined cycle-1263 MW (21.69%). So far in Bangladesh 23 gas fields have been discovered with the rate of success ratio is 3.1:1 of which two of the gas fields are located in offshore area. Gas is produced from 17 gas fields (79 gas wells). To reduce the dependency on natural gas, alternative energy resource must be explored. Average daily gas production capacity is about 2000 mmcfd of which International Oil Companies (IOC) produce 1040 mmcfd and State Owned Companies (SOC) produce 960 mmcfd. At present the daily approximate projected gas demand throughout the country is 2500 MMCFD. The demand is increasing day by day. Energy and Mineral Resources Division (EMRD) has already undertaken an array of short, medium, fast track and long term plans to increase gas production to overcome prevailing gas shortage. After completion of these plans production capacity is expected to increase to about 2353 MMCFD gas by December 2015. To increase the gas production more programs will be taken in near future.

Oil

Oil is another source of electricity generation. Bangladesh is not a oil enriched country. Diesel, Furnace oil (HFO) are generally used in Bangladesh to produce electricity. Here 226 MW (3.87%) electricity generates from Diesel. To meet the total demand of commercial energy, Bangladesh imports annually about 1.3 million metric Tons of crude oil. In addition to this, another 2.7 million metric Tons (approx) of refined petroleum products per annum is imported. Condensate is mixed with crude oil. Major consumer of liquid fuel is transport sector followed by agriculture, industry and commercial sector which is mostly met by imported liquid fuel. Eastern Refinery Limited (ERL), a subsidiary company of Bangladesh Petroleum Corporation (BPC), is capable of processing 1.3 million metric Tons of crude oil per year.

Oil was tested in two of the gas fields (Sylhet and Kailashtila). Crude oil, the liquid form of hydrocarbon, has been discovered in commercial quantity only in the Haripur oil field in Sylhet. The oil field has an estimated in-place oil reserve of about 10 million barrels, with a recoverable reserve of about 6 million barrels. The oil field produced 0.56 million barrels of oil in six years. Khulna Power Company Limited is one of the main oil based power station of Bangladesh. Furnace oil is its main fuel.

Renewable Energy

Renewable energy is the energy which comes from natural resources such as sunlight, wind, rain, tides, water, and geothermal heat, which are renewable (naturally replenished). In 2008, about 19% of global final energy consumption came from renewable, with 13% coming from traditional Biomass, which is mainly used for heating, and 3.2% from hydroelectricity. New renewable (small hydro, modern biomass, wind, solar, geothermal, and bio fuels) accounted for another 2.7% and are growing very rapidly. The share of renewable in electricity generation is around 18%, with 15% of global electricity coming from hydroelectricity and 3% from new renewable.

Hydroelectricity

Karnafuli Hydro Power Station the only hydropower plant in the country is located at kaptai, about 50 km from the port city of chittagong. This plant was constructed in 1962 as part of the ‘Karnafuli Multipurpose Project’, and is one of the biggest water resources development project of Bangladesh. After being commissioned in 1962, the plant could feed the national grid with 80 MW of electricity. In later years, the generation capacity was increased in two phases to a total of 230 MW which is 3.95% of total generated electricity. The plant not only plays an important role in meeting the power demand of the country but is also vital as a flood management installation for the areas downstream.

In future hydroelectricity will be a probable sector of power generation of Bangladesh. Possibility of installing mini and micro level hydro-electric power plant in the hilly areas of Bangladesh would be explored.

Solar Energy

Solar energy is the energy derived from the sun through the form of solar radiation. Potential of solar energy is good in Bangladesh. Bangladesh is a poor country and it’s a huge cost to established a power plant. Consequently, the only option that is open to Bangladesh at the moment is renewable energy such as solar and hydro-electric. Particularly solar energy is sufficiently abundant in Bangladesh and can fruitfully be harnessed. But due to its higher cost of equipment it has to go a long way to become commercially viable. However, in remote areas of Bangladesh it is gradually becoming popular and government has undertaken lot of scheme to subsidize on it. Presently there are about 2, 64,000 solar panels installed throughout the country.

Now, more than 3 lakh houses (.3m) of 465 upazilla of all the districts and 16 islands are getting the light of solar energy. The beneficiaries of this system are about 30 lacks (3m). 44 megawatt electricity is produced everyday from the solar projects in Bangladesh. In future Bangladesh Government wants to produce 20% of electricity from the solar energy.

Bio-Gas

Biogas may be the most promising renewable energy resource. Presently there are about 50,000 households and village-level biogas plants in place throughout the country. There is a huge potential for expansion in rural areas.

There is prospect of producing 1,000MW electricity from Biogas and if the opportunity is utilized the growing shortage of electricity could be solved in this power-starved country. The government agency Infrastructure Development Company Limited sources said Bangladesh has 215,000 poultry farms and 15,000 cattle farms. Establishing biogas plants in these farms, electricity could be generated. So far 35,000 biogas plants have been established across the country and these plants are producing gas, which is being used for cooking purposes in the rural areas. At present 33 lack squire feet biogas is being produced in the country daily. The Government agency said they got eight core tons of cow dung in 2004.With this cow dung, 30 lack biogas plants could be run. Government has a target to establishing 60,000 biogas plants by 2012.

Wind Power

Wind power harnesses the power of the wind to propel the blades of wind turbines. 31 At the end of 2009, worldwide wind farm capacity was 157,900 MW, representing an increase of percent during the year. Germany, Spain, Denmark, Portugal, United States are leading wind power producer country.

Bangladesh generates a very small amount of electricity from this sector. Windmills are with capacity of 2 MW in operation in the coastal area of Bangladesh. The possibly of this type of power generation is low.

Nuclear Energy

Nuclear power station use nuclear fission to generate energy by the reaction of uranium-235 inside a nuclear reactor. Now a day it’s one of the major sources of electricity. At present in Bangladesh electricity generates from nuclear energy is 0%. Recently we signed an agreement with Russia to install our first nuclear plant at Rooppur in Pabna. The construction cost is initially being put at between US$1.5 billion and $2 billion in the final agreement The Rooppur nuclear power plant (RNPP) will eventually generate around 2,000 megawatts (MW) of electricity, with each of two proposed reactors having a capacity to generate 1,000 MW.

Coal as a source of energy

Coal is a valuable and plentiful natural global resource. Coal, a fossil fuel, is the largest source of energy for the generation of electricity, worldwide. Coal plays a vital role in electricity generation worldwide. Coal-fired power plants currently fuel 41% of global electricity.

Besides natural gas, Bangladesh has significant coal reserve. Coal reserves of about 3.3 billion tons comprising 5 deposits at depths of 118-1158 meters have been discovered so far in the north-western part of Bangladesh. The name of these deposits are-Barapukuria, Phulbari and Dighipara coal field in Dinajpur district, Khalashpir in Rangpur district and Jamalganj in Joypurhat district. Out of which 4 deposits (118-509 meters) are extractable at present. As an alternative fuel to natural gas, coal can be extensively used. The depth of Jamalganj coal deposit is 640-1158 meter with 1053 Million Tones in-situ coal reserve where production may not be viable by present day’s technology due to the depth of the deposits. Possibilities of extraction of Coal Bed Methane (CBM) need to be explored from this coal deposits. Government is actively reviewing law to be applicable for Exploration and Production of Coal Bed Methane. So far, only Barapukuria coal field is under production. Dinajpur Barapukuria coal fired power plant is our first coal based power plant which capacity is 250MW. Then some small power plant was made. Bangladesh has a bright future in coal based power generation if we remove the obstacle of this sector.

SOURCE OF COAL IN BANGLADESH

Coal fields of Bangladesh

Bangladesh is sleeping on coal mine bed located in the northern districts of Rangpur and Dinajpur, while facing a mounting energy crisis and relies on natural gas as the main source of energy, which is depleting at geometrical progression. In contrast, Bangladesh has proven reserve of 3.0 billion tonnes of low sulphur, low ash, high caloric value bituminous coal in five discovered coal mines – Phulbari, Barapukuria, Jamalganj, Dighipara and Khalsapir.

Bangladesh has 15 tcf (trillion cubic feet) of proven reserve of natural gas; the remaining 6 tcf reserve of natural gas may run out by 2015, if no discovery is made soon. As against this, the coal reserves in five fields of Bangladesh are estimated at 3.0 billion tonnes equivalent to 67 tcf of gas, which can conveniently serve the energy needs of Bangladesh for 50 years.

The depth of the discovered fields ranges between 119 – 506 metres and 150 – 240 metres in Barapukuria and Phulbari respectively. The depth of the largest field at Jamalganj ranges from 900 – 1000 metres. The area covered by coal fields is rather limited and is about 70 – 80 square kilometres. A total of 1.73 million tonnes of coal has been extracted by underground method from Barapukuria up to December 2008. The present value of coal per tonne in international market is for steam coal US$ 65-115, coking coal US$ 250, metallurgic coke coal US$ 525. The total value of coal will be more than US$ 500 billion.

Barapukuria Coal Field

The Barapukuria coalfield is located at the Parbatipur Upazila of Dinajpur district, at a distance of about 50 km southeast of Dinajpur town. The coalfield has a proved area of about 5.25sq km. The estimated resource of the coalfield is 390 MT.

The government decided to establish an underground coal mine at Barapukuria. In 1993, the government entered into a contract with the Chinese government for technical and financial assistances for establishing the mine. The mine construction by the Chinese contractor started in 1996 and was originally scheduled to be completed by 2001. But this was delayed and finally commercial production started from September 2005.

However, the underground mining operation in Barapukuria has been facing many difficulties from the beginning of its development stage. In 1998, a sudden water inrush flooded the mine and forced to suspend mine development works for two years. The revised mine design reduced both mineable reserve and mine life. In fact, the existing geologic setup: the thick overlying water bearing Upper Dupi Tila sequence, high jointed thick coal seam (36m) with numerous faults and joints made the situation difficult for smooth economic operation of the mine. The unfavorable underground mining environment with high temperature, very high humidity, and unidentified sources of hot water, spontaneous combustion and lethal gas emission made the situation dangerous and unhygienic for the mine workers. An incident of spontaneous combustion and emission of poisonous carbon monoxide gas led to suspend operation and sealing off a mining face with one of its longwall systems.

Phulbari Coal Field

The Phulbari coalfield was discovered in 1997 by BHP Minerals. The Phulbari coalfield is located about 10 km south of the Barapukuria coal field and in the vicinity of Phulbari township. The coalfield is conveniently located close to the new dual gauge rail line.

Subsequent to the discovery of Phulbari coalfield, BHP Minerals decided to withdraw from Bangladesh and transferred its Contract and existing licenses to another mining company Asia Energy Corporation (Bangladesh) Pty Ltd with the approval of the Government. In this regard, an Assignment Agreement was signed on 11 February 1998. The pre feasibility study carried out in 2000 confirmed the economic viability of large scale open pit mine in Phulbari Basin. Asia Energy had undertaken a detailed feasibility study including extensive geological, hydro geological, environmental and social studies during the period 2004-05 and established an internationally accepted (JORC Standard) resource of 572 Mt of high quality thermal and metallurgical coal.

The mining area in the Phulbari Basin covers an area of eight kilometers (north-south) by three kilometers (east-west) with coal seam(s) varying between 15-70 meters thick at some 150-270 meters beneath the surface, with average combined thickness of 38 meters. The Phulbari coal is high volatile bituminous coal. It has low ash (average 15%) and low sulfur content (<1%) and therefore suitable for both power generation and for producing semi-soft coking coal.

Asia Energy submitted Scheme of Development on October 2005 to the Government with a plan to develop the Phulbari coal deposit by the open cut mining method. In 5 years three governments failed to either approve the scheme or reject it with technical justifications. Coal resources of Phulbari remains unexplored.

The mine is estimated to produce 15 million tonnes of coal per year over 35 years of mine life. Asia Energy has also submitted proposal to setup up to 1000 MW mine mouth coal-fired power plant based on Phulbari coal. In addition to coal, the open pit mining method will allow economic extraction of other co-products like kaolin, clay, glass sand rock and aggregate, which are in high demand.

Jamalganj Coal Field

The Jamalganj coalfield is located in Joypurhat district in the vicinity of Jamalganj town and to the west of the north-south broad-gauge railway line. The coalfield was discovered in 1962 by the Geological Survey (of the then Pakistan) under the UN sponsored coal exploration program. Under the program 10 wells were drilled in the Jamaganj-Paharpur area of Joypurhat district. Coal seams were encountered in 9 wells within depth range of 640 to 1158 meter below the surface in Permian Gondwana rocks. The 9 bore holes that penetrated the coal seams are spread over an area having a maximum east-west distance of 12.5 km and a north-south distance of 4.8 km. The coal field has an estimated resource of 1053 Mt bituminous coal.

Following the discovery of the coalfield, several international consultants, were invited to conduct mine feasibility study. These include Fried Krupp Rohstoff (1966), Polwell Daffryn Technical Services (1969) and Robertson Research International (1976). Although rated technically feasible, the economic feasibility of mining Jamalganj coal could not be shown because of the unfavorable depth of coal seams. Eventually, the idea of mining coal from Jamalganj field was abandoned when a large coal deposit was discovered at much shallower depth of about 120 meter below the surface at Barapukuria basin in Dinajpur district. However, developing coal bed methane (CBM) in the Jamalganj coalfield has since been considered a potentially viable option.

Khalashpir Coal Field

Khalashpir coalfield is located in Pirganj Upazila of Rangpur district, about 13 km west of Pirganj town. Khalashpir coalfield was discovered in 1989 by the Geological Survey of Bangladesh. The coalfield was delineated and defined on the basis of the four drill holes done during 1989-90. The coal was encountered at depths ranging from 257 to 482 meter below the surface in a Gondwana basin. Occurrence of coal has been proved in an area of about 2.52 sq km and a further extension of the basin is estimated. The Khalashpir coalfield has an estimated resource varying from 143-450 Mt.

4.1.5 Dighipara Coal Field

Dighipara coalfield is located in Dighupara Upazila of Rangpur district, Dighipara coalfield was discovered in 1995 by the Geological Survey of Bangladesh. The coalfield was delineated and defined on the basis of the five drill holes. The coal was encountered at depths is 327meter below the surface. The Dighipara coalfield has an estimated resource of 200 Mt.

Coal mining methods

However, we failed to explore and exploit the natural resources to utilize these for economic development. We have miserably failed to cope up with the increasing energy demand of the country. We have age-old mining policy, mining act and mining regulations. We do not have any exploration and utilization strategy of gas reserve. We are yet to have a coal policy finalized. The Bureau of Mineral Development issued a license to BHP(Broken Hill Proprietary Company), Australia in 1994 for exploration of Phulbari Mine. The license was transferred to Asia Energy in 1997. Bangladesh media quoting responsible sources stated that Asia Energy is yet to obtain mining license. However, the mining could not proceed due to alleged lack of transparency in award of the license and unrest in the area triggered by a motivated group of left leaning intellectuals. The agitations lead to death of 6 protesters in police and paramilitary troops firing.Coal mining at Phulbari and other coal fields now hinges on the Coal Policy under consideration of the government. The Coal Policy is pending for quite some time due to disagreements on some issues, namely,

(a) Open pit versus underground mining

(b) Social environmental impact management

(c) Royalty etc. Government engaged committee having line professionals

Selection of mining methods depend on several things – geology of mine area, terrain condition, topography, soil condition and nature, depth, thickness and nature of coal seam, surface and subsurface soil condition.

One of the major challenges the energy sector is facing is to find out ways how to economically exploit its substantial high quality coal reserve .The predominantly mono fuel –Natural Gas dependent power generation is in limbo. The proven gas resource is widely believed to be exhausted in not too distant future. For confusion and panic set in by inexperienced ill motivated theoreticians and absence of strong political commitment government could not take decision of appropriate mining strategy to economically exploit coal resource. The deficit is widening. The ensuing summer will witness massive load shedding.

The just installed democratic government will face serious embarrassment for failures of incompetent last political and immediately past Care Taker Government. Of the 5 discovered ca coal mines the Jamalgonj coal is at greater depth which cannot be mined in traditional mining methods. Coal at Khalaspeer and Dighipara are also at relatively greater depth. Barapukuria and Phulbari coal are at relative shallower depth. The geology makes these ideal for open pit surface mining which is in practice in the following countries now.

Bangladesh which has limited capacity to purchase petroleum products from volatile world oil market cannot continue to keep its fortune buried underground forever. It cannot also remain confused triggered from myths and ill motivated propaganda of a vested group. The disadvantage is most of our innocent people as well as policy makers do not have much knowledge of mining. There is no scope of learning mining technology in Bangladesh also. During Pakistan days sons of well to do persons who could not get admissions in Ahshanullah Engineering College used to go to Lahore to study mining. This group of mining engineers worked in Gas sector in absence of mining activities in Bangladesh. They could neither become good miners nor good gas engineers. Rather for their control other professionals got frustrated and many left gas sectors. Many mining engineers created controversy in Gas Sector also. There were few outstanding mining engineers as well. But no all of them retired. But unfortunately none of them were included in drafting coal policy.

Bangladesh let a Chinese company start underground mining at Barapukuria. Many mining experts felt the existing geology can never make underground mining technically viable or economically feasible there. Still a vested group of BNP government from 1991-96 allowed to start Barapukuria mining under suppliers credit. Experts now feel that there were several juggleries in the project approval process. It now appears that proper risk assessments of Bapaukuria mining were not done. The possible and probable subsidence impacts were not anticipated and no actions were foreseen to address those impacts. Now after a more that one and a half decade of trouble tone mining with several major set backs at various stage mine subsidence impacts are now visible which may puts future of mining uncertain.

BHP Billiton, the leading Mining Company of the world was given mining lease at Phulabri where very thick seam bituminous coal is lying at shallow depth. At some stage of survey and assessment it transferred lease to Asia Energy Corporation. (AEC) UK.AEC carried out extensive survey, carried out some exploratory drillings, completed extensive Environment Impact Assessment studies. Then it submitted a comprehensive study to Government of Bangladesh in January 2005 after meeting all the contractual requirements. The development plan included surface mining methods. It included proper relocation and rehabilitation plan of the affected people. Bangladesh was due to approve to reject the development plan within the contractual time frame.

He engaged a so called Energy Expert to review the Phulbari mining matters. This gentleman stepped out of his assigned responsibility and agitated the people of Phulbari over AEC proposed open pit mining.BNP government should have done community consultations to pacify the situation. But a very arrogant Mahmud let situation go out of control .The local agitation led to unfortunate situation when some innocent misguided local people were killed.

The local situation was to be controlled by signing a compromise agreement by Mayor Rajshahi and MP. This irrelevant piece of paper was signed with a legally unrecognizable organisation. Now based on this the agitators are demanding to scrap AEC contract , banning open pit mining etc, etc & etc. Any sensible person will realize that such an agreement has no legal bearing in dealing with a contract signed between a sovereign government and an international company.

Any contract includes a termination clause. It requires one party to establish default of the other party with evidences. It also requires the party notifying default of the other party to give them to defend its position. If Bangladesh ventures to terminate the AEC contract then this will obviously go to arbitration. Bangladesh will invariably loose and will have to pay huge compensation.

Open pit mining

Open pit mining as defined in open encyclopaedia states, “Open pit mining, also known as opencast mining, open –cut mining, and strip mining, refers to a method of extracting rock or minerals from the earth by their removal from an open pit or borrow. Open –pit mines are used when deposits of commercially useful minerals or rock are found near the surfaces, that is where the overburden (surface material covering the valuable deposit) is relatively thin or the material of interest is structurally unsuitable for tunneling .For minerals that occur deep below the surface –where overburden is thick or minerals occurs as veins in hard rock – underground mining methods extract the valuable material.

Open pit mines are typically enlarged until either the mineral resources are exhausted, or an increasing ratio of overburden to ore makes further mining uneconomic. When this occurs, the exhausted mines are sometimes converted to landfills for disposal of solid wastes. However some form of water control is usually required to keep the mine pit from becoming a lake.

Open Cut mines are dug on benches, which describe vertical levels of the hole. These benches are usually on four meter to sixty meter intervals, depending on the size of the machinery that is being used. Many quarries do not use benches, as they are usually shallow.

Most walls of the pit are generally dug on an angle less than vertical, to prevent and minimize damage and danger from rock falls. This depends on how weathered the rocks are, and the type of rock, and also how many structural weaknesses occur within the rocks, such as a fault, shears, joints or foliations.

The walls are stepped. The inclined section of the wall is known as the batter, and the flat part of the step is known as the bench or perm. The steps in the walls help prevent rock falls continuing down the entire face of the wall. In some instances additional ground support is required and rock bolts, cable bolts and concrete are used. De-watering bores may be used to relieve water pressure by drilling horizontally into the wall, which is often enough to cause failures in the wall by itself.A haul road is situated at the side of the pit, forming a ramp up which trucks can drive, carrying ore and waste rock.

Waste rock is piled up at the surface, near the edge of the open cut. This is known as the waste dump. The waste dump is also tiered and stepped, to minimize degradation. Ore which has been processed is known as tailings, and is generally a slurry. This is pumped to a tailings dam or settling pond, where the water evaporates. Tailings dams can often be toxic due to the presence of unextracted sulfide minerals, some forms of toxic minerals in the gangue, and often cyanide which is used to treat gold ore via the cyanide leach process.

After mining finishes, the mine area must undergo rehabilitation. Waste dumps are contoured to flatten them out, to further stabilize them. If the ore contains sulfides it is usually covered with a layer of clay to prevent access of rain and oxygen from the air, which can oxidize the sulfides to produce sulfuric acid, a phenomenon known as acid mine drainage. This is then generally covered with soil, and vegetation is planted to help consolidate the material. Eventually this layer will erode, but it is generally hoped that the rate of leaching or acid will be slowed by the cover such that the environment can handle the load of acid and associated heavy metals. There are no long term studies on the success of these covers due to the relatively short time in which large scale open pit mining has existed. It may take hundreds to thousands of years for some waste dumps to become “acid neutral” and stop leaching to the environment. The dumps are usually fenced off to prevent livestock denuding them of vegetation. The open pit is then surrounded with a fence, to prevent access, and it generally eventually fills up with ground water. In arid areas it may not fill due to the deep groundwater levels.

Environmentalists in all countries oppose mining; oppose burning of coal. But nowhere they can ride over policy makers to keep mining suspended for years when the energy security is compromised by not adopting economic mining method as is the case in Bangladesh. In this context it will not be out of place to discuss almost a similar situation in Malaysia – a country having almost similar geographical, geological and environmental situation like Bangladesh.

Underground Coal mining

Underground coal gasification (UCG) is an industrial process, which converts coal into product gas. UCG is an in-situ gasification process carried out in non-mined coal seams using injection of oxidants, and bringing the product gas to surface through production wells drilled from the surface. The product gas could to be used as a chemical feedstock or as fuel for power generation. The technique can be applied to resources that are otherwise unprofitable or technically complicated to extract by traditional mining methods and it also offers an alternative to conventional coal mining methods for some resources.

Underground coal gasification converts coal to gas while still in the coal seam (in-situ). Gas is produced and extracted through wells drilled into the un-mined coal seam. Injection wells are used to supply the oxidants (air, oxygen, or steam) to ignite and fuel the underground combustion process. Separate production wells are used to bring the product gas to surface. The high pressure combustion is conducted at temperature of 700–900 °C (1,290–1,650 °F), but it may reach up to 1,500 °C (2,730 °F). The process decomposes coal and generates carbon dioxide (CO2), hydrogen (ḥ), carbon monoxide (CO) and small quantities of methane (CH4) and hydrogen sulfide(H2S). As the coal face burns and the immediate area is depleted, the oxidants injected are controlled by the operator

As coal varies considerably in its resistance to flow, depending on its age, composition and geological history, the natural permeability of the coal to transport the gas is generally not adequate. For high pressure break-up of the coal, hydro-fracturing, electric-linkage, and reverse combustion may be used in varying degrees.

Two methods are commercially available. One uses vertical wells and a method of reverse combustion to open internal pathways in the coal. The process was used in the Soviet Union and was later modified by Ergo Energy. It was tested in Chinchilla site in 1998–2003. Livermore developed another method that creates dedicated inseam boreholes, using drilling and completion technology adapted from oil and gas production. It has a movable injection point known as CRIP (controlled retraction injection point) and generally uses oxygen or enriched air for gasification.

According to the Commonwealth Scientific and Industrial Research Organisation the following coal seam characteristics are most suitable for the underground coal gasification:

Depth of 100–600 meters (330–2,000 ft)

Thickness more than 5 meters (16 ft)

Ash content less than 60%

Minimal discontinuities

There are a number of site specific technical factors which are important to the process. Coals with wide range of properties can be utilized, items of significance include

The geology of the coal seam must be continuous and preferably thicker than three meters.

The overburden should be more than 100m thick, relatively impermeable and with reasonable strength above the coal seam.

The water table preferably should be within 20m or from the ground surface to provide cavity water pressure to balance the oxidant injection pressure and limit product gas leak

While each of the above each of the above item is individually important, it is over an appraisal of many technical aspects of the site that govern sits suitability for development. Commercial matters like size of coal reserve and the market for the produced gas are also critical for the development of a project at a particular site.

Comparison between the methods

Bangladeshi policy makers may carry out some research on UCG .It is not very difficult to locate the real pioneers of UCG. Whether or not UCG can be applicable in any Bangladesh coalmine is subjected to extensive feasibility study by truly professional company of proven track record. It is too early to comment on suitability of Bangladeshi coal mines for UCG. Let Government find the most appropriate company from among handful companies involved in UCG in Australia, South Africa and Pakistan. Let there be authentic feasibility study. Minor companies can tell stories but they can do nothing practically. UCG is a highly sophisticated and sensitive technology. One of the early generation UCG pioneer Russian Canadian Mr Blinderman is now living in Canada. Bangladesh must not try amateur attempt to extract UCG from its mines as they did with Barapukuria coalmine pursuing inappropriate underground mining. If any of our mine qualify for UCG that must be established by experts of proven technology. But this must not bring any impediments to mining of coal from reserves which are suitable for traditional mining.

Professionals already mentioned time and again about applicability of Strip Mining [Open Pit] at Barapukuria and Phulbari. Many thinks a combination of Open pit and underground mining can work in Khalaspeer and Dighipara. Unfortunately detail feasibility study could only be carried out at Phulbari by internationally accredited consultants. . Even then policy makers could not take decision on Phulbari after 5 years of receipt of professional mining proposal. The in appropriate mining at Barapukuria has triggered disaster. The most suitable mine for strip mining is an opportunity lost. Barapukuria is proved to be a failed project yet triggered massive subsidence at very early stage of mining. It experienced all impacts of an failed underground long wall mining .Luckily there has been not many causalities so far.

For example:

The existence of the open-pit mine, in Mukah have proven to be a blessing to the Iban community because:

They benefitted directly from the land compensation given by the said mining company for rights to mine on their land. Evidence can be seen from the fact that many of the long houses locating on the Mukah Coalfield have utilised the money to upgrade their longhouses and to purchase other necessities to enjoy comfort of modern living.

Through employment received from the said mining company , the community can supplement their shifting cultivation income by the more consistent monthly wages earned working as mining crew.

A As they are expose to the usage of modern equipment , they are able to accelerate their assimilation into modern world of 21st century and this will augur well for the Iban community in general specially for the younger generation.

The open cut mining project in Mukah have brought substantial benefits to the local community and the State of Srawak, through such contribution as Royalties to the sate for extraction of coal, a better standard of living for the local community through direct and indirect employment and a general increase in business for the local businesses in Mukah Division.

There seems to be lot of similarities of Mukah region of Malaysia with our Phulbari, Barapukuria region. We can definitely try to learn lessons and try to replicate the good works. Malaysia is not very far from Bangladesh. Government can organize sending its officials, mining professionals, environmentalists to eye witness the mining activities, and management of social and environmental impacts of open pit mining. It is not a rocket science. We talk about digital Bangladesh. We still do not know what open pit mining is. Silly and ridiculous to keep our fortune buried while nation continues to suffer from serious energy crisis

COAL IN PROUCTION OF ELECTRICITY

Modern life is unimaginable without electricity. It lights houses, buildings, streets, provides domestic and industrial heat, and powers most equipment used in homes, offices and machinery in factories. Improving access to electricity worldwide is critical to alleviating poverty.

How is Coal Converted to Electricity

Steam coal also known as thermal coal is used in power stations to generate electricity.

Coal is first milled to a fine powder which increases the surface area and allows it to burn more quickly. In these pulverized coal combustion (PCC) systems the powdered coal is blown into the combustion chamber of a boiler where it is burnt at high temperature (see diagram below). The hot gases and heat energy produced converts water – in tubes lining the boiler – into steam.

The high pressure steam is passed into a turbine containing thousands of propeller-like blades. The steam pushes these blades causing the turbine shaft to rotate at high speed. A generator is mounted at one end of the turbine shaft and consists of carefully wound wire coils. Electricity is generated when these are rapidly rotated in a strong magnetic field. After passing through the turbine the steam is condensed and returned to the boiler to be heated once again.

The electricity generated is transformed into the higher voltages (up to 400,000 volts) used for economic efficient transmission via power line grids. When it nears the point of consumption, such as our homes the electricity is transformed down to the safer 100-250 voltage systems used in the domestic market.

Electricity sector in Bangladesh

Bangladesh’s energy infrastructure is quite small insufficient and poorly managed. The per capita energy consumption in Bangladesh is one of the lowest (136 kWH) in the world. Noncommercial energy sources such as wood, animal wastes, and crop residues are estimated to account for over half of the country’s energy consumption. Bangladesh has small reserves of oil and coal but very large natural gas resources. Commercial energy consumption is mostly natural gas (around 66%) followed by oil, hydropower and coal.

Electricity is the major source of power for country’s most of the economic activities. Bangladesh’s installed electric generation capacity was 4.7 GW in 2009 only three-fourth of which is considered to be ‘available’. Only 40% of the population has access to electricity with a per capita availability of 136 kWh per annum. Problems in the Bangladesh’s electric power sector include corruption in administration, high system losses, delays in completion of new plants, low plant efficiencies, erratic power supply, electricity theft, blackouts, and shortages of funds for power plant maintenance. Overall the country’s generation plants have been unable to meet system demand over the past decade.

In generating and distributing electricity the failure to adequately manage the load leads to extensive load shedding which results in severe disruption in the industrial production and other economic activities. A recent survey reveals that power outages result in a loss of industrial output worth $1 billion a year which reduces the GDP growth by about half a percentage point in Bangladesh. A major hurdle in efficiently delivering power is caused by the inefficient distribution system. It is estimated that the total transmission and distribution losses in Bangladesh amount to one-third of the total generation the value of which is equal to US $247 million per year.

Developing Thar Coal In Bangladesh

Coal is the cheapest source of energy consumed the world over playing a pivotal role in the generation of power for the smooth operation of industries. Thar coal is said to be one of the largest coal reserves in the world situated in Tharparkar Sindh. Coal is the most important source used for generating electricity in most of the developed and developing countries.

The authentic statistics of the World Coal Institute, London published in 2006 say that the share of the coal in the production of power in the United States is about 52.2 per cent while China produces 77.5 per cent of its total electricity by using coal.

The share of coal in the production of electricity is 92.2 per cent in South Africa. Our closest neighbor (India) meets approximately 70 per cent of its power needs through coal whereas we are using just five per cent of our coal for energy production.

Several MoUs were signed between the past government of the PPP and multinational exploration companies which even invested and began working on the infrastructural development of the area but after the removal of the PPP government Mian Nawaz Sharif scrapped those coal development projects on political grounds.

During the Musharraf regime a Chinese company was invited to invest in the project aimed at generating 600 MW of electricity but due to unfriendly attitude of Wapda and Nepra the Chinese company had to quit.

Now when we are facing the worst-ever energy crisis we must start developing Thar coalfields. The Sindh Coal and Energy Board has been established under the chairmanship of the Sindh Chief Minister which has still to show its performance. To end the energy crisis once for all development of Thar coal is the most feasible option available.

Power Generation In Bangladesh

In November 2010 Reuters reported that the Bangladesh Power Development Board (BPDB) had announced the aim of generate 9,000 megawatts of electricity by 2015. The country currently produces approximately 4,000 MW of electricity a day “against peak hourly demand of over 6,000 MW.

The BPDB called for tender bids on a number of new power plants including two coal-fired plants. One is a 300MW coal plant to be built near Chittagong port. The tender closes at the end of January 2011. The board has also sought tenders for a 650MW coal plant to be built near Mawa. Both projects are proposed to be constructed on a build own and operate basis for 25 years. Reuters reported that BPDB officials stated that in the near future thwy would call for bids for 10 new power plants to add another 4,000 megawatts of electricity to the national grid.

Local coal for power generation

THE Power Development Board (PDB) has reportedly proposed last week to form a public limited company to install coal-based power plants in future. According to PDB sources four mega coal-based power plants having capacity of producing 500 megawatt of electricity each would be established under the supervision of the proposed company by 2014. Several companies have already expressed interest to establish the plants under Public Private Partnership.

The country suffers from a serious shortage of electricity. According to sources the total generation comes to 3,200mw of electricity against the demand for 4,600mw. The crisis has reached a point of seriously hampering production in mills and factories. Several power plants are reportedly producing electricity less than their capacities. Some others have stopped production due to short supply of gas that fuels 80 percent of power generation. According to a projection, the country will need about 10,000mw and 14,000mw electricity by 2015 and 2020 respectively. But except for limited reserves of gas there is only coal to fuel power plants. So the proposal for installation of coal-based power plants is a step in the right direction.

It has been reported that PDB would use imported coal to run the proposed plants. Bangladesh has a proven reserve of 2,086 million tons of high quality coal. According to experts this coal is enough to generate 5,000mw of electricity for up to 90 years. It will also save about US$500 million that the country spends annually to import coal. Petrobangla had in June even proposed to export two lakh tons of coal from Barapukuria due to storage problem. Then what is the reason behind the idea of using imported coal instead of the local coal. The country should go for early extraction of its own coal resource.

New company to be set up to increase coal-based power generation

The government will form a new company styled ‘Bangladesh Coal Power Company’ to set up the planned coal-fired power plants and increase the country’s electricity generation by using the mineral officials. The power ministry has already decided to create the company after enlisting it with the Registrar of the Joint Stock Companies and Firms (RJSCF).

The proposed new company will boost electricity generation from coal which is abundant in northern Bangladesh. Immediately after formation of the company it will be engaged to facilitate setting up four coal-fired power plants to generate 2,000 megawatts (mw) of electricity each having generation capacity of 500 mw.

The power ministry has taken up the program for installing four coal-fired

power plants under the new concept of the private public partnership (PPP) where the government will own only a fraction of its shares for offering land and infrastructure. It will require around US$ 3.0 billion (Tk 210 billion) for setting up these coal plants. When contacted Chairman of Bangladesh Power Development Board (BPDB) ASM Alamgir Kabir said the board is now working on the formation of the new company to augment electricity generation from the coal-fired power plants.

The company will be constituted with the efficient people where some BPDB officials will also get appointment. The BPDB has already initiated the groundbreaking work and is now selecting sites for setting up the plants. It has primarily selected – Karnaphuli river bank in Chittagong near Mongla seaport in Khulna, Jazira on the bank of Padma and at Meghnaghat on the bank of Meghna – for setting up the plants for smooth transportation of coal.

Initially the planned power plants will be run with the imported coal from the global markets including the key exporting countries like Indonesia, Australia and India. The existing infrastructure like drafting in waterways and expansion of railway tracks will be required for efficient coal transportation, said a power ministry official. All the four proposed coal-fired power plants along with some independent power producer (IPP) projects will be put on offer during the road shows in three key important locations – New York, London and Singapore – in December next.

The major task of the proposed company will be to arrange finance necessary coal supply and develop required infrastructure. Despite having enormous coal reserves of around 3.0 billion tones in five different mines the country’s coal-fired power generation is limited to only one plant at Barapukuria having the generation capacity of 250 mw. Even the Barapukuria plant is struggling to generate electricity to half of its installed capacity.

The country is waiting for adoption of a national coal policy to start coal extraction from the mineral-rich northern region. The country’s overall electricity generation is now hovering around 3,800mw against the peak hour demand for over 5,500mw.

Bangladesh seeks bids for 300 MW coal-fired plant

Bangladesh has invited bids for a 300-megawatt coal-fired power plant to be set up on a build, own and operate basis (BOO) for 25 years. The tender for the plant to be built near the country’s main Chittagong port 300 km (188 miles) southeast of the capital will close on Jan. 31, next year. The bids have been invited as part of a government initiative to generate 9,000 MW of electricity by 2015.The BPDB is the regulator for power generation and distribution in the country where the gap between demand and generation has been growing.

Bids for a short-list of viable firms have also been invited for another 650 MW coal-fired plant to be set up at Mawa 50 km (31 miles) east of the capital, Dhaka also on a BOO basis and for 25 years. The bids for the short-list will close on Dec. 30.Energy-starved Bangladesh which faces a deficit of 2,000 MW of power aims to set up a number of power plants to cover the shortfall as quick as possible.

BPDB awarded a $114 deal to a Chinese firm — China National Machinery Import and Export Corporation to set up a 150 MW power plant in northern Sirajganj by May 2012. BPDB in the recent months signed deals with several foreign and local firms to set up plants or to buy electricity from their rental plants. Britain’s Aggreko PLC and seven other local firms were given deals to supply some 870 megawatts of power to the national grid for five years starting later this year.

Aggreko has already started generating 200 MW from two fuel oil-fired rented generator from August at $0.21 per kilowatt-hour. The British firm also won another deal last month to supply more 150 MW to the Bangladesh national grid from its two small gas-fired plant from February for three years at $0.07 per kilowatt-hour. Bangladesh will soon seek bids for 10 new power plants to add another 4,000 megawatts of electricity to the national grid.

US firms keen to invest in coal sector

American companies are keen to invest in Bangladesh’s coal sector. The US envoy apprised him that American energy companies are interested to help Bangladesh in developing energy sector. They particularly want to invest in coal mining after finalization of the coal policy by the government.

Moriarty noted that the United States would provide necessary assistance for the victims if Bangladesh side seek any help.A number of US companies including oil major Chevron have been operating in the country’s energy and power sector. But this is the first time it was learned that US energy companies are also interested in the coal mines.

Bangladesh has about five coal mines in the country’s northern region, having a total coal deposit of 2.5 billion tons.

Coal In Electrical Power System

World coal fired power plant capacity will grow from 1,759,000 MW in 2010 to 2,384,000 MW in 2020.Some 80,000 MW will be replaced.So there will be 705,000 MW of new coal fired boilers sales will average 70,000 MW.

Coal fired power plants generate approximately 56% of the U.S electricity.A healthy economy requires the effective utilization of the existing infrastructure as new technologies are introduced.Coal plays a vital role in electricity generation worldwide.Coal fired power plant currently fuel 41% of global electricity.In some countries coal fuels a higher percentage of electricity.Germany is one of the major nation who converts coal in electricity generation.In 2008 the gross electric power generation in Germany totalled 639 billion KWH.A major proportion of the electricity supply is based on lignite (23.5%), nuclear energy (23.3%) and hard coal (20.1%).Natural gas has a share of 13% renewables (wind,water,biomass) account for 15.1%.

Coal In Electricity Generation Outside Bangladesh

Name Of The Country

- Total Generation

- South Africa 93%

- Australia 77%

- USA 49%

- India 69%

- Germany 46%

Kogan creek power station of Australia has a capacity of 7636 MW and it produces 2.46% of electricity.Hassyan power station of Arab Emirates has a capacity of 9000 MW and it produces 1.35% of electricity.Altbach power station of Germany has a capacity of 1200 MW and it produces 0.18% of electricity.Cottam power station of United Kingdom has a capacity of 2000 MW and it produces 3.5% of electricity.

Improvements continue to be made in conventional power station design and new combustion technologies are being developed.These allow more electricity to be produced from less coal known as improving the thermal efficiency of the electrical power station.Coal will continue to be a valued resource with over 100 GW of new coal plants projected by 2020.Advanced technology is required to meet economic and environmental goals.It also maintaining diversity manufacturing capabilities also mention environmental goals as its security concern.

Carbon Dioxide Emission Factors For Coal Across The World

Coal is an important source of energy across the world and the whole world depends on this fossil fuel for electricity generation is growing.The combustion of coal also adds a significant amount of carbon dioxide to the atmosphere per unit of heat energy.In modern days a growing concern over the possible consequences of global warming which may be caused in part by increases in atmospheric carbon dioxide (a major greenhouse gas) and also because of the need for accurate estimates of carbon dioxide emissions .The Energy Information Administration (EIA) has a developed factors for estimating the amount of carbon dioxide emitted as a result of coal consumption. EIA’s emission factors will improve the accuracy of estimates of carbon dioxide emissions because they reflect the difference in the ratio of carbon to heat content by rank of coal and state of origin.

Two types of carbon dioxide emission factors have been developed. First are basic emission factors covering the various coal ranks by State of origin. These basic emission factors are considered as “fixed” for the foreseeable future until better data become available. Second are emission factors for use in estimating carbon dioxide emissions from coal consumption by State with consuming-sector detail. These emission factors are based on the mix of coal consumed and the basic emission factors by coal rank and State of origin. These emission factors are subject to change over time, reflecting changes in the mix of coal consumed.

EIA’s emission factors will not only enable coal-generated carbon dioxide emissions to be estimated more accurately than before but they will also provide consistency in estimates. Energy and environmental analysts will find EIA’s emission factors useful for analyzing and monitoring carbon dioxide emissions from coal combustion, whether they are estimated by the State of origin of the coal, consuming State, or consuming sector.

West of the Mississippi River the emission factors for bituminous coal range from more than 201 pounds of carbon dioxide per million Btu in Missouri, Iowa, and Nevada to more than 209 in Arizona, Arkansas, and Montana. About 16 percent of the 1992 coal output west of the Mississippi was bituminous coal with production chiefly from Utah, Arizona, Colorado and New Mexico.

Sub bituminous coal is the predominant rank of coal produced west of the Mississippi River accounting for 62 percent of the region’s total coal output in 1992. Sub bituminous coal in Wyoming’s Powder River Basin the principal source of this rank of coal, has an emission factor of 212.7 pounds of carbon dioxide per million Btu. This is the same as for sub bituminous coal in Colorado, but slightly below that in Montana. The lowest emission factor for sub bituminous coal is in Utah (207.1) and the highest is in Alaska (214.0).

Coal Costs

On the heels of President Obama’s speech supporting clean coal it doesn’t seem that this energy source is leaving anytime soon. But while advocates often tout the inexpensiveness of coal a new study reveals that the substance may be costing the U.S. up to $500 billion per year.

Harvard professor and Huffington Post contributor Paul Epstein( M.D., M.P.H.) has just announced the release of a new study in the Annals of the New York Academy of Sciences entitled “Full Cost Accounting For the Life Cycle Of Coal.”

According to Tree Hugger Epstein’s study is considered one of the first to examine the costs of coal in its entirety – from extraction to combustion. So how did Epstein reach the astronomical number of $500 billion/yr.

First, public health costs. In Appalachian communities alone health care, deaths, and injuries from coal mining and transporting cost $74 billion per year. Beyond Appalachia, the health costs of cancer, lung disease, and respiratory illnesses related to pollutant emissions totals $187.5 billion per year. According to Climate Progress, processing coal releases heavy metal toxins and carcinogens which in turn may lead to long-term health problems. The American Lung Association reports on a study finding that coal-powered electricity caused over 13,000 premature deaths in 2010.

Beyond health problems add the cost of coal’s effect on land use energy consumption and food prices plus the cost of toxic waste spills and cleanup… $500 billion. The public is unfairly paying for the impacts of coal use. Accounting for these ‘hidden costs’ doubles to triples the price of electricity from coal per kWh, making wind, solar, and other renewable very economically competitive.

According to Epstein, we must focus more on green city planning. Most importantly, “We need to phase out coal rapidly.”

Tapping Coal For Clean And Low-cost electricity In Bangladesh

Australian firm proposes to generate 400MW power from Bangladesh’s unmineable coal by 2015. An Australian company with expertise in underground coal gasification (UCG) technology has proposed to produce 400 megawatts of clean coal power from Bangladesh’s unmineable coal within five years at a very low cost.

Making a presentation to Petrobangla Mitchell Group of Australia said it could undertake a pilot project at its own cost in the deeper part of Barapukuria coal mine or in Jamalganj.

The first phase delivery of 10 to 40 MW power from the pilot project is possible within two years — 2011-12. By 2015, the company will be able to deliver 400 MW power.

Sources present at the presentation said it is very lucrative as power generated from such a plant will be as cheap as that produced by using gas. A part of Barapukuria is presently unmineable by using open pit or underground mining methods as coal rests at a depth of 500 metres.

On the other hand the coal deposit in Jamalganj is by far the biggest one discovered in the country. Jamalganj has more than one billion tones of coal. Unfortunately the deposit rests between 600 and 1,100 metres below the surface making it inaccessible using conventional mining methods.

The Costs of Generating Electricity

• Coal plant

• Pulverized fuel (PF) steam plant.

• Circulating fluidized-bed combustion (CFBC) plant.

• Integrated gasification combined-cycle (IGCC) plant.

• Gas plant.

• Open-cycle gas turbine (OCGT) plant.

• Combined-cycle gas turbine (CCGT) plant.

• Nuclear fission plant.

• Biomass (poultry litter)

• Bubbling fluidized-bed combustion (BFBC) plant;

• Wind turbines

The cost of generating electricity, as defined within the scope of this study, is expressed in terms of a unit cost (pence per kWh) delivered at the boundary of the power station site. This cost value, therefore, includes the capital cost1 of the generating plant and equipment; the cost of fuel burned (if applicable); and the cost of operating and maintaining the plant in keeping with UK best practices. Within the study, however, the ‘cost of generating electricity’ is deemed to refer to that of providing a dependable (or ‘firm’) supply. For intermittent2 sources of generation, such as wind, an additional amount has been included for the provision of adequate standby generation.

Hydroelectric is the most cost effective at $0.03 per kWh. Hydroelectric production is naturally limited by the number of feasible geographic locations and the huge environmental infringement caused by the construction of a dam. Nuclear and coal are tied at $0.04 per kWh. This comes as a bit of a surprise because coal is typically regarded as the cheapest form of energy production. Another surprise is that wind power ($0.08 per kWh) came in slightly cheaper than natural gas ($0.10 per kWh). Solar power was by far the most expensive at $0.22 per kWh—and that only represents construction costs because I could not find reliable data on production costs. Also, there is a higher degree of uncertainty in cost with wind and solar energy due to poor and varying

data regarding the useful life of the facilities and their capacity factors. For this analysis the average of the data points are used in the calculations.

Extrapolation of Results

- Energy Source % of Total Cost per kWh Weighted Avg Cost

- Nuclear 19.7% $0.04 $0.008

- Hydro 6.1% $0.03 $0.002

- Coal 48.7% $0.04 $0.022

- Natural Gas 21.4% $0.10 $0.022

- Petroleum 1.1% $0.10 $0.001

- Other Renewables 3.0% $0.15 $0.005

- 100% $0.059

Least-Cost Analysis of Bangladesh

About 85% of electricity in Bangladesh is produced from gas-based power plants. Coal,

Hydropower, heavy fuel oil (HFO) and diesel are the other sources of energy for power generation. Inadequate investment in upstream gas field development in recent years has resulted in a shortage of gas for the industrial sector and for electricity generation. This has constrained power generation with electricity utilities resorting to load shedding while industrial consumers have been using captive generation facilities that require diesel. As an immediate measure to reduce gas shortage the government has decided not to provide assured gas supply to a number of new power projects and has asked promoters to develop these projects on a dual fuel model (to be run on diesel or HFO).

Indicates the cost of power generation using various fuels in Bangladesh:

Fuel Source Economic Generation Cost Per Unit Tk/kWh

Gas 4.2

Coal (local) 3.7

Coal (Imported) 5.4

HFO 12.1

Diesel 25.2

Hydropower 1.4

Bangladesh has sizable coal reserves in the north-west region, currently only one coal-based power plant is operating and it has been facing fuel shortages given constraints in coal production. The development of domestic coalfields will take time and will require significant investment. Imported coal-based power generally costs about Tk 5.4/kwh ($0.077) at current coal prices. In the current situation, power imports fromIndia3 are expected to be the most feasible least-cost way of overcoming existing power shortages in Bangladesh.

Cost of Barapukuria Coal Mine Project

Total Cost : US$ 197million

US$: 172 million in F.C.

US$: 25 million in L.C.

Expected annual production: 1.2 million tons

Market price: US$ 90 million

Annual production cost: US$ 40.8 million

Foreign currency worth: US$ 45 million will be saved per annum

64 years will be required to extract 300 million tons of coal at the above rate

The discovery of such huge deposits of coal and hard rock is a blessing for Bangladesh and proper development of these resources will open a new era for the country to enter the industrial world. In the modern world the sustainable economic conditions of any nation depend on how developed that country’s industrial is especially in the field of mineral resources. So minerals based industries are an important factor for accelerating the economic growth of a country. Now Bangladesh has an opportunity to build up mineral-based industries as she has sufficient mineral resources on which industries can develop. Full-capacity exploitation of these resources will create thousands of new jobs at the mine sites and later on at industrial sites which will help to alleviate the country’s poverty by providing jobs. All these together will accelerate the country’s economic development. It may be concluded that proper development and utilization of these resources will help us to save a considerable amount of foreign currency and will contribute a great deal to the national economy and reshape our socio-economic infrastructure.

MERITS & DEMERITS OF COAL BASED POWER PLANT

Merits of coal fired power plant

1. Coal is a stable energy source

2. Coal is a key source of power generation

3. High efficiency

4. Low cost

5. Low maintenance

Looking at other countries, coal makes up 50% of power generation in the USA, the largest consumer of energy, and 80% in China, where rapid growth in energy consumption is forecast. As coal accounts for 41% of the world’s power generation, it will continue to play a major role for the foreseeable future.

Emissions to air

The principal emissions from burning coal are carbon dioxide (CO2), sulphur dioxide (SO2), oxides of nitrogen (NOX), hydrogen chloride (HCl), and particulates (dust). Our generating units have all been retrofitted with Flue Gas Desulphurization (FGD) equipment which removes at least 90% of SO2 and HCl emissions before the flue gas is released via the chimney into the atmosphere.

We maintain investment in our emissions abatement equipment and consider this to be a high priority. Our FGD plant already complies with known future SO2 emissions limits to 2016. In 2008 we completed a programme to retrofit all units with low NOX technology – Boosted Over Fire Air systems – in order to ensure compliance with the NOX requirements of the Large Combustion Plant Directive (LCPD) which were strengthened in 2008.

6.1.2 Discharges to water

Procedures are in place to ensure that all discharges and drainage to water are monitored and treated where necessary to meet our discharge consent limits. There are a number of sources of discharge and drainage as part of the electricity generation process, including the cooling water used to cool the condensers, which as part of the steam cycle condense steam to water after it leaves the turbines and before returning to the boilers. Cooling water is abstracted mainly from the River Ouse and boiler feed water originates from two boreholes on site. Approximately half of the water is returned to the River Ouse at a few degrees warmer than the river water.

The FGD process produces effluent water which is treated in a specially designed plant before it is discharged to the river, and there is also drainage from the main plant, coal plant and roads.

Disposals to land

When coal is burnt, ash is left as a residue. The finer particles of ash, pulverised fuel ash (PFA,) are collected from the flue gas by electrostatic precipitators; the heavier ash, furnace bottom ash (FBA) falls to the bottom of the boiler. The majority of ash is sold to the construction industry with the remainder sent for landfill at the power station’s adjacent Barlow Mound ash disposal site, which over time has been developed into farmland, woodland and wetland features providing a haven to many species of wildlife and birdlife.

We pay landfill tax on the PFA disposed of to the Barlow Mound. Through the Landfill Tax Credit Scheme, we are able to claim a tax credit against our donations to recognised Environmental Bodies. We have worked with Groundwork Selby since 2001 on projects designed to help mitigate the effects of landfill upon our local community.

Environmental impacts of coal power