With the constant rising and falling of temperatures during the cold winter months, potholes are always a major issue for Indiana’s roads. Potholes form when water seeps into small cracks in road pavement, then freezes and expands, causing the pavement to crumble and form a large hole in which your car can be damaged if you hit it just right.

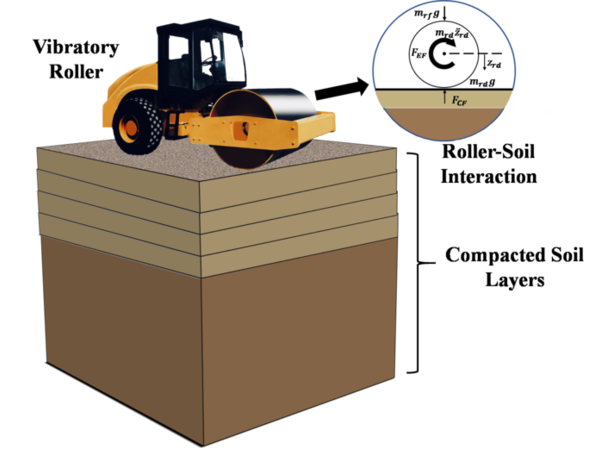

Researchers have created a new “intelligent compaction” technology that integrates into a road roller and can assess the quality of road base compaction in real-time. Improved road construction can reduce potholes and maintenance costs while also making roads safer and more resilient.

Months of heavy rain and flooding have highlighted the value of road quality, with poor construction resulting in potholes and road subsidence. This not only results in tyre blowouts and structural damage to cars and trucks, but it also increases the likelihood of serious accidents.

A research team from the University of Technology Sydney developed a novel machine-learning technique, which processes data from a sensor attached to a construction roller. Associate Professor Behzad Fatahi, head of geotechnical and transport engineering, led the research along with Professor Hadi Kahbbaz, Dr. Di Wu, and Ph.D. student Zhengheng Xu.

We developed an advanced computer model that incorporates machine learning and big data from construction sites to predict the stiffness of compacted soil with a high degree of accuracy in a fraction of a second, so roller operators can make adjustments.

Associate Professor Fatahi

“We developed an advanced computer model that incorporates machine learning and big data from construction sites to predict the stiffness of compacted soil with a high degree of accuracy in a fraction of a second, so roller operators can make adjustments,” Associate Professor Fatahi explained.

Roads are made up of three or more layers, which are rolled and compacted. The subgrade layer is usually soil, followed by natural materials such as crushed rock, and then asphalt or concrete on top. The variable nature of soil and moisture conditions can result in under or over-compacted material.

“Like Goldilocks, the compaction needs to be ‘just right’ to provide the correct structural integrity and strength. Over-compaction can break down the material and change its composition, and under-compaction can lead to uneven settlement,” said Associate Professor Fatahi.

“A well-compacted multi-layer road base provides a stable foundation and increases the capacity of a road to bear heavy loads. Trucks can weigh up to 40 tonnes, so a poor quality base can quickly lead to cracks and weak spots in the asphalt surface.”

The study, which was recently published in the peer-reviewed journal Engineering Structures, suggests that using this technology could help build longer-lasting roads that can withstand harsh weather conditions.

The team plans to test the new technology on-site for various ground and roller conditions for road, railway, and dam construction projects, as well as investigate techniques for measuring the density and moisture content of compacted soil in real-time during construction.