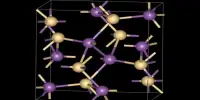

Potassium ferrate is an inorganic compound with the formula K2FeO4. It is the potassium salt of ferric acid. Potassium ferrate is a powerful oxidizing agent with applications in green chemistry, organic synthesis, and cathode technology.

It is used for water and wastewater treatment (oxidation/disinfection, simultaneous coagulation because Fe(III) forms), organic synthesis (selective oxidations), pollutant remediation, and as a potential eco-friendly oxidant in advanced oxidation processes and battery research.

Synthesis

Common preparative routes oxidize iron(III) compounds in strongly alkaline potassium media using powerful oxidants (e.g., hypochlorite, ozone, or electrochemical methods), then isolate the purple salt.

Properties

It appears as deep purple to dark-purple crystalline solids and has a molar mass ≈198.04 g·mol⁻¹. The ferrate anion (FeO₄²⁻) is a very strong, selective oxidizing agent and shows high redox potential in alkaline media. It is soluble in water but hydrolyzes and slowly decomposes, especially at neutral or acidic pH, yielding iron(III) oxides/hydroxides and oxygen. It is most stable in strongly alkaline solutions (high pH) and at low temperature.

- Chemical formula: K2FeO4

- Molar mass: 198.0392 g/mol

- Appearance: Dark purple solid

- Density: 2.829 g/cm3

- Melting point: >198 °C (decomposes)

- Solubility in water: soluble in 1M KOH

- Stability: Stable in solid form, but decomposes in water, especially under acidic or neutral conditions, releasing oxygen and forming Fe(III) compounds.

- Oxidizing ability: Stronger than potassium permanganate (KMnO₄), making it one of the most powerful oxidizing agents known.

- Magnetism: Diamagnetic.

- Reactivity: Reacts vigorously with reducing agents, acids, and organic materials.

Synthesis

Generally, there are three ways to produce hexavalent iron: dry oxidation, wet oxidation, and electrochemical synthesis. The methods used to produce potassium ferrate are similar to those used to produce sodium ferrate and barium ferrate.

Dry oxidation

The dry oxidation method entails heating or melting iron oxides in an alkaline, oxygenated environment. The combination of high temperature (200 °C – 800 °C) and oxygen presents an explosion hazard that has led many researchers to believe this method of production is not suitable from a safety viewpoint, although many attempts have been made to overcome this problem.

Occurrences

- Potassium ferrate does not occur naturally due to the instability of the ferrate(VI) ion in natural environments.

- It is synthetically produced, usually by oxidizing iron in a strongly alkaline medium with an oxidizer such as chlorine, hypochlorite, or ozone.

- Commonly prepared through reactions involving potassium hydroxide and oxidizing agents.