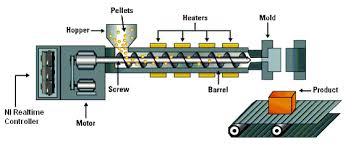

Plastic Injection Molding is a manufacturing process pertaining to producing parts simply by injecting material in to a mould. Injection moulding can be carried out with a number of materials, which includes metals, glasses, elastomers, confections, and the majority commonly thermoplastic and also thermosetting polymers. Material with the part is fed in to a heated barrel, blended, and forced in to a mould cavity, where it cools and hardens towards the configuration of the particular cavity. Plastic Injection Molding manufacturers use several distinct molding techniques to produce plastic factors. These techniques include things like thermoplastic and thermoset injection molding, blow molding, gyratory molding, thermoforming, structural foam molding and others.

Plastic Injection Molding