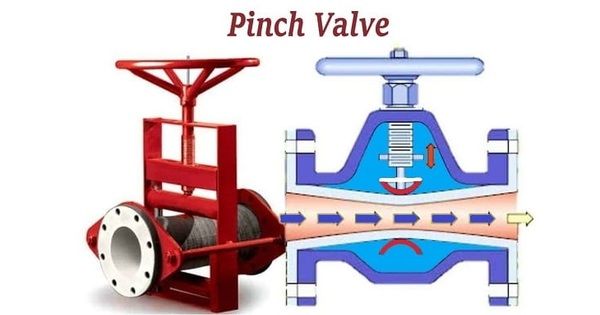

A pinch valve is a valve that controls the flow of a fluid (liquid or gas) by pinching a flexible tube or sleeve to restrict or block it. It is a full bore or fully ported control valve that uses a pinching effect to prevent fluid flow. It works by compressing or squeezing a segment of tubing, effectively stopping the flow of fluid.

Pinch valves are frequently employed in applications where the fluid being handled is abrasive, corrosive, or contains suspended solids, because the tube or sleeve is the only element of the valve that comes into contact with the fluid and can be quickly replaced if worn or damaged. They are commonly found in industries such as pharmaceuticals, food and beverage, wastewater treatment, and mining.

Operating principle

Pinch valves use elastic tubing (sleeve/hose) and a device that is in direct touch with the tubing (body). Forcing the tube together will result in a seal equal to the tubing’s permeability.

Air-operated pinch valves are made out of an elasticized reinforced rubber hose, a housing, and two socket end caps (or flanges). The rubber hoses in air-operated pinch valves are typically press-fitted and centered in the housing ends by the socket covers. There is no additional actuator, and the valve closes as soon as a pressurized air supply enters the body. When the air supply is cut and the volume of air is exhausted, the elastic rubber hose begins to open due to the force of the process flow.

Importance and applications

- Controlled Flow: These are used to control the flow of fluids, gases, slurries, and powders. Their simple design involves a flexible tube being squeezed or pinched to regulate the flow.

- Biomedical and Pharmaceutical Applications: In industries like biotechnology and pharmaceuticals, where contamination control is crucial, pinch valves find extensive use.

- Food and Beverage Industry: These are employed in the food and beverage industry for handling various fluids and ingredients. They are used in processes such as food processing, bottling, brewing, and dairy production.

- Water and Wastewater Treatment: In water treatment plants, pinch valves are utilized for controlling the flow of water, sludge, and chemicals. Their resistance to corrosion and ability to handle slurries make them suitable for these applications

- Pulp and Paper Industry: In pulp and paper manufacturing, pinch valves are used for controlling the flow of various chemicals, slurries, and wastewater. Their resistance to corrosion and ability to handle abrasive materials make them suitable for applications such as pulp bleaching, paper coating, and wastewater treatment in paper mills.