An oscillating U-tube, often known as a U-tube manometer, is a simple device for measuring pressure variations in a fluid. It is made up of a U-shaped tube that is partially filled with a liquid, usually water or mercury, and is connected to the system that will be used to monitor pressure. When there is a pressure differential between the two arms of the U-tube, the liquid levels in the arms adjust until the pressures are equal.

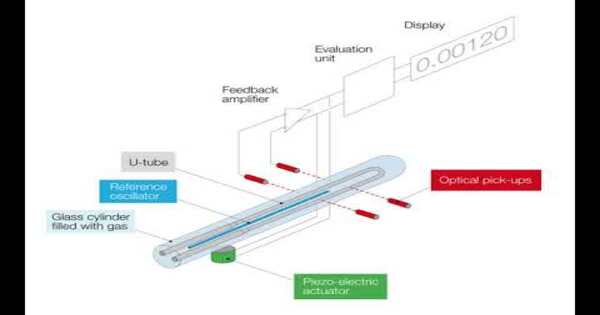

The oscillating U-tube technique determines the density of liquids and gases by measuring the frequency of oscillation using an electrical device and calculating the density value. This measurement principle is based on the Mass-Spring Model.

The oscillation of the liquid column is caused by a balance between the pressure exerted by the fluid in the system and the weight of the liquid column in the U tube. If the pressure in one arm of the U-tube rises relative to the other, the liquid will flow from the high-pressure side to the low-pressure side until equilibrium is achieved.

The sample is placed in a container with oscillation capabilities. This container’s eigenfrequency is influenced by the sample’s mass. This oscillation-capable container is a hollow, U-shaped glass tube (oscillating U-tube) that is electronically aroused into undamped oscillations. The two branches of the U-shaped oscillator serve as its springs.

Oscillations can arise when there are periodic pressure fluctuations in the system being measured. These fluctuations can cause the liquid column in the U-tube to oscillate back and forth. The frequency and magnitude of the oscillations can be used to learn about the system’s dynamics.

U-tube manometers are widely used in a variety of applications, including detecting pressure differentials in HVAC systems, monitoring fluid levels in tanks, and calibrating pressure sensors. They are simple, dependable, and inexpensive pressure gauges.