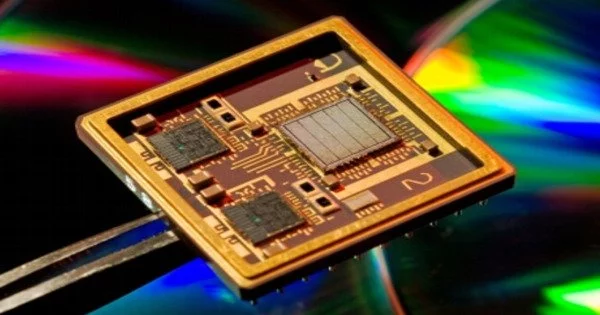

A multi-chip module (MCM) is a generic electronic assembly (such as a package with a number of conductor terminals or “pins”) that integrates multiple integrated circuits (ICs or “chips”), semiconductor dies, and/or other discrete components, typically onto a unifying substrate, so that it can be treated in use as if it were a larger IC. MCM packaging is also known as “heterogeneous integration” or “hybrid integrated circuit”.

Two or more chips are mounted and interconnected within a common package in an MCM, allowing them to function as a single unit. MCMs are used to improve the performance, functionality, and reliability of electronic systems. MCMs can reduce the size and weight of the overall system while improving electrical performance by integrating multiple chips into a single package. MCMs are widely used in high-performance computing, telecommunications, aerospace, and consumer electronics.

Types

MCMs are classified into two types: ceramic MCMs and organic MCMs. Ceramic MCMs are built on a ceramic substrate, which provides excellent electrical and thermal conductivity. Organic MCMs rely on organic substrates, such as printed circuit boards (PCBs), which are typically less expensive and more flexible than ceramic substrates but may provide less electrical performance.

Various techniques, such as wire bonding, flip-chip bonding, or through-silicon vias (TSVs), are used to connect the chips within an MCM. Wire bonding connects the chips with tiny wires, whereas flip-chip bonding directly mounts the chips face-down on the substrate and makes electrical connections with solder bumps. TSVs are vertical electrical connections that pass through the silicon substrate, allowing chips to communicate directly with one another.

Advantages

MCM packaging has the advantage of allowing a manufacturer to use multiple components for modularity and/or to improve yields over a traditional monolithic IC approach.

MCMs have several advantages over single-chip solutions. They can provide more processing power and bandwidth by combining multiple chips that specialize in different tasks like processing, memory, or communication. MCMs also allow for greater integration and miniaturization, resulting in smaller and less complex electronic systems. Furthermore, by incorporating redundant components or providing better thermal management, MCMs can improve system reliability.

An MCM operates as a single component and can handle an entire function. A MCM’s various components are mounted on a substrate, and the substrate’s bare dies are connected to the surface via wire bonding, tape bonding, or flip-chip bonding. The module can be encased in plastic molding and mounted on a printed circuit board. MCMs provide better performance and can significantly reduce device size.

Overall, multi-chip modules play a crucial role in advancing electronic systems by enabling higher performance, increased functionality, and improved reliability in a compact and efficient package.