Elastic nozzles, also known as flexible nozzles, are designed to produce more stable liquid jets compared to traditional rigid nozzles. This is because they are able to adjust their shape in response to changes in the fluid flow, which helps to reduce the amount of turbulence and instability in the jet. This can lead to a more consistent and precise spray pattern, which is useful in a variety of industrial and scientific applications, such as spray drying, coating, and atomization.

Until now, the flow of liquid through deformable elastic nozzles has received little attention. The concept of passively deforming nozzles is introduced in new research, which shows that softer nozzle materials can produce more stable jets across a wide range of flow rates.

A liquid jet will eventually break up into a string of droplets when squirted through a nozzle. Previous research found that the distance from the nozzle where this breakup occurs is affected by a variety of factors, including the shape of the nozzle and the movement of the air surrounding the jet.

Cleaning, cutting, inkjet printing, and drug delivery in medicine are just a few of the applications for liquid jets. Across these various scenarios, it is frequently critical for users to control the distance at which these jets break up, allowing them to fine-tune the frequency and size of the resulting drops as they hit their targets.

However, elastic nozzles, which can deform as liquids pass through them, have received little attention thus far. A team led by Andrew Dickerson at the University of Tennessee, USA, introduces the concept of passively-deforming nozzles in new research published in EPJ ST, demonstrating that softer nozzle materials can produce more stable jets across a wide range of flow rates.

Cleaning, cutting, inkjet printing, and drug delivery in medicine are just a few of the applications for liquid jets. Across these various scenarios, it is frequently critical for users to control the distance at which these jets break up, allowing them to fine-tune the frequency and size of the resulting drops as they hit their targets.

This length is tied to several different factors: including surface tension, liquid viscosity, and jet velocity. Currently, methods for controlling the breakup length include mixing the jet with a flowing gas, altering the nozzle’s geometry, and manipulating the jet after leaving the nozzle.

The flexibility of the nozzle allows it to maintain a constant flow rate and produce a more consistent jet, even in the presence of disturbances or variations in the fluid flow. This can be useful in a variety of applications, such as inkjet printing and spray coating.

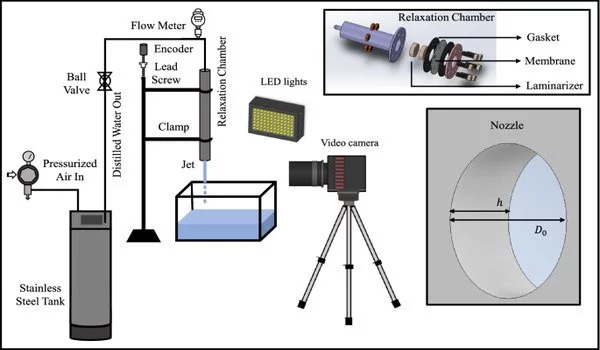

Dickerson’s team developed new equations to account for the interaction between the flow of liquid and the dilation of the elastic nozzle in order to assess the impact of deforming nozzles. They then used a series of simple nozzles to test the accuracy of their mathematics, punching a 0.5 mm hole into different elastic membranes of varying stiffness.

When the researchers squirted liquid through these nozzles, they discovered that the softest, most deformable materials produced the most stable jets over a wide range of flow rates. Their findings provide important information about how to improve the stability of liquid jets, allowing their users to hit their targets more precisely.