Tech has a new perspective and can combine numerous sorts of data that we cannot see: lidar, infrared, ultrasonic, and so on. With its PolarEyes technology, Metalenz, a developer of incredibly tiny “2D” cameras for sophisticated sensing, intends to integrate polarized light into the mix for security and safety. Polarization is not a light quality that gets a lot of attention. It has to do with the direction of the photon’s travel as it waves through the air, and you can usually receive all the information you need from light without examining its polarization. That is not to say it is not useful.

“Polarization is often dismissed, although it can reveal a lot about the materials used in the objects you’re looking at. Metalenz co-founder and CEO Rob Devlin remarked, “It can locate contrast that standard cameras can’t notice.” “It’s been used in healthcare for years to determine whether a cell is cancerous or not – the color and intensity don’t change in visible light, but polarization does.” However, because polarized light cameras almost exclusively used in medical or industrial contexts where their unique properties are required, the machines that perform this function are extremely expensive and enormous.

Even if you could afford the six-figure price, this is not something you would want clipped to the top of your laptop screen. When I wrote about Metalenz last year, their breakthrough was in reliably and affordably manufacturing the complicated micro-scale 3D optical characteristics needed to create a tiny but functional camera on a chip. These devices now developed as part of an industrial 3D sensing module, partly in collaboration with STMicroelectronics, according to Devlin. The polarization issue, on the other hand, has more consumer-relevant implications.

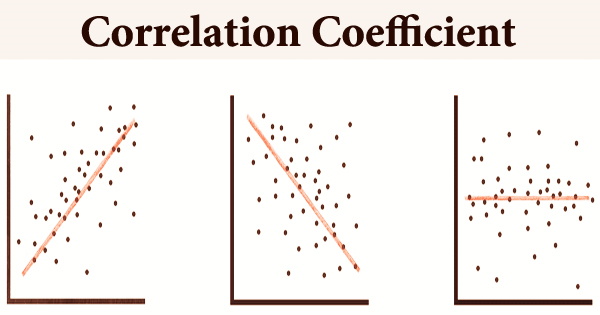

“In facial recognition, polarization tells you whether you’re looking at real human skin, a silicone mask, a high-resolution photo, or something else.”You can identify black ice in automobile conditions; it’s difficult with standard cameras, but it jumps out with polarization,” Devlin explained. In the case of facial recognition, the unit might be small enough to fit with a regular camera in a front-facing array, similar to the lidar unit found in iPhones, which scans the face with tiny lasers. In this case, a polarized light sensor would split the image into four parts, presumably corresponding to four separate polarization axes, each of which displays a slightly different version of the image.

These discrepancies can analyzed in the same way that differences between photos taken at a short distance or time apart may examined, allowing the geometry and details of the face to be observed. Polarized light has the added benefit of allowing you to distinguish between different materials: skin reflects light differently than a realistic mask or photo. Perhaps this is not a common concern in your daily life, but if a phone manufacturer could acquire a similar “Face ID” function with improved anti-spoofing security and utilize something less exotic than a tiny lidar unit utilizes, they would definitely jump at the chance. (Moreover, Metalenz is in touch with the appropriate folks.)

The automotive and industrial sectors are especially useful, as determining, what a given pixel made of is a very difficult task that frequently requires recognizing the product it belongs. However, you can instantaneously tell the difference between varieties of materials using polarization data, which is part of Voyant’s lidar’s value proposition. You do not even need a lot of resolution; one polarized pixel for every hundred normal pixels can provide a lot of information about a scene.

All of this is contingent on Metalenz’s ability to create polarized camera modules that are compact and sensitive enough to use in these conditions. They have scaled down the breadbox-scale cameras used in industry to a cracker-sized camera stack that they have been testing, and they are working on a Skittle-sized camera stack that could added to or swapped out for other cameras in robots, cars, laptops, and even even phones. It is firmly in the research and development “development” phase. Metalenz is now operating on the backs of last year’s A round, which included 3M, Applied Ventures, Intel, TDK, and others, the kind of crowd you’d expect to back a potentially lucrative new component type.