Researchers employ laser treatments to make common cork into an effective tool for repairing oil spills. They experimented with different fast-pulsing laser treatments, closely examining the nanoscopic structural changes and measuring the ratio of oxygen and carbon in the material, changes in the angles with which water and oil contact the surface, and the material’s light wave absorption, reflection, and emission across the spectrum to determine its durability after multiple cycles of warming and cooling. The laser treatments not only improve oil absorption but also aid in keeping water out.

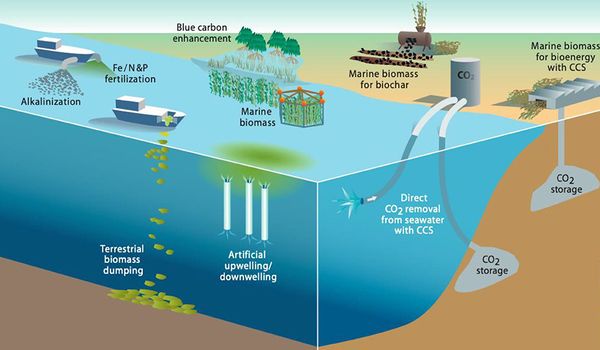

Oil spills are catastrophic calamities for marine environments. They have the potential to have long-term effects on fish and marine mammals, as well as devastate coastal forests, coral reefs, and neighboring land. Chemical dispersants are often used to break down oil, but they often increase toxicity in the process.

AIP Publishing’s Applied Physics Letters describes how researchers from Central South University, Huazhong University of Science and Technology, and Ben-Gurion University of the Negev used laser treatments to transform ordinary cork into a powerful tool for healing oil spills. They aimed to develop a safe, effective oil cleanup solution that used low-carbon materials, but their decision to use cork was influenced by an unexpected discovery.

In a different laser experiment, we accidentally found that the wettability of the cork processed using a laser changed significantly, gaining superhydrophobic (water-repelling) and superoleophilic (oil-attracting) properties.

Yuchun He

“In a different laser experiment, we accidentally found that the wettability of the cork processed using a laser changed significantly, gaining superhydrophobic (water-repelling) and superoleophilic (oil-attracting) properties,” author Yuchun He said. “After appropriately adjusting the processing parameters, the surface of the cork became very dark, which made us realize that it might be an excellent material for photothermal conversion.”

“Combining these results with the eco-friendly, recyclable advantages of cork, we thought of using it for marine oil spill cleanup,” Kai Yin, the author of the study, said. “To our knowledge, no one else has tried using cork for cleaning up marine oil spills.”

Cork is derived from the bark of cork oak trees, which can live for hundreds of years. These trees may be harvested every seven years, making cork a renewable resource. When the bark is removed, the trees increase their biological activity to replace it and store more carbon, therefore harvesting cork helps to reduce carbon emissions.

The scientists experimented with different types of a fast-pulsing laser treatment to find the best balance of qualities in the cork at the lowest possible cost. To determine the material’s durability after multiple cycles of warming and cooling, they closely examined nanoscopic structural changes, measured the ratio of oxygen and carbon in the material, changed the angles with which water and oil contact the surface, and measured the material’s light wave absorption, reflection, and emission across the spectrum.

Cork’s photothermal characteristics are enhanced via laser processing, allowing it to warm up quickly under the sun. The deep grooves also enhance the surface area exposed to sunshine, allowing a small amount of sunlight to warm the cork in 10-15 seconds. This energy is used to heat up spilled oil, lowering its viscosity and making it easier to collect. In experiments, the laser-treated cork collected oil out of water within 2 minutes.

The laser treatments not only improve oil absorption but also aid to keep water out.

“When the cork undergoes a fast-pulsing laser treatment, its surface microstructure becomes rougher,” he explained. “This micro- to nano-level roughness enhances hydrophobicity.”

As a result, the cork accumulates oil without absorbing water, allowing the oil to be removed from the cork and possibly reused.

“Oil recovery is a complex and systematic task, and participating in oil recovery throughout its entire life cycle is our goal,” Yuchun said. He said. “The next step is to prepare electrothermal materials using polyurethane foam as the skeleton for oil adsorption, combining photothermal and electrothermal techniques to form an all-weather oil recovery system.”