Executive Summary

Textile industry plays a very crucial role in the export scenario of Bangladesh. Textile manufacturers produce the raw fabric that is eventually used in producing final garments. There are many fabric manufacturers in Bangladesh, producing many different types of fabrics. In context of 100% Cotton Yarn Dyed shirting fabric, the name of Evince Textiles Ltd. is like a shining star in the sky.

ETL started its operation in 1993 and now it challenges the old and big Y/D fabric manufacturers of Bangladesh. All the big foreign buyers including H&M, C&A, CMT, Tema, Carrefour, Meta, George, M&S have over-booked the monthly capacity of ETL in such manner that ETL now cannot even possess any scope of taking orders from the local buyers.

Such embellishment has occurred only because of maintaining good quality and ultimately keeping the buyers satisfied from all respects. This is what I wanted to study, the relationship between product quality and customer satisfaction of Evince Textiles Ltd. In order to accomplish this job, I have analyzed the market and industry scenario, current condition of ETL, and nevertheless the data I had gotten from the customers of ETL through a useful and resourceful survey.

After the survey I have calculated the frequency distribution of the independent variable and tried find and interpret the data. Then I have provided some very important and useful recommendation which I believe ETL will follow in near future in order to sustain with reputation in the market.

Finally, I have concluded with saying that the product quality of ETL is the main reason for its customer satisfaction. Over here, product quality doesn’t mean the fabric quality only. It contains the over product, price, promotion, delivery, service, and commitment quality of ETL and its human resources.

1.0 Introduction

Since inception in 1983, Evince Group has expanded manifold over the years and today Evince is one of the most diversified and independent manufacturing conglomerates in the Apparel and textile Industry of Bangladesh. In my project part I have tried to relate the current business strategies of Evince with the business theory and tried to learn what they have been doing for decades to be successful. I was very curious about the customer satisfaction of Evince and I wanted to know about the key factors that satisfy their customers. For this reason, I have conducted a survey among the buyers of Evince and based on that data I have done analysis. From that analysis I came to know some factors which led the customers to be satisfied.

1.1 Significance of the Study

This topic is very important for the people who are involved in the textile industry. This project work will help them to understand about the different opportunities and threats and also help them to understand the strategy of Evince Textiles Ltd. In addition to this, There are many people in Bangladesh who are directly or indirectly involved with the Textile industry and their livelihood is dependent on that sector.

1.2 Objective

By doing this project I have understood the business strategy of Evince Textiles Ltd and their marketing strategies. I will have a good understanding about the management and marketing practices of the organization. I have chosen this topic because our economy is very much dependent on textile industry and Evince is one of the largest conglomerates in our textile industry. I want to know their business strategies which will helps me to implement in future. Moreover, by doing this project I will understand the basic difference between local companies and foreign companies. And it will also help me to understand the buyers’ psychology.

1.3 Problem Definition and Hypothesis:

Evince Textiles Ltd is doing business for years and so far they are able to satisfy their customers. But in the new era of business the dimension of customers’ need have changed and their perception as well. In order to defend that situation I need to measure the customers’ satisfaction from different perspective. So I would like to do my project on the business strategy of Evince Textile Ltd. And my hypothesis is

Better product quality of Evince is the key to satisfy its buyer/customer satisfaction.

So, Null Hypothesis, Ho= There is a relationship between product quality of ETL and its customers’ satisfaction

Alternative Hypothesis, H1= There is no relationship between product quality of ETL and its customers’ satisfaction

1.4 Methodology

By taking help of the primary data I will make this research paper more effective. I will collect data from the Evince Textiles LTD and also from different textile manufacturers. And it will help me to understand about the demand and supply of the Textile related products. Moreover, I will be conducting primary research which will be consists of the opinions of different employees who is working in that sector. I will be conducting the primary research through door to door survey, mailed questionnaire, personal interview and group discussion. And my sample size will be 50. And all the respondents are the buyers of Evince Textile Limited.

To make the data meaningful I have done Frequency and graphical presentation etc.

In order to prove the hypothesis I have taken some variables as independent variables.

The list of independent variables is given below:

– Product Quality: Here the perception of the buyers’ toward the product’s quality is justified.

– Product Price: Whether the buyers are satisfied with the price of the product of Evince

– Buyers’ Requirements: Buyer’s requirements has an impact of their satisfaction

– Product Design: It has an impact on buyers’ satisfaction.

– Reliability of Evince: If Evince is not reliable to the buyers the buyers would never be satisfied

1.5 Limitations of the Study

There are some limitations of the study. Time constraint is a big factor here. Because it takes lot of time to make the project more effective and suitable for everyone. Moreover, data availability is another big issue here because company does not want to disclose all the confidential information regarding sales and profits.

Organization Part

2.0 Overview of Evince

2.1 Background

Since inception in 1983 Evince Group has expanded manifold over the years and today Evince is one of the most diversified and independent manufacturing conglomerates in the Apparel and textile Industry of Bangladesh. With the vision and philosophy to partner the customers, Evince has made every effort to involve in all areas of Apparel production like textile, garments, labels, sewing thread, button and other related accessories. Evince Textile Ltd (ETL) is a sister concern of Evince Group and it is one of the giants in the textile industry of Bangladesh. Their main product is 100% Cotton Yarn Dyed shirting fabric. By assuring quality and services ETL has become prominent to the local and foreign buyers. At the moment, ETL’s production capacity is booked with orders up to August, 2010 and all of them are giant foreign buyers including H&M, C&A, CMT, Tema, etc.

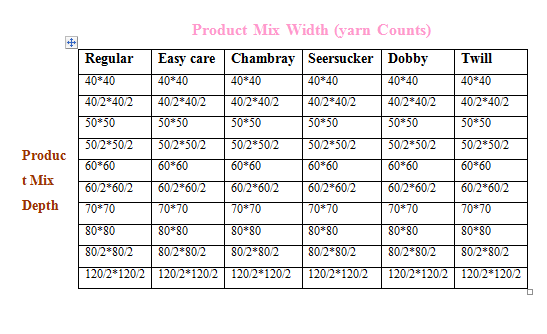

Evince Textiles Ltd. started its in 2003 with a goal for producing world class fabrics in Bangladesh. Currently this factory produces over a million yards of cotton shirting fabrics every month. Our product range contains 100% cotton yarn dyed check and stripe fabrics. Designs include plain, dobby, twills, seer sucker, oxford, solid look, etc. Fabrics are made of a variety of yarn counts like 30’s, 40’s, 50’s, 60’s, 70’s, 40/2’s, 80/2’s, 100/2’s 120/2’s and many more.

2.2 Different Divisions

There are seven sections in textile division. The descriptions of the sections are given below:

Yarn Dyeing:

The current yarn dyeing capacity is around 6000 kg per day. Facility is full equipped with a complete lab for shade matching and color development. The dyeing vessels are the latest models from Tong Geng with computerized control system. The vessel capacity is 5 kg to 400 kg, supported by 400kg pressure dryer for drying. The unique combination of small and large dyeing vessels contributes extreme flexibility while handling variety of order size, large number of colors and different quantity per batch.

Warping:

Swiss made Ben-Tronic new generation sectional wrappers, based on unique technology, optimum ergonomics and high flexibility enabling to process all kinds of yarn dyed patterns.

Sizing

The new Ben Sizetc sizing machines with additional new automatic control undertakes all the functions needed for a perfect warp. Present tolerance limits ensures uniform quality, tensions, stretches temperatures and squeezing pressures etc.

Weaving

The versatility in weaving is one of the major strength of Evince Textile. Our weaving section contains brand new 160 Italian rapier-weaving machines from SOMET, SMIT and VAMATEX. All looms are capable to insert 8 colors in the weft and equipped with Electric Dobby where the number of shafts is as high as twenty. Beside that a number of looms are equipped with double beams in order to handle seersucker and designs with different warp tension.

Finishing:

The in house finishing unit ensures that any fabric that moves out of our factory is best quality product. The finishing plant machineries are carefully selected that are customized to process yarn dyed shirting fabrics. Finishing ranges are equipped to do many kinds of special finishes like Carbon peach, Easy to Iron, nano-care, Anti bacteria finish etc.

Laboratories:

Evince textile contains two separate laboratories. One is pilot for color matching another is the quality control lab to ensure online and finished goods quality.

Clientele:

With this capacity, Evince textile is continuously serving many of the world class brands like H&M, C&A, Marks & Spencer, Celio, Matalan, Tesco, Charles Voogle, Carrefour, Gruppo-coin in Europe and Wrangler in USA. There are some Turkey customers as well including CMT, Tema, Meta, etc.

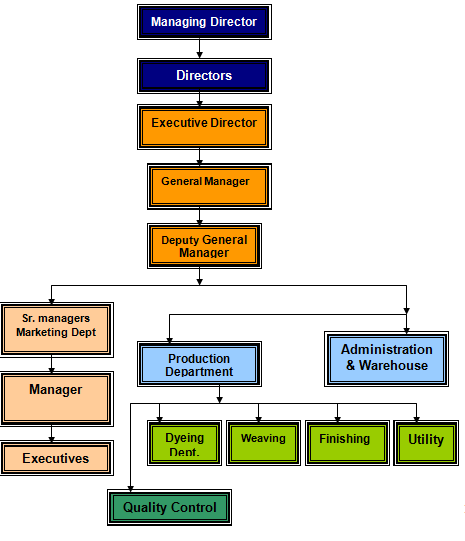

2.3 Organizational Chart

3.0 Current Market Scenario:

The textile industry is very competitive in our country. There are lot of competitors in this industry. In order to clarify the current market scenario I am going to discuss Market Evaluation Model and Porter 5 Forces Model.

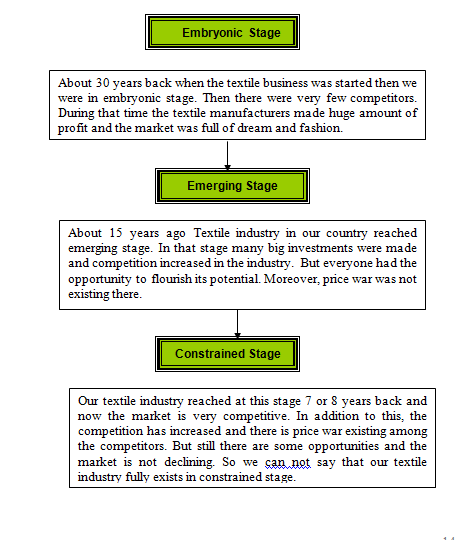

3.1 Market Evaluation Model

By taking help of Evaluation model I am going to discuss about the Textile industry of our country.

3.2 Porters 5 forces

3.2.1 Rivalry among competitors: The market is very competitive. There are lots of competitors in the Textile industry right now. And to some extent the price war also exists among the competitors. But due to higher demand of the product the market is quiet normal. So in the textile industry rivalry among competitors is moderate.

3.2.2 Bargaining power of the buyer: Previously there were very few textile product manufacturers. Foreign buyers got the textile product at a lower price compared to other countries. So earlier the bargaining power of the supplier was low and the foreign buyers did not want to argue too much with the manufacturer. But the current scenario is bit different. Now there is lot of manufacturers and the market is getting competitive. For this reason the bargaining power of the buyer is quite high right now.

3.2.3 Bargaining power of the Supplier: Along with the manufacturers, the demand of our textile and garment product has also increased. For this reason, the bargaining power of the supplier has not fluctuated too much. And the bargaining power of the supplier is moderate here.

3.2.4 Substitute products: Substitute product does not exist in the market and the demand of this product is quite inelastic. So here the threat of the substitute product is very low.

3.2.5 Risk of entry of new firms: Not only are the local investors but also the foreign investors are very much welcome to invest in the textile industry in our country. And the government gives all sorts of facilities to the new investors. And due to higher profitability investors are very much interested to invest in this industry. For this reason the risk of the entry of the new firms is very high.

4.0 SWOT Analysis

4.1 Strength:

ETL has a good relationship with the foreign and local buyers which helps them to make long term profit and it also helps them to reduce promotional and marketing expenditure.They use high quality machineries in their production house which brings efficiency and also reduce the wastage.They have well qualified and well trained marketing department which helps them to achieve their goal.Good coordination among the departments.Evince Textiles Ltd is a sister concern of Evince Group. So they have a good financial background which helps them to face many difficulties.Currently the product demand is so high that some foreign buyers have booked the production capacity for several months. So, ETL now doesn’t have to rely on local buyers to fulfill their capacity.

4.2 Weakness:

Too much workload on the employees that affect on their productivity.Evince textile can produce 700000 yardages of fabric per month. So sometimes they can not fulfill the demand which may have a bad impact in the long term relationships with their buyers They do not have any proper human resource department at their production level. Sometimes ETL is not able to deliver the 100% appropriate products that are ordered by the buyers. And as a result of that buyers are harassed and they become dissatisfied.

4.3 Opportunity:

Low labor cost in our country helps the Textile manufacturer to produce the textile product at a lower cost. As a result of that they can sustain in the long run. Now the whole world is suffering from serious economic catastrophe. As a result of that the purchasing power of the western people goes down. So, the demand of the cheaper garment and textile product has gone up. So it is a great opportunity for ETL to flourish their business. Due to higher labor cost many countries like china, India etc. are not able to compete with the Bangladeshi manufacturers. As a result of that foreign buyers are more interested to do business with our textile manufacturers. Our economy is dependent on the textile and garment industry. We earn most of our foreign currency from this export oriented business. So government has a soft corner for this business and the government is going to take some more initiatives to help this business. As a result of that the textile manufacturer will be more benefited during the recession period.

4.4 Threats

Due to over-booking of production capacity of ETL by a few foreign buyers like H&M, C&A, CMT, Tema, the local buyers are being refused to sell fabrics. It might harm reputation of ETL and local buyers may not issue orders in future if there is less orders from foreign buyers in future. Recent political situation is not favorable at all for the business. The political situation should not be like that specially during the period of serious economic catastrophe.Economic recession of United States and many other European countries going to affect our economy soon. And it results the evaluation of money against the foreign currency like Euro, GBP etc. As a result of that our export oriented businesses earn less foreign currency than before.Due to some political problems labor dissatisfaction has risen in our textile and garments industry which has a bad impact on the mind of foreign buyers.

5.0 Marketing Strategy of Evince Textiles Ltd.

5.1 4P’s of Evince textile LTD

5.1.1 Product:

Evince produces 100% cotton yarn dyed fabrics. Though ETL is a business to business firm, we need to categorize their product in business product classification. ETL does not produce finish product, they only produce the Fabric which is used as a raw materials in finished garment.

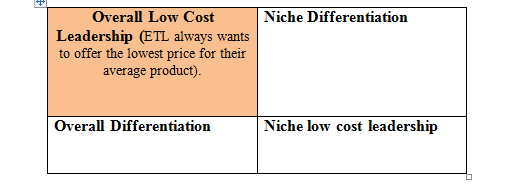

Generic Competitive Strategy:

Product Lines and Product Mix of ETL:

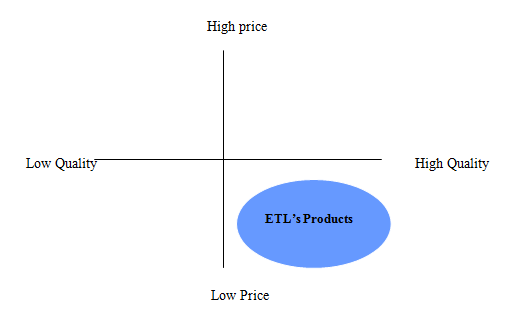

Perception Map of ETL’s product

ETL’s products are higher quality product compared to the other Bangladeshi manufacturers. But the foreign buyers consider our product as cheaper product in finest quality. They consider our products as better quality at a lower price. For this reason ETL’s product exists on the side of “High quality- Low price” in perception map.

ETL has a team of fashion designer and the team is responsible to bring innovation and elegance in their product line. This team design the product based on the current market demand and the current trend. They also forecast the seasonal trend and demand of the clothing and make the design according to their findings.

5.1.2 PRICE

ETL price their product based on the construction of the product. A fabric which has a higher rate of construction, yarn count, and good quality it costs more. For setting the price ETL keep an amount as gross margin then add the cost of the product with the gross margin.

Competitive Pricing: In order to sustain in the market they follow competitive pricing. They set the price based on the price of the competitors. Though the market is getting competitive and ETL is bound to lower the price of their product. In that situation they maximize their revenue by bringing efficiency in their production system.

They also charge higher price for some of their premium product. For example Fil-a-Fil and Chambray are their two premium products and no other Bangladeshi manufacturer is as efficient as ETL to produce those products. For this reason ETL asks higher price for that products.

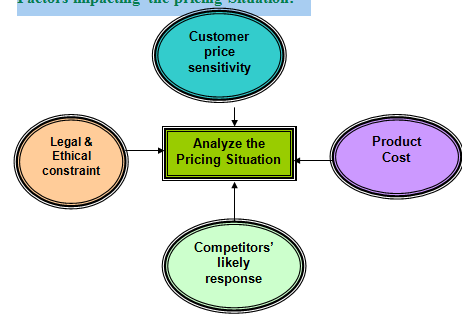

Factors impacting the pricing Situation:

Customer price sensitivity:

Here the customer is price sensitive and due to higher competition among the manufacturers, the customers are in superior position. So price sensitivity of the customers plays a crucial rule here.

Product Cost: Product cost is the other factor here. Product cost influences the pricing situation very much. ETL charge the product price based on the production cost.

Competitors’ likely response: For pricing situation it is also very crucial. If any company asks higher price for any product then the others overlap the situation and offer lower price to the buyers. Competitors respond very aggressively in this situation.

Legal and Ethical Constraint: In our country there is not any legal or ethical constraint for pricing. So the manufacturer does not need to think about the legal issues.

Use of price in Positioning Strategy

Instrument of Competition: ETL uses price as an instrument of competition with their competitors. As I have said earlier, now ETL is one of the largest companies in textile industry. And by producing huge amount of product they gain economies of scale. In addition to this they always try to be efficient in their production system. As a result of that they achieve the quality to lower the price a bit. Eventually, without losing any profit they are now able to use the pricing technique as an instrument of competition.

Quality and Image of the product: ETL asks higher price for some premium products and they have competencies of that product. And no other Bangladeshi company is as expert as ETL to produce that product. The higher price of that product shows the image and quality of that product.

5.1.3 Promotional Strategy:

In their promotional strategies ETL does sales promotion, Public Relations, personal selling, Direct and interactive marketing.

Advertising: For Advertising ETL attends many different fairs in home and abroad. They attend fairs in different countries in Europe and America. They also attend many fairs in Bangladesh that are usually organized by BGMEA. Texworld fair in Europe and BATEXPO in Bangladesh are mainly attended by ETL.

Public Relations: They have very good relationship with most of the local garment manufacturers and they are also very dedicated to keep good relationship with the foreign buyers.

Personal Selling: ETL does personal selling. Their marketing department is responsible to communicate with the buyers. And they always inform the new buyers about their products. Moreover, they always keep in touch to the old buyers and very keen to help the buyers by giving any sort of update and samples regarding their product.

Direct and Interactive marketing: ETL performs direct and interactive marketing. They communicate to different buyers and they arrange formal and informal meetings with them.

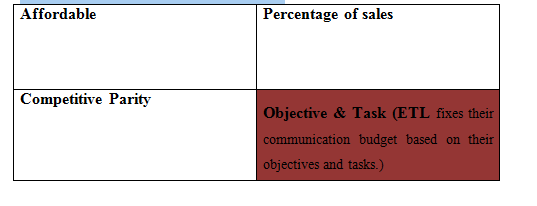

Marketing Communication Budget:

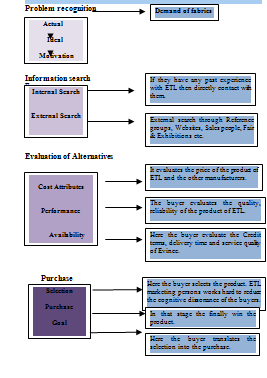

5.2 Classic Decision Making Model of the ETL consumers

6.0 Production Flow Chart:

The sales people of ETL first offer their product to the buyers. If the buyers like the product then the buyers ask for the detail of the fabric and the handloom as well (Handloom is a hand-made sample swatch of Actual fabric). On the other hand, if the buyer has any preference then the buyer sends the sample of the fabric as a handloom or CAD. Then by taking help of the production expert sales people let the buyer know about the actual construction of the fabric and they also suggest the buyer about the best construction for the fabric. After having the acceptance of the buyer, sales people inform the factory about the order and tell them to go for production in a suitable time.

Yarn dying is the first phase in production process. Then the dyed yarns go for warping. After finishing the warping process sizing take place. Then weaving occurs. After finishing the weaving process the fabric is taken for finishing. And now it is ready to deliver the fabric.

Now this is the time to deliver the fabric to buyer. And before giving the delivery ETL needs to send the bulk sample delivery to achieve the buyers’ acceptance. If the buyer agrees with the sample and accept it then ETL will send the total delivery. But if the buyer does not accept the sample then ETL needs to go for reproduction according to the buyer’s instructions. And then they have to again follow the steps from Yarn dyeing process

Analysis Part

7.0 Interpretation & Finding

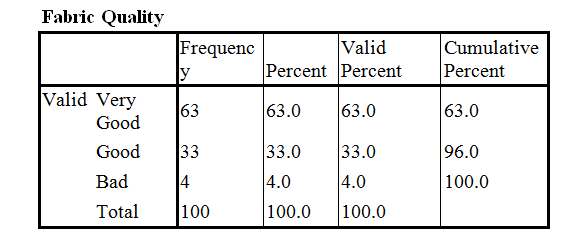

7.1. Fabric Quality:

Interpretation: Here, the respondents were asked to grade the fabric of ETL in terms of quality. Among 100 respondents, 63% respondents said that the ETL fabric is very good in terms of quality. 33% of them said that the fabric is good enough and the rest 4% respondents said badly about the fabric quality of ETL.

Finding: This survey proves that the buyers are mostly satisfied because of the very good quality fabric of ETL.

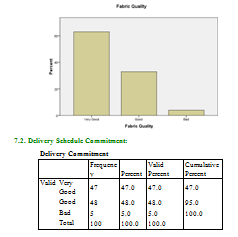

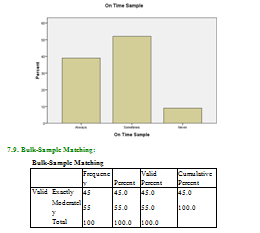

Interpretation: Here, the respondents were asked about the commitment level of ETL in maintaining delivery schedule. Among the 100 respondents, 47% people said that ETL has a very good commitment record in terms of maintaining timely delivery. The highest rate of 48% people said that ETL maintains overall good delivery schedule. Only 5% people had a bad experience with ETL in terms of delivery schedule of bulk goods.

Finding: This survey proves that ETL’s buyers have a satisfactory level of experience with its quality delivery commitment.

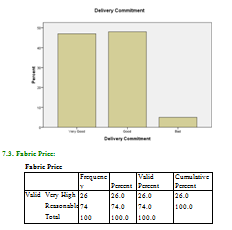

Interpretation: Here, the respondents were asked about their perception regarding the fabric price of ETL. Among 100 buyers, 26% of them said that the price is very high. The rest 74% buyers perceived the price as reasonable. Surprisingly, no one said that the fabric price of ETL is low.

Finding: This survey proves that most of the buyers perceive that the fabric is reasonable considering its fabric quality and they are satisfied with it.

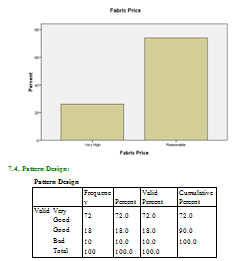

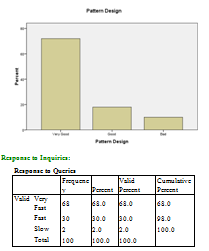

Interpretation: Here, the customers were asked to grade the pattern design of the Y/D fabrics of ETL. Among 100 customers, a high rate of 72% buyers said that their design is very good quality. 18% people said that it is overall good. Only 10% of the customers said badly about the pattern design.

Finding: This survey proves that the pattern design of the ETL fabrics is very good and customers are very satisfied. The designer Mr. Showgato Chakroborty designs all the patterns at his design studio.

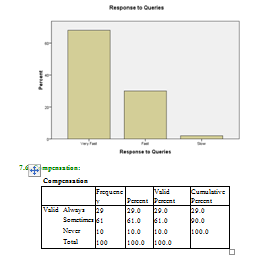

Interpretation: 100 buyers were asked that how fast the sales & marketing personnel of ETL respond to their queries. As high as 68% of them said that they respond very fast and effectively. 30% of them said that they are fast enough. Only 2% of the buyers had a bad experience and said that they respond slowly to their queries.

Finding: This survey proves that the sales & marketing personnel are very efficient in responding to customer queries and customers are also very satisfied with them.

Interpretation: Here, the buyers were asked if ETL provides compensation for any fabric fault or shortage or delay in delivery schedule. Among 100 respondents, 29% people said that they always get compensation whenever there is any fault. 61% of them said they do get compensation but not always. 10% people said that they never get any sort of compensation whatsoever.

Finding: This survey proves that buyers of ETL are more or less happy with the compensation policy of ETL, but not completely satisfies as because they always demand full compensation.

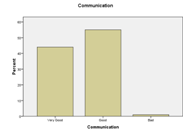

Interpretation: 100 random buyers of ETL wee asked about how well the sales & marketing personnel of ETL communicate with them, via phone, e-mail, or in person. 44% of them responded that their communication proficiency is very good. 55% people commented overall good on their communication process. Only 1% buyer had a bad experience with ETL regarding communication.

Finding: This survey proves that most of the buyers of ETL have a good experience regarding communication with the sales & marketing personnel and buyers are satisfied with it.

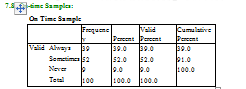

Interpretation: Getting samples on time is very crucial for buyers because they also need to make garment samples on time and present those to their end buyers in order to grab orders.

Among 100 respondents, 39% people said that they always get samples on time from ETL. 52% people said that they sometimes get samples on time, not always. 9% people commented that they never get samples on time, which is a very bad sign.

Finding: This survey tells that buyers are not much happy with the sampling schedule of ETL. So, they need to work on this.

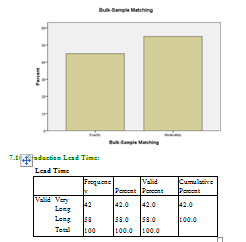

Interpretation: It is very important to look after that final bulk fabric matches exactly with the sample the sample that was provided before taking the order from the buyer. Otherwise the buyer demands compensation for this fabric fault.

Among 100 respondents, 45% people said that the bulk fabrics matches exactly with the sample provided. The rest 55% people said that the bulk matches moderately with the sample fabric, not exactly. Amazingly, no buyers said that the bulk doesn’t match at all with the sample.

Finding: This survey proves that the buyers are more or less satisfied with the matching of sample and bulk fabric.

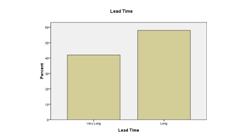

Interpretation: Buyers or customers place orders only if they can agree with the production lead time of ETL because they also have to maintain a certain led time to produce final garments.

Among 100 respondents, 42% people said that the production lead time at ETL is very long. The rest 58% people commented that this lead time is long at ETL. No people said that the lead time is short over here.

Finding: This survey tells that customers are not much happy with the long production lead time of ETL, although they are placing orders because of good quality fabric and reasonable price.

8.0 Recommendations:

From the analyses and findings interpreted above, I would like to recommend the following factors to be taken seriously by ETL management.

- ETL should increase their loom efficiency and install higher quality foreign machineries in order to avoid different types of fabric fault as well as avoid compensations, which incurs huge amount of losses sometimes.

- Currently there is only one designer working at the design studio. A couple of more designers or assistants should be employed so that they can work efficiently in a team and design more lucrative and exact patterns.

- In order to avoid mismatch between samples and bulk, ETL should install fully automated computerized software and machineries because these problems usually arise from errors in manually input data and confusions from those. It is sometimes seen the pantone numbers are incorrect or the sample numbers are incorrect in the labels. So, they should work seriously on this issue.

- Many more looms should be installed in order to avoid minimize the lead time for production. Otherwise the regular buyers will get delivery on time and local irregular buyers will not. Ultimately they will lose interest in ETL and in future if there’s any scarcity of foreign buyers and orders at ETL, those dissatisfied local buyers will not place orders either.

- A couple of more messengers should be employed at the sales & marketing office of ETL so that buyers can get samples promptly and on time. It is very important because if the buyers get sample from other fabric manufacturers quicker than ETL, they might switch from ETL and place orders with other manufacturers.

- Efficiency should be maximized by employing more professional management personnel so that fabric price can be reduced because the yarn prices are increasing on a weekly basis now.

- ETL should buy more cargos and vans of their own so that they can arrange immediate delivery and not wait for rented transport.

- Sales & marketing personnel should communicate well with the local buyers as well as the foreign buyers because no buyer should be seen as small in order to sustain with reputation in the market.

9.0 Conclusion

From the above stated analysis, it can be said that product quality of Evince Textiles Ltd. Plays most significant rule for customer satisfaction. In addition to this, Good co-operation of Evince and Their verities of product also play crucial rule for customer satisfaction.

Further more, to some extent buyers become satisfied when their requirements are fulfilled. Moreover, Buyers also become satisfied when they get good co-operation from Evince Textiles Ltd.

Therefore, definitely product quality plays vital rule for customer satisfaction. But along with the product quality Good co-operations, Product variation and fulfilling buyer’s requirements appropriately plays a crucial rule for customer satisfaction.

If ETL can meet the recommendations above, there will be no other player in the market who could beat ETL in the Y/D shirting fabric industry.

Finally, I can conclude with saying that the product quality of ETL is the main reason for its customer satisfaction. Over here, product quality doesn’t mean the fabric quality only. It contains the over product, price, promotion, delivery, service, and commitment quality of ETL and its human resources.