Induced Gas Flotation (IGF) is a water treatment method that uses gas bubbles to remove suspended particles, oil, and other pollutants from water. IGF is a water treatment method that clarifies wastewaters (or other liquids) by removing suspended particles such as oil or particulates. This technology is widely used in the oil and gas sector to treat generated water, in which water extracted alongside oil and gas must be separated and cleaned before release or reuse.

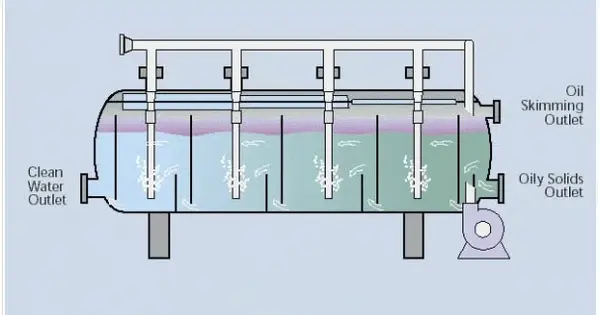

The removal is accomplished by pumping gas bubbles into the water or wastewater in a flotation tank or basin. The little bubbles cling to the suspended stuff, enabling it to float to the surface of the water, where it may be retrieved with a skimming equipment. Due to the risk of explosion, IGF units in the oil industry do not use air as a flotation medium. The bubbles produced by these IGF units are created using natural gas or nitrogen.

Here’s a brief overview of how Induced Gas Flotation works:

- Introduction of Gas: Gas, typically air or another inert gas, is introduced into the water stream. This can be done through mechanical means, such as a pump or a specialized gas-inducing device.

- Formation of Microbubbles: The introduced gas forms small bubbles in the water. These bubbles attach themselves to the suspended particles and oil droplets in the water.

- Buoyancy and Flotation: The attached bubbles reduce the effective density of the particles and oil droplets, making them buoyant. As a result, these buoyant particles rise to the surface of the water.

- Skimming: At the water’s surface, a skimming device or a mechanical scraper is used to collect and remove the floated contaminants. This can be in the form of a surface skimmer or a sloped surface that directs the floated material to a collection point.

- Effluent Discharge: The clarified water, now free of the majority of contaminants, can be discharged or further treated if necessary.

Applications

Induced gas flotation is frequently used to clean industrial wastewater from oil refineries, petrochemical and chemical plants, natural gas processing plants, and other similar facilities. Waste water is also treated using a very similar method known as dissolved air flotation. Mineral ores are routinely processed using froth flotation. In addition, IGF is used to clean wastewater in various sectors.

IGF is especially excellent at removing oil and particles from water streams, and it has several advantages, including high removal efficiency, compact construction, and ease of use. The type of gas utilized, bubble size, residence period, and the parameters of the water being treated can all have an impact on IGF efficiency.