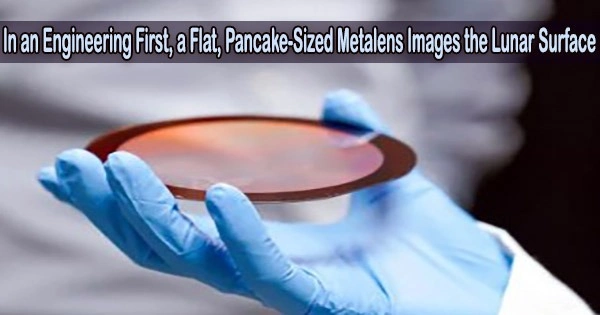

Astronomers and amateur astronomers alike understand that the larger the telescope, the more powerful the imaging capabilities. A Penn State-led research team developed the first ultrathin, small metalens telescope capable of viewing distant objects, including the moon, in order to maintain power while reducing one of the heavier components.

Metalenses are made up of microscopic, antenna-like surface patterns that can focus light to magnify distant objects in the same way that traditional curved glass lenses can, but they are flat.

Though small, millimeter-wide metalenses have previously been constructed, the researchers increased the size of the lens to eight centimeters in diameter, or roughly four inches wide, allowing it to be used in big optical systems like as telescopes. They published their approach in Nano Letters.

“Traditional camera or telescope lenses have a curved surface of varying thickness, where you have a bump in the middle and thinner edges, which causes the lens to be bulky and heavy,” said corresponding author Xingjie Ni, associate professor of electrical engineering and computer science at Penn State. “Metalenses use nano-structures on the lens instead of curvature to contour light, which allows them to lay flat.”

According to Ni, this is one of the reasons why current smartphone camera lenses protrude from the phone’s body: the thickness of the lenses takes up space, even though they appear flat because they are covered behind a glass pane.

Metalenses are often created via electron beam lithography, which involves scanning a focussed stream of electrons onto a piece of glass or other transparent substrate point by point to generate antenna-like patterns. The scanning procedure of the electron beam, on the other hand, restricts the size of the lens that can be constructed because scanning each point takes time and has a poor throughput.

We utilized every possible method to reduce the file size. We identified identical data points and referenced existing ones, gradually reducing the data until we had a usable file to send to the machine for creating the metalens.

Professor Xingjie Ni

To create a bigger lens, the researchers adapted a fabrication method known as deep ultraviolet (DUV) photolithography, which is commonly used to produce computer chips.

“DUV photolithography is a high-throughput and high-yield process that can produce many computer chips within seconds,” Ni said. “We found this to be a good fabrication method for metalenses because it allows for much larger pattern sizes while still maintaining small details, which allows the lens to work effectively.”

The researchers improved on the process by devising their own procedure termed rotating wafer and stitching. The wafer on which the metalens was created was divided into four quadrants, which were then divided into 22 by 22 millimeter sections smaller than a conventional postage stamp.

At Cornell University, they used a DUV lithography equipment to project a design onto one quadrant through projection lenses, which they then rotated 90 degrees and projected again. They repeated the rotation until all four quadrants were patterned.

“The process is cost-effective because the masks containing the pattern data for each quadrant can be reused due to the rotation symmetry of the metalens,” Ni said. “This reduces the manufacturing and environmental costs of the method.”

The digital files necessary to produce the patterns grew much larger as the size of the metalens rose, which would take a long time for the DUV lithography machine to process. To address this issue, the researchers reduced the files by referencing non-unique data and employing data approximations.

“We utilized every possible method to reduce the file size,” Ni said. “We identified identical data points and referenced existing ones, gradually reducing the data until we had a usable file to send to the machine for creating the metalens.”

The researchers created a single-lens telescope using the novel production technology and acquired clear photos of the lunar surface, attaining higher object resolution and a far greater imaging distance than earlier metalenses.

However, before the technique can be used in modern cameras, researchers must address the issue of chromatic aberration, which produces visual distortion and blurriness when different hues of light enter a lens and bend in different directions.

“We are exploring smaller and more sophisticated designs in the visible range, and will compensate for various optical aberrations, including chromatic aberration,” Ni said.

In addition to Ni, coauthors include Lidan Zhang, Shengyuan Chang, Xi Chen, Yimin Ding, Md Tarek Rahman and Yao Duan, all current or former Penn State graduate students in electrical engineering. Mark Stephen, from the NASA-Goddard Space Flight Center, also contributed.

The NASA Early Career Faculty Award, the United States Office of Naval Research and the National Science Foundation supported this work.