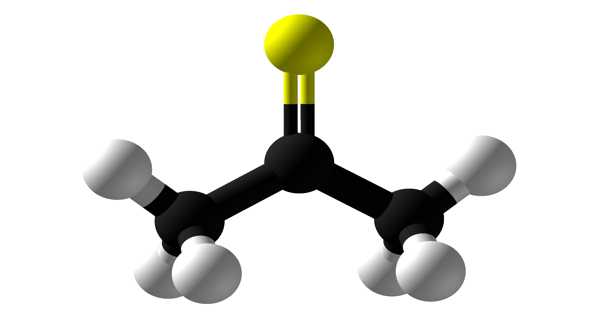

A hybrid silicon laser is a semiconductor laser made of silicon as well as group III-V semiconductor materials. It is a type of laser that generates laser light by combining silicon and other elements. The hybrid silicon laser was created in response to the lack of a silicon laser, allowing for the construction of low-cost, mass-producible silicon optical devices. Silicon is a common material in the semiconductor industry, but it is not a direct bandgap material, which means it cannot emit light efficiently as a laser on its own.

Materials with a direct bandgap, such as gallium arsenide (GaAs) or indium phosphide (InP), on the other hand, are ideal for laser emission. The hybrid technique combines the light-emitting properties of III-V semiconductor materials with silicon’s process maturity to produce electrically powered lasers on a silicon wafer that can be integrated with other silicon photonic devices.

Physics

A hybrid silicon laser is an optical source made of silicon and group III-V semiconductor materials (for example, indium(III) phosphide and gallium(III) arsenide). It is made up of a silicon waveguide bonded to an active, light-emitting III-V epitaxial semiconductor wafer.

The III-V epitaxial wafer is constructed with distinct layers such that the active layer can emit light when activated by either beaming light, such as a laser, or flowing electricity through it. Because of their near proximity (<130 nm), the emitted light from the active layer couples into the silicon waveguide, where it may be steered to reflect off mirrors at the end of the silicon waveguide to form the laser cavity.

By combining silicon with various other materials, hybrid silicon lasers are being created to solve this constraint. The core concept is to design a structure that combines the advantages of silicon’s interoperability with conventional semiconductor production processes with the light-emitting properties of direct bandgap materials.

There are a few different approaches to creating hybrid silicon lasers:

- Bonding Silicon with Other Materials: In this approach, a silicon layer is bonded with a layer of a direct bandgap semiconductor like InP. The silicon layer can act as the waveguide, and the direct bandgap material provides the gain medium for laser light generation.

- Quantum Wells and Dots: Another approach is to create quantum wells or quantum dots of direct bandgap materials within a silicon substrate. These restricted structures may emit light efficiently and are used as the laser’s active zone.

Hybrid silicon lasers are of relevance in photonics and integrated optics because they enable the integration of optical components on silicon devices. This integration is critical for optical communications, optical interconnects in data centers, and other developing technologies. Hybrid silicon lasers offer a possible alternative for efficient, on-chip light sources by combining the electrical and optical capabilities of silicon with the optical emission features of other materials.