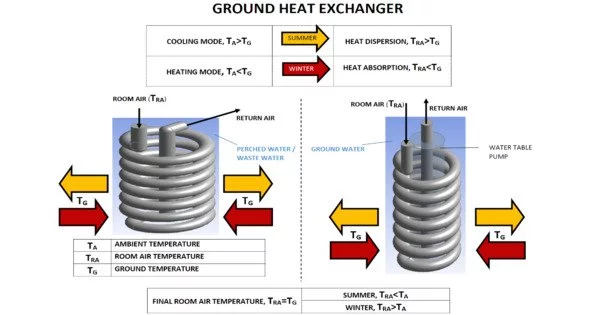

An underground heat exchanger that can capture and/or dissipate heat to the ground is known as a ground-coupled heat exchanger. It is a type of heat exchange system used in residential, commercial, and industrial buildings for heating, cooling, and, in some cases, hot water production.

They use the Earth’s nearly constant subterranean temperature to heat or cool air or other fluids for residential, agricultural, or industrial applications. It exchanges heat with a building’s HVAC (Heating, Ventilation, and Air Conditioning) system by relying on the stable temperature of the earth below the frost line (typically around 5-6 feet or 1.5-2 meters deep). Geothermal heating and cooling systems use this technology.

Here’s how a ground-coupled heat exchanger typically works:

- Heat Exchange Fluid: A closed-loop system circulates a heat exchange fluid, which is typically a mixture of water and antifreeze. This underground loop can be vertical or horizontal depending on the available space and geological conditions.

- Heat Absorption or Rejection: When the building requires heating in the winter, the fluid absorbs heat from the ground, which is relatively stable and warmer than the air in cold climates. When the building requires cooling in the summer, the system rejects heat from the building into the cooler ground.

- Heat Transfer: A heat exchanger or heat pump transfers heat from the circulating fluid to the ground. The heat pump can extract heat from the fluid (to heat it) or reject heat into the fluid (to cool it).

If building air is blown through the heat exchanger for heat recovery ventilation, they are called earth tubes (or Canadian well, Provençal well, Solar chimney, also termed earth cooling tubes, earth warming tubes, earth-air heat exchangers (EAHE or EAHX), air-to-soil heat exchanger, earth channels, earth canals, earth-air tunnel systems, ground tube heat exchanger, hypocausts, subsoil heat exchangers, thermal labyrinths, underground air pipes, and others).

There are two primary types of ground-coupled heat exchangers:

- Horizontal Loop: In this configuration, pipes are buried horizontally in trenches. It’s suitable for locations with ample land area but may require more trenching.

- Vertical Loop: In this configuration, pipes are installed vertically in boreholes, which go deep into the ground. This is often used when space is limited or when the soil quality is not suitable for horizontal loops.

Because there are no compressors, chemicals, or burners required to move the air, earth tubes are often a viable and cost-effective alternative or supplement to traditional central heating or air conditioning systems. These are used to partially or completely cool and/or heat facility ventilation air. Their use can assist buildings in meeting Passive House or LEED certification requirements.

Benefits of Ground-Coupled Heat Exchangers:

- Energy Efficiency: They are highly energy-efficient, as they take advantage of the stable ground temperature to heat or cool a building.

- Environmental Friendliness: They have a lower environmental impact compared to traditional HVAC systems, as they use renewable energy from the earth.

- Cost Savings: Over time, they can result in lower energy bills and reduced maintenance costs.