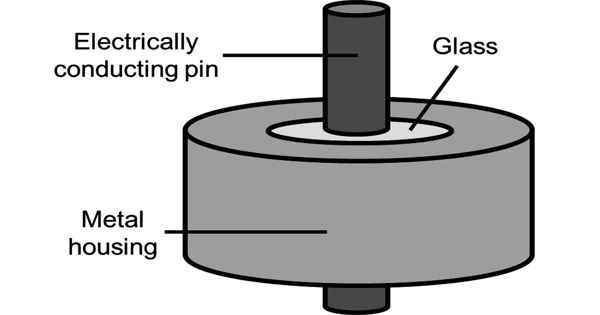

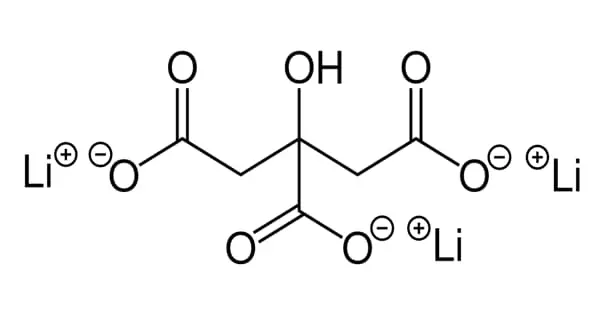

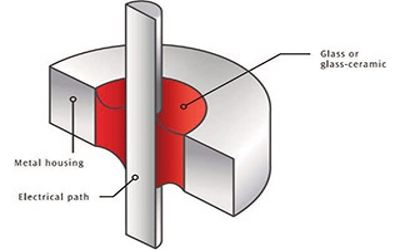

Glass-to-metal seals have been around for many years, with one of the most common uses being lamp bulb seals. Glass‐ceramics are widely utilized in the electronics industry to provide electrical insulation and to form leak‐tight joints with a range of metals. A more recent invention is glass-ceramic-to-metal seals. Silicate‐based glasses are commonly used in conjunction with a stainless steel housing and pins.

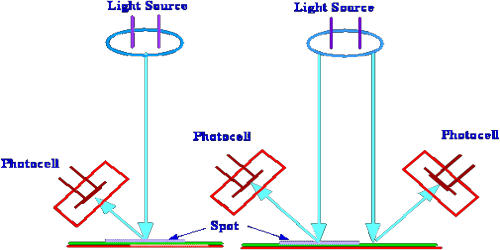

The key function of glass-to-metal seals is to reliably enable the pass-through of electrical or optical signals into vacuum-tight housings or enclosures. These seals are engineered to perform reliably in harsh operating conditions, such as extreme temperatures, moisture, pressure, or chemicals.

Properties

Glasses can be bonded to metals to form hermetic seals for use in a variety of applications. Glass-ceramics are polycrystalline ceramic materials prepared by the controlled crystallization of suitable glasses, normally silicates. The highest performance electrical seal systems employ ceramics for exceptional resistance to thermal and mechanical shock, as well as corrosion. Depending on the starting glass composition and the heat-treatment schedule adopted, glass-ceramics can be prepared with tailored thermal expansion characteristics. Ceramic functions as an excellent electrical insulator at very high temperatures, unlike glass, which conducts more electricity at elevated temperatures.

Ceramic-to-metal seals not only remain stable at extremely high and low temperatures, but they are able to withstand severe thermal shock and repeated thermal cycling. This makes them ideal for sealing to a variety of different metals, ranging from low expansion tungsten (W) or molybdenum (Mo) to high expansion stainless steels and nickel-based superalloys. The ceramic material is typically more expensive than glass and ceramic-to-metal seals require more sophisticated engineering and more complex manufacturing processes.

Ceramic-to-metal seals have a number of properties that allow for a more robust, durable hermetic seal and better electrical insulation than glass-to-metal seals. Glass-ceramic-to-metal seals offer superior properties over their glass equivalents including more refractory behavior, in addition to their ability to seal successfully to many different metals and alloys.

Advantages and uses

They have been used in electrical feed-through seals for such applications as vacuum interrupter envelopes and pyrotechnic actuators, in addition to many applications where a higher temperature capability than is possible with glass-to-metal seals is required, including solid oxide fuel cells. For more demanding applications, glass seals are effective in preventing leakage during severe changes in temperature, pressure and humidity. Another advantage of ceramic-to-metal seals is their high mechanical strength.

Disadvantages

- unable to cope with large CTE mismatches

- precise control of glass composition is required

- controlled recrystallization of glasses is critical.

Information Source: