Gasket Replacement project of Mir Trading Company

Chevron is a large employer in Bangladesh and supplies a large amount of the country’s natural gas consumption. Chevron’s production and exploration projects are continuing to expand throughout the country.

Chevron values integrity, trust, diversity and ingenuity as a company and in its employees. Depending on our role, our journey at Chevron takes us to one or more of the following locations in Bangladesh. Chevron’s compensation and benefits programs are highly competitive within the local labor markets. They are reviewed annually to ensure they meet the needs of employees living in Bangladesh.

This report explains in brief about the work done in gasket replacement project and it has some attachments of pipeline and instrumentation diagram. It shows exactly the flanges where we have worked to replace the existing gaskets with inner ring IR type SWG gaskets.

In this report I have tried to give an overview of the whole work done in this project which continued for four months and I have highlighted the necessary steps of the working process that was carried out to ensure safety and complete the job.

This report also contains a profile of the entire crew members, the scope of work and the flow diagram of the gasket replacement process; it also contains an overview of Mir Trading Company and the job which I had to carry out as a supervisor of this project.

It says about my learning and knowledge that I have gathered throughout this entire journey of the project and the safety culture that I have acquired while working in Chevron premises. It also shows how Mir Trading Company is doing business and earning above average returns and how I had to blend my technical and managerial knowhow to successfully complete the project.

I have tried to portrait my internship program through this report which includes how I had to carry out different managerial functions to complete the job task and attain the desired goal.

Finally, it says about my findings and recommendations for Mir Trading Company which I think they should consider enhancing business performance and increasing the employee productivity as well as reducing employee turnover.

Introduction

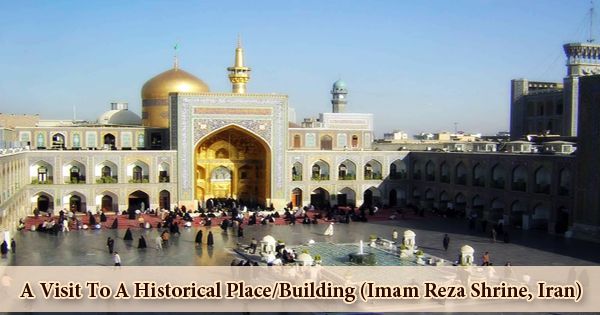

Working for Chevron Bangladesh for four months in Bibiyana Gas Plant and being a contracted employee of Chevron has been a wonderful and challenging experience for me.

This has been possible because I have been working as a contracted employee for more than a year. Initially I was employed by MIR Trading Company in Dhaka Chevron Project where I gained experience as an engineer and then I was offered a permanent position at Bibiyana Gas Plant right after completion of Dhaka Chevron Project and Dehy Reboiler

Chemical Cleaning work during June 2013, but, I had to turn down that offer as I was pursuing MBA in BRAC University. When I nearly completed all the credit courses of MBA in BRAC University luckily I have been offered by MIR to work in a project called Gasket Replacement Project which served as my internship program and I got to earn a valuable experience and knew about job life in a greater perspective.

Internship program is essential for the fulfillment of MBA degree from BRAC University and the purpose of this 4 months internship is to give the students a real life experience of the job field so that they can get a better understanding about the work life and have a bright successful career path.

Background

Internship is required for the partial fulfillment of the MBA degree and hence I had to take the internship program though I have working experience. When I applied for the internship program in MIR Trading Company I had to face an interview and I was asked this question that ‘’ you are already experienced then why are you applying for the internship program?’’ Well I had to reply the manager saying that though I am experienced but my experience is so far in purely technical engineering field and MBA from BRAC University requires experience in business field. Therefore the senior manager assigned me an internship supervisor from the organization and I was given a huge responsibility of onsite Supervisor Engineer. In the course of internship program I had to carry out lots of management functions and finally I can say that now I have the lower level managerial experience of managing 23 technicians working onsite.

Objective

The objective of this report is to portray the work which I carried out in order to complete the internship program and also to be specific it is the requirement to complete the MBA degree.

The Organization

MIR Trading Company was established in 1986, and was represented since then Petbow Generators, UK – one of the most premier diesel generator brands in UK since 1928 and was having subsidiaries in Singapore, France, and Australia. After taking over by Cummins Power Generations worldwide facilities in late 1990’s by Cummins then MIR worked for Cummins Power Generation till 2009. After leaving Cummins in 2009, MIR has entered a new distributorship agreement with Dale Power Solution UK who is also having 75 years in Genset business with 5 times Queens Award recipient. With over 1450 clients all over Bangladesh. MIR provides solution for:

- Turn-key solution of Gas and Liquid fueled Gas Turbine Power Plants from 40MW to 300MW up to 230kV distribution voltage in 50% efficiency Simple cycle, and almost 60% efficiency Combined Cycle on-land or on-barge from USA.

- Dale Power Solution Industrial Genset from 30kVA to 3000kVA Prime rated and also turnkey solution up to 50MW captive power plant to 11kV Generation Voltage.

- Marine Propulsion Engines from 50BHP to 2547BHP from UK and USA made by Cummins.

- Marine Generators from 10kW to 920kW from UK with Cummins/Perkins/Volvo Engine.

- BETA MARINE UK, tailored made Marine Generators with switchgears from 10KVA to 900KVA with marine classification approved in Heat Exchange Cooling, Keel Cooling, and Air, Radiator Type Cooling.

- BETA Marine engines from 10BHP to 120BHP in any Marine application.

- Spare parts for any Cummins engines which include engines, Alternator, and control parts.

- MIR PREMIER OIL Multi Grade Engine Oil 15W40 formulated in USA.

The population of Cummins Engines in Bangladesh is over 3400 and these engines range from 30BHP to 3200BHP in applications of Industrial Generating sets, Marine Gensets, Marine Propulsion, Construction, Automotive, and many other sectors. The large fleet users of Mir’s products include Bangladesh Government, Bangladesh Bank, Warid Telecom, Ericsson, CITYCELL, WASA (Water and Sewerage Authority), Nassa Group, Opex-Sinha Group, Transcom Group , Standard Chartered Bank, EXIM Bank, City Bank, and many others like Bangladesh Army, Air Force, Navy and BDR (Bangladesh Rifles). Some prestigious fleet customers include World Bank, Bashundhara City, Radisson Hotel, Westin Hotel, Chevron, Unocal, Chittagong Port Authority, Ananda Shipyard, Karnafuly Shipyard, Sea Resource, Peninsula Fishing, Paradise Fishing, and most of the hospitals including ICDDRB and most of the Banks.

Along with generator business MIR also works as a contractor of Chevron Bangladesh supplying manpower on a contractual basis for last 4 years and has also started business with Schneider Electric Company as the distributor of their electrical products ranging from electrical distribution boards and panels to circuit breakers and switch sockets.

Service offerings

As a former representative of Petbow Generators, UK, Cummins Power Generation UK, Singapore and Cummins Inc. in Bangladesh and now Dale Power Solution UK for the past 26 years, MIR has invested significantly on after sales services which include trained professionals, 50,000 sqft workshop in Ashulia, Dhaka, field service vehicles and spare parts division. A specially designed building of approximately 5 x 9,000 square feet houses the Service Workshop and Parts Storage.

Repair & Maintenance

The Service Workshop is equipped with the latest in diesel engine repair tooling to service all models of Cummins Diesel Engines. These include special tooling for the overhaul of Cummins Diesel Engines. The Technical Staff have undergone factory training and are capable of carrying out all types of repairs including engine overhauls and maintenance to Cummins Diesel Engines, Stamford Alternators and generating sets..

Field Service

MIR has service Engineers & technicians and are provided with field service vehicles, which are equipped with maintenance tools to carry out repairs on site. Senior Engineers are also contactable on mobile telephones. Emergency assistance is available at all times through a contact number from the workshop and office.

Spare Parts

MIR is the foremost company who stocks highest genuine Spare Parts in Bangladesh to support over 3400 Cummins engines & even other brand of Engines. We have approximately 80% availability of fast moving spare parts in Bangladesh. The Singapore & UK parts distribution centre has 98% availability of vital and fast moving spares off the shelf. Any emergency spares that are not available ex-stock can be Air freighted from UK or Singapore within 3 working days.

Main Alternator

All MIR Supplied generating sets are fitted with a Stamford Alternators manufactured by Newage Stamford of United Kingdom. Now All Dale Power Solution UK made Genset using Cummins Engine & Newage Stamford Alternators with Deep sea control panel. Mir maintained huge stock of Deep Sea Controller for all brand of Genset Control Panel & Battery Charger. The main alternator & exciter insulation systems are impregnated for severe environments where sand, salt, sea spray, and chemical corrosion are installation factors. 125 degrees C temperature rise and Class H insulation system is also provided as standard.

Supply of Equipment

MIR TRADING COMPANY has supplied a range of Industrial Diesel Generating sets from 27 KVA up to 2250 KVA, and Marine Propulsion engines from 180 BHP to 850 BHP to the local industry.

A Genset customer list showing Generating sets that have already been commissioned or are being installed at present can be forwarded to you upon request. MIR maintained huge stock of Diesel Generating set ranging from 35KVA to 750KVA for quick delivery and can meet up any forward delivery upto 3000KVA Genset.

Training and Development

A fully equipped training facility is equipped with real time fault investigation, state of the art simulators for engine fault diagnosis and multimedia presentation for training and development of the technical staff. This training facility is maintained and operated by graduate engineers. This facility is also available to the customers upon request. MIR TRADING COMPANY has the methodological ability and experience to carry out the Supply, Installation & Commissioning of Generating Sets and Marine propulsion engines. MIR also has over USD 200,000.00 worth of testing, commissioning, and other tools for after sales support.

Services offered to Chevron Bangladesh

As a contractor of Chevron Bangladesh MIR nearly has 100 employees working for Chevron Bangladesh on a contractual basis. Apart from manpower supply MIR also supplies Chevron Bangladesh with various electrical products and after sales services of those products. MIR has various projects ongoing with Chevron Bangladesh where MIR Trading provides manpower, technical and expert solutions and Gasket Replacement work was one of those projects.

SWOT Analysis

Strengths

MIR has a fleet of dedicated Engineers who are working relentlessly to make sure that MIR can reach the desired vision. MIR values each and every employees contribution towards the fulfillment of the designated job assigned to them. Being a local company it has a very unique pay structure that ensures employee retention. MIR is the only local company as far as I know which pays 100% bonus on the gross salary of its employees during two EID festivals. The organization believes that the asset of the organization is its employees and hence each and every employee’s contribution is closely monitored and appreciated. The training and development team of MIR Trading company is unmatched where engineers and technicians are given hands on training to perform jobs like maintenance and troubleshooting of its products.

In MIR trading company each and every employee gets a fair chance to learn and grow and build a career according to their aspiration in the electro-mechanical service sector.

Weaknesses

According to me there are many weaknesses inside the operational module of the organization. Firstly the organogram of the company is not clearly defined. There is only one senior level manager to manage all of its employees. MIR does not follow proper recruitment process and in many cases MIR never gives its employees an appointment letter which helps in overnight hiring and firing of employees from the employer’s perspective. MIR does not have any HR department which I believe is their greatest weakness.

Opportunities

According to the life cycle of this organization MIR is still on the growing stage and it is still expanding its operation in power sector as well as in electrical service sector. Throughout the expansion period of the company there are lots of opportunities that I have picked out which can help the company to reach its desired vision. The first opportunity for MIR is that it can restructure the company organogram and create various departments like Sales, Marketing, Finance, HR, IT etc. MIR is currently running with only one department which is Admin and that is controlled by the CEO and owner. The accounts of MIR trading company are closely monitored by the company owner and the internal environment of the company is just like a one man show company. So there is an opportunity of change for MIR Trading to become much more structured and start enterprise resource planning and forecasting. Considering the business of MIR with Chevron Bangladesh it has an opportunity to build a long term business relationship by providing world class service as per Chevron expectations. Also the recent business with Schneider Electrics is a door to opportunities for MIR Trading company as Schneider is a renowned MNC and new in Bangladesh with its operation MIR has the advantage of being the pioneer in being the sole distributor and supplier of Schneider products.

Threats

We are on the age of global integration where each and every country gets affected by global movement of political forces. Hence each and every business gets affected. First and the foremost threat is always the external environment of the business and its competitors. The business which MIR has been doing with Chevron Bangladesh is a lucrative one hence competition is inevitable. Energypac is one such competitor of MIR Trading Company which has recently started participating in all the tendering process for the contracts which MIR has been getting since last four years. Compared to MIR Trading Company Energypac is a giant company which is a real threat for Business. Also there are other companies trying to get the contracts of manpower supply and technical support to Chevron Bangladesh. In order to carry out the business effectively and efficiently MIR needs to scan the internal and external business environment continuously and improve its business processes to cope up with the dynamic market conditions of Bangladesh. Otherwise giant companies like Energypac can drive MIR Trading Company and throw them out of business.

The Project background and objective

The reason for this project initiation emerged after the root cause analysis of the flange leakage which occurred in the year 2012 in BYGP during summer. Chevron investigated and identified that the existing gasket used in the pipe line was not inner ring type SWG gasket hence the leakage occurred due to material degradation of that existing gasket.

As it could not withstand the pressure inside the pipeline hence the gasket broke down and damage occurred at the location site of BYGP. During that time several locations in the entire country did not have the proper supply of natural gas which was supposed to be supplied from Bibiyana Gas Plant.

MIR as a contractor company of Chevron Bangladesh had previous experience of Reboiler Dehy Chemical Cleaning Project which was a pure mechanical job hence; automatically the first preference of the Gasket Replacement Project went to MIR Trading Company.

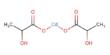

The main work done in this project was replacing the existing gaskets of the pipelines of the Contact tower and High Pressure Separator Systems with inner ring type spiral wound gaskets (SWG).

This gasket replacement was done to make sure that flange leakage does not occur again because in high pressure gas pipelines if any kind of leakage occurs then Chevron and Bangladesh incurs heavy loss. If production stops for an hour we incur a loss of millions of USD/ Taka. Chevron always takes necessary steps to prevent any kind of loss that may arise hence Chevron decided that prevention is better than cure in this kind of scenario.

In Bibiyana Gas Plant MIR Trading has replaced more than a 1000 gaskets and this kind of job can only be done during the plant is shutdown. There are in total 5 trains of Contact Tower and High Pressure Separator systems which are connected to the well head of Bibiyana Gas plant. While MIR worked on one train other trains were online starting from train two we completed a four trains one after another and as other trains were online our job was even more risky and dangerous but we managed to complete the job successfully without any incident.

Planning

Planning is the process of thinking about and organizing the activities required to achieve a desired goal. Planning has a specific process and is necessary for multiple occupations particularly in fields such as management, business, engineering etc. In each field there are different types of plans that help companies achieve efficiency and effectiveness. Planning holds a relationship to forecasting. Forecasting can be described as foreseeing what the future will look like, whereas planning predicts what the future should look like for multiple scenarios. Planning combines forecasting with preparation of scenarios and how to react to them.

Main characteristics of planning in organizations are:

Planning increases the efficiency of an organization. It reduces the risks involved in modern business activities. It facilitates efficient use of the available time and resources. The concept of planning is to identify what the organization wants to do by using the four questions which are

“where are we today in terms of our business or strategy planning? Where are we going? Where do we want to go? How are we going to get there?”

Well in my case during this project I had to plan on every single day about how I will complete my designated task and reach my goal while maintaining safety and all the rules and regulations.

My working shift was 6am to 6pm where I had to complete a specific number of jobs. For a single day I had planned to replace and install in total 25 IR type SWG gaskets ranging from ¾ inch diameter up to 24 inches.

So I had to plan and fix at which flanges and studs I will work on, what tools and equipments I will need, how I will arrange them, which set of workers I will deploy to carry out those tasks and what will be the time frame for every specific task.

In planning phase I also carried out the hazard analysis for every specific task. For example working in ground level and working at heights has different hazards. I had to plan differently while working in confined space and inadequate lighting. I had to plan what kind of personal protective equipments my workers would need and had how I will carry out on-site supervising task while maintaining all the documentation work. Without proper planning I would not have been able to complete the project on time which would hold me liable for huge production loss of natural gas from Bibiyana Gas Plant.

Organizing

Organizing is the process of grouping together of men and establishing relationships among them, defining the authority and responsibility of personnel by using the company’s given authority and other basic resources to attain predetermined goals or objectives.

Once I had completed the planning phase of my work it was time to organize. My ultimate goal was to complete the project on time but for reaching that goal I had to subdivide my tasks into short mini goals. Every single day I had a specific goal of completing a specific number of jobs so that I could complete the total task within the given time frame.

As I had 17 men on board including me during my duty roaster I could easily sub divide 16 men in two groups. Each group then had 8 workers. From those 8 workers in each group I selected one team leader who would lead the job tasks. Usually the team leaders were those experienced technicians who had the technical knowledge and experience of working in Chevron facility.

Our work simultaneously used to start at two locations:

- Contact Tower > Group A(containing 8 technicians including 1 team leader)

- HP separator Area> Group B(containing 8 technicians including 1 team leader)

While organizing the workers I encountered that I actually exercised and exhibited some skills, those are technical, human and very little conceptual skills.

Technical Skill

After planning phase I had to develop my workers with the specific mechanical training and knowledge on mechanical and power tools and its usage. I had to show my workers exactly how to hold the spanner while unbolting the studs, teach them how to work ergonomically without stressing themselves. The importance of designated torque application and star or square pattern marking and so on. I had to prove my eligibility of holding the supervisory post during the tenure of this project for which I worked both physically and mentally to exhibit my technical skills required for gasket replacement work.

Human Skill

Effective managers are able to work well with people, using the human skills essential to successfully lead. The communication and relationship building skills are known as human skill.

In order to maximize the workers output I had to communicate with them properly I had to build a relationship with them a bonding which made them drive to reach their goals so as to attain the organizational goal. Communication skill is the most important skill as per my understanding effective communication reduces human effort and increases the efficiency of the workers in return increasing the efficiency of the work team. My human skills made it possible for me to be able to create an environment where my workers felt comfortable and could open up to me regarding their deficiency of knowledge and skills.

Conceptual Skill

Conceptual skills allow a manager to visualize the entire organization and work with ideas and the relationships between abstract concepts. In my case I did not have to foresee what is going to happen next after this project as I am only a lower level manager. But sometimes I had to make my workers realize that they are working in a prestigious project which has a very high potential to take them further in their careers. Explaining them that the experience that they are gathering and the certification from Chevron Bangladesh that they will be getting after project completion will surely benefit them in many ways and how they will be getting benefited in future regarding other aspects of the job required exhibition of a little bit of conceptual skills for me.

Leading

Leading a large group of 16 technicians requires different approaches of leadership styles. Keeping all of your workers motivated to reach the organizational goal is not an easy task and for which I had to concentrate in few points all the times.

- connect activities to goals

- manage compliance

- engage and motivate workforces by rewarding their performance

As a leader my leadership pattern was much more like an Autocratic leader.

Autocratic leadership

The authoritarian leadership style or autocratic leader keeps strict, close control over followers by keeping close regulation of policies and procedures given to followers. To keep main emphasis on the distinction of the authoritarian leader and their followers, these types of leaders make sure to only create a distinct professional relationship. Direct supervision is what they believe is the key in maintaining a successful environment and follower ship. In fear of followers being unproductive, authoritarian leaders keep close supervision and feel this is necessary in order for anything to be done. Authoritarian leadership styles often follow the vision of those that are in control, and may not necessarily be compatible with those that are being led. Authoritarian leaders have a focus on efficiency, as other styles, such as a democratic style, may be seen as a hindrance on progress.

Bringing out a single example from my working days in BYGP. After completion of Train 2 Chevron officials told me to do the house keeping of the maintenance shop and the generator room of BYGP because we were one day ahead from the work plan so we did not have any specific work of gasket replacement on that day. So I told my workers to start the housekeeping of the shop first so that it gets done before lunch and then they could do the housekeeping of the generator room afterwards. After that I was not in the work site for 15 minutes and when I returned I saw that they were not willing to sweep the floor of the maintenance shop as it was not specified in their contract. They were telling each other that we are mechanical technician we are not supposed to do this kind of job.

So I took the sweeping mop and started sweeping the floor all by myself in front of the Chevron officials , once I started doing that each and every workers got the mental drive which was needed to make them do all the odd jobs of housekeeping.

I would like to exemplify another situation, every day after lunch during 3:00 pm my team used to take an unofficial tea break for 30 minutes which was given by my back to back supervisor and hence after my first rotation of duty when I returned back to work and I allowed my technicians to take the break respecting the decision of my colleague. One day during this break time I got a complaint from the Chevron officials that my workers does not maintain proper hygiene during handling the tea kettles and they normally makes the washroom of the mechanical shop too dirty for others to use it. Soon after getting this complain I called upon my workers for a meeting and told everyone that from now on no one is allowed to have any tea break after lunch break and if they have to use the washroom then they will have to go to some other washroom but not the mechanical shop’s washroom. During the meeting one of my worker started arguing saying that tea is necessary otherwise he will not be able to work and so I had to suspend him for two days from work. Seeing the consequences of arguing with me all other workers became extremely obedient and followed the exact direction that I gave. So I believe that I established pure professional relationship with my followers and I was totally focusing on productivity and efficiency and I could drive my team by being a strict autocratic leader.

Controlling

The controlling process is simply a set of steps a manager uses to determine whether organizational goals have been met. As the supervisor I concentrated on few things which led me to the proper evaluation of the job of my technicians and rectified myself where there was an opportunity to improve.

The controlling process involved:

- Establishing standards to measure performance

- Measuring actual performance

- Comparing performance with the standard

- Taking corrective action

In overall controlling process I followed few steps which made me realize where my team was lagging behind and what kind of initiative I need to take to enrich my team in terms of knowledge skill and attitude and perform to the expectation of Chevron. I tried to get feedback of my work from my superior and also the Chevron officials with whom and for whom we were working relentlessly.

After the feedback survey I got to know that few of my technicians needed extensive training and development because after working for a month many of them still did not know the basic steps of gasket replacement work.

I tried to take a 360 degree feedback about my team from Chevron and my team members which helped me to comprehend my lacking and find out the improvement opportunities. After the 2nd month of this project I reviewed the performance of my technicians using a KPI rating system which was provided from the Dhaka office of Mir Trading Company. Where I marked my technicians on a scale of 5 which had many key performance indicators.

During the last month of this project I was satisfied with the performance of my team as their learning curve rose up to my expectation and it was satisfying because I mostly got positive comments about my team and their working principles and ethics.

Finally Chevron awarded us with certificates of appreciation due to our hard work and challenging job that we completed without any injury or incident.

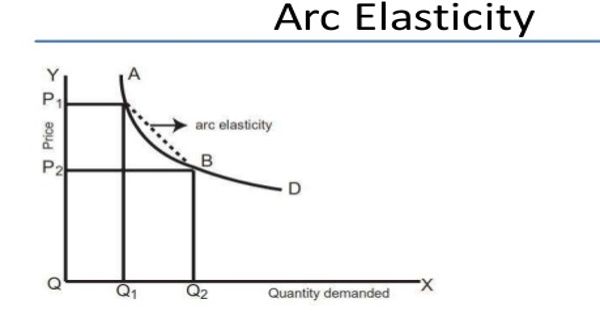

Hypothetical Calculation of Earnings from the Project

Calculating the revenue earned in this project has a very simple formula

Revenue= Total Man-hours x charge per unit.

Let me consider a flat rate of BDT 1,000 (per man-hour)

In this project MIR Trading Company Charged Chevron on the Charge code of BY-OP-00. And MIR charged Chevron showing that all the technicians are expert technician (level III) and the supervisors are highly experienced so actually the flate rate that I have quoted is not the exact figure the exact figure is much more lucrative than the flat rate.

Calculation that I am showing is not accurate but a hypothetical one.

In this project we completed exactly 19,391 man-hour over a period of 4 months and as I have prepared the time sheets of all my workers I knew the exact figure of man-hours.

Therefore,

Revenue= 19,391 X 1,000 = 1,93,91,000.00 (BDT)

Expenses in this project regarding logistic support , food, wages and miscellaneous costing in total may range up to 33,00,000 (BDT)

Therefore a rough estimate of this project profit is 1,60,91,000.00 BDT.

Conclusion

This project of gasket change has been a big challenge for me and I have taken this challenge to complete the project successfully without any incident. It has been a huge honor for me that I was given this opportunity and I feel proud of myself that I could complete this job within the estimated time limit without any kind of problem or injury.

The operations and mechanical maintenance team of Chevron Bangladesh has provided me with the necessary support to complete this job task. For the first time in Bibiyana Gas Plant this kind of huge maintenance and shutdown job has been done. My dedicated team of gasket project has worked with their full dedication to always maintain all the tenets of operation in the work place to ensure safe work practices and procedures.

I have learned lots of things during this project and I feel confident regarding this kind of job in future. The knowledge level of my team has been enriched and the skill of my crews has increased to an appreciable level.

After successful completion of this project I return home with huge experience and I feel confident about myself after realizing my true potential. In future if I am given this kind of job then I know and believe that I will be able to do it even more efficiently and effectively without any incident or near miss.

The safety culture that I have learnt during the tenure of this project will help me through my entire life and I will be able to apply this in not only in my work place but also in my home and maintain safety. I believe that I will be able to spread this knowledge that I have gathered and educate our society in terms of health environment and safety related issues.

In conclusion I would like to mention that while preparing this internship report I have received the finest supervision from my supervisor Ms. Afsana Akhtar, which made it possible for me to be able to complete it and add so many details to my report regarding onsite and offsite information. The experience that I gathered while working with her has added an appreciable value to my educational and professional life because now I am confident enough that in future I will be able to perform better reporting and it will help me further in life. Throughout writing this report I gathered huge knowledge and brushed up my writing and reporting skills which is also an added advantage according to me.

Recommendation

I have few things to recommend to MIR Trading company regarding their business procedure, manpower hire and selection, transparency in their managerial activities, salary and pay structure and last but not the least I would like to recommend some modifications or improvement in the accommodation, food, and transportation system for the employees which is provided by MIR Trading company.

Starting from the last point which I mentioned earlier, MIR provided a travel allowance of 700/=BDT per trip to the technicians and engineers who were not local. Here I would like to say that MIR should have used its own transportation system as it already has the provision of using it. If they used their own transportation system then during the hartal days the employees could feel safer and had a hassle free travel.

MIR rented an apartment especially for this project and tried to facilitate the accommodation of the technicians and supervisors in that apartment. But they did not properly check the facilities provided by the apartment owner. I personally felt that MIR should have tried to provide a better place where technicians and the supervisors had to stay throughout their rotational duty.

Supplied water, food and hygiene should have been better, I had a pretty hard time coping up to that environment. After more than 12 hrs of hard work from 6am to 6pm if you cannot take a hot water bath during the frosty cold winter time you will eventually get sick and catch common cold. Many of my technicians including myself had to face this problem. This should have been taken care by the health environment and safety team of MIR trading. So my recommendation in this case is MIR should take necessary steps to mitigate this issue and use their HES team more effectively.

In this project MIR charged Chevron showing that all the technicians are highly skilled but the reality was not the same. During the time of hiring MIR had to face some community issues and sun of the soil issue so MIR hired technicians from Jakaria Enterprise which is a local contractor of Sylhet. MIR even paid them more than the skilled technicians of MIR trading who have been working for years in generator maintenance section. So in this case there has been a sheer discrimination to the original technicians of MIR who knew the job properly and were much more technically skilled but they were under paid and those hired technicians of Jakaria Enterprise who did not even know the name of the tools and equipments were paid much more roughly Jakaria’s payment was double than MIR’s technicians. In my team there were people supplied by Jakaria Enterprise who used to be car driver who did not even knew how to hold a spanner and unbolting of studs and I had to train them regarding every steps during the work of gasket replacement project. It was a big challenge and problem for me at times. If MIR had taken proper interviews and checked about their mechanical skills then I could have run this project more smoothly. Here my recommendation is MIR should develop a proper recruitment process and hire workers with proven track records and setup a fixed salary structure on the basis of skills. In this project I figured out that MIR did a financial discrimination to the technicians. The technicians who came to work with a stronger reference had a higher range of salary but the skilled technicians were paid less. Also during this project I had to work on two locations simultaneously and supervise 16 technicians at a time in two locations. MIR should have hired two onsite supervisors for every rotational duty. I felt there was a lack of manpower, for a single person supervising 16 technicians in two locations it becomes too much physically tiring and mentally exhausting. This issue should have been taken care by the upper management of MIR Trading Company.

Working in MIR Trading Company is somewhat like working in an environment of uncertainty where employees hardly have an appointment letter yet they are working because they are getting paid at the end of the month. If management had more transparency regarding the upcoming projects or work to be done then the employees would have a clear goal regarding their career. I would highly recommend MIR to work on this issue so that employees’ job satisfaction increases and then they will be much more motivated towards their work and yield a higher productivity from them.

Last but not the least recommendation is that MIR should have signed a contract with Chevron in such a way that the materials and tools required for this project will be supplied by MIR Trading as well. During work I had to wait for Chevron Bangladesh to supply me with the desired tools and materials required and it created a waste of time in some ways. Also if MIR could supply tools and materials then there would have been much more profit in this project from the context of Business. Finally I have to say that MIR Trading Company needs to be more structured and organized, build a professional working environment only then MIR will be able to reach the zenith of success and the vision would be achieved.