Duke University engineers have demonstrated a prototype X-ray scanning machine that reveals not only an object’s shape but also its molecular composition. With its unprecedented resolution and accuracy, the technology has the potential to transform a wide range of fields, including cancer surgery, pathology, drug inspection, and geology.

Many of the concepts underlying the prototype were developed in the pursuit of better bomb detection for aviation security. The researchers adapted the technology for several targeted scientific and medical applications in their new paper, which was published online on May 19 in the journal Scientific Reports.

“Whether you’re looking for a bomb in a bag or a tumor in a body, the physics is pretty much the same,” said Joel Greenberg, associate research professor of electrical and computer engineering and medical physics program faculty. “However, from an engineering standpoint, the constraints on the two are very different. We created this smaller, higher-resolution device to show that our approach could be used for a variety of applications.”

Engineers demonstrated a prototype X-ray scanner that spots cancers and analyzes drugs in minutes. With unprecedented resolution and accuracy, the technology could revolutionize a wide range of fields such as cancer surgery, pathology, drug inspection, and geology.

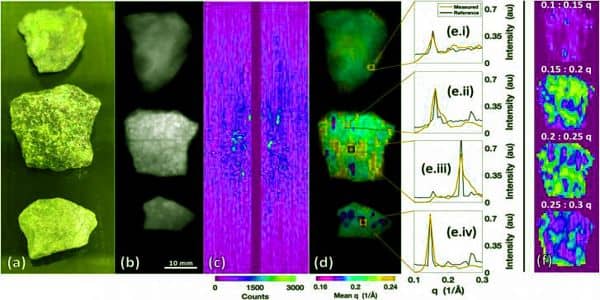

The system is a hybrid X-ray system that combines traditional X-ray transmission radiography and X-ray diffraction tomography. The former entails measuring X-rays that pass directly through an object. The latter involves obtaining deflection angle and wavelength information from X-rays that have scattered (or bounced) off of an object, which provides a sort of “fingerprint” unique to the atomic structure of that material.

One of the barriers to widespread adoption of this technology is that the scattered X-ray signal is typically very weak and complex. As a result, only a few X-rays reach the detector with each image captured, resulting in lengthy delays while the scanner collects enough data for the job at hand.

The Duke team’s method employs a coded aperture, which is a pierced shield that allows X-rays traveling at various angles to pass through its holes. The key is to understand the precise pattern used to block the X-rays, which a computer can then use to process the larger, more complex signal. This allows the researchers to collect enough deflected X-rays to identify the material in a shorter amount of time.

The researchers created a new method for creating high-quality, 3-D coded apertures in the paper, designed a new machine end-to-end with a user interface and a small footprint, and built a prototype using off-the-shelf components commonly used in medical imaging.

“Improving algorithms and implementing advanced manufacturing were critical to achieving the desired imaging performance,” said Stefan Stryker, a Ph.D. student and the paper’s first author.

“Security scanning systems have different goals than oncology labs,” Anuj Kapadia, who was an associate professor of radiology and faculty in Duke medical physics at the time of the research but is now at Oak Ridge National Laboratory, explained. “Security systems must peer through tens of centimeters of random objects in a matter of seconds, whereas our goal was to obtain a high-resolution image of a small, well-defined specimen in a shorter amount of time.”

The prototype scanner’s biggest challenge was making accurate diagnoses of potentially cancerous tissues. The researchers scanned tissue biopsies with colleagues at Duke Health before sending them to resident pathologists for clinical workups. The scanner not only accurately matched the clinical diagnosis, but it also reliably distinguished between tissue subtypes in and around the cancerous tissue.

“Our ultimate goal is to have one of these scanners in every operating room so that surgeons can get an instantaneous diagnosis as soon as the cancer is removed and can immediately check to see if any cancerous cells are present on the edges,” Kapadia explained. “That way, if there’s any doubt that they missed some of the cancer, they can go back and get the rest right away.”

“While pathologists can often evaluate margins while the patient is still in the operating room, specimens removed at surgery for tissues like breast require a 24-hour processing cycle before their margins can be properly assessed,” said Shannon McCall, associate professor of pathology, vice chair for translational research in the department of pathology, and director of the Duke BioRepositories (Duke BRPC). “It would be fantastic if this new instrument allowed us to accurately assess the margins of these types of tissues while the patient was still in the operating room. Women may be able to avoid additional surgical procedures.”

The researchers then demonstrated that the scanner could perform real-time pharmaceutical analysis. This could not only help manufacturers ensure the reliability of their product, but it could also be used by police forensics departments or public health campaigns to ensure that people are not selling or overdosing on tainted drugs.

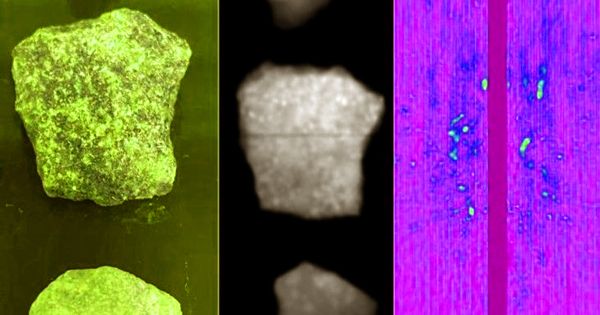

The scanner was also able to quickly analyze rocks loaned to them by an amateur collector, Greenberg’s nine-year-old daughter, Madelyn. Such analyses could be beneficial to archaeologists researching fossils or miners deciding which ore to use in their extraction facilities.

In the future, the research team will use a National Institutes of Health grant to optimize the scanner for tissue samples. Greenberg and Kapadia, along with colleagues Michael Gehm (Duke) and Amit Ashok (University of Arizona), founded Quadridox Inc. to translate the technology into products that could be optimized for larger rocks, faster pharmaceutical scans, or biospecimen analyses.

“We built this scanner to demonstrate all of the different types of things it could do,” Greenberg explained. “However, a commercial machine for each application may have its own set of engineering variations, such as how we make measurements, the sensors we use, or the architecture.”

“If you were designing a projector, you would need to know whether it would be used in a dark theater or in broad daylight. The requirements would be completely different “Kapadia added. “Similarly, our goal here is to identify a wide range of applications where these types of scans could be useful, and then engineer a variety of scanners to meet their specific requirements.”