A major issue, counterfeiting costs huge sums of money, raises safety issues, and endangers people’s health in a variety of sectors, from electronics to medicine.

Counterfeiters and anti-counterfeiters are now locked in a technological arms race. Even while anti-counterfeiting technologies like holograms, thermochromic ink, and radio frequency identification tags are getting more and more sophisticated, it is getting harder and harder to differentiate fake products from real ones since counterfeiters are utilizing more and more sophisticated technology.

Recently, a team of researchers led by Dr. Zhiqin Chu of the Department of Electrical and Electronic Engineering of the University of Hong Kong (HKU), together with Professor Lei Shao of the School of Electronics and Information Technology of Sun Yat-sen University, and Professor Qi Wang from Dongguan Institute of Opto-Electronics of Peking University developed a pioneering technological solution that counterfeiters have no response to.

PUFs, or Physically Unclonable Functions, are special diamond-based anti-counterfeiting labels that Dr. Chu’s team developed.

Diamond anti-counterfeiting will be favoured in various high-end products such as jewellery, luxury goods, electronic products, and automobiles.

Dr. Zhiqin Chu

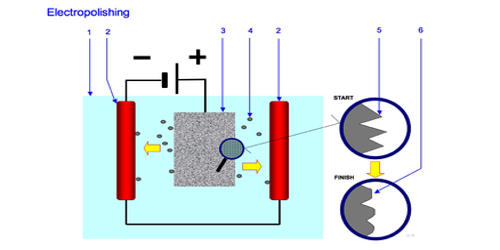

The scientists used a process called Chemical Vapour Deposition (CVD) to create these labels by depositing diamond microparticles, which are extremely small synthetic diamonds, on a silicon plate.

When the diamond microparticles disperse across the silicon substrate, their various sizes and shapes combine to create a singular pattern. Such a pattern scatters light in a distinctive manner since it cannot be duplicated. Put simply, it forms a unique “fingerprint” than can be scanned using a phone.

The second level of uniqueness, and hence security, comes from the fact that these diamond microparticles have defects known as silicon-vacancy (SiV) centers.

Diamond microparticles with SiVs have a special optical feature that makes it easy to identify them when a green light is shone on them; they generate near-infrared photoluminescence.

Then, using a cheap smartphone scanner and/or a confocal fluorescence microscope, one can combine and digitize these distinctive optical signatures to create incredibly sophisticated and secure codes.

Importantly, these labels made of diamond are ideal for use on industrial goods because they are incredibly durable; in tests, they withstood heat, chemical action, and physical damage.

And, they are cheap it costs just one US dollar to make 10,000 such labels of 200 µm × 200 µm dimensions. Moreover, because they are made from diamonds, these anti-copying labels would enhance the value of the product.

The labels are ready to be used commercially, says Dr. Chu, adding that the team’s next step is “to focus on the practical application.”

“Diamond anti-counterfeiting will be favoured in various high-end products such as jewellery, luxury goods, electronic products, and automobiles,” he said.