Employee safety and security

in SIM Group

SIM Group is an umbrella enterprise having several textile-oriented companies under a single ownership. This report illustrates current condition and problems concerning safety and security of its workers. The objective of this report is to access the employee safety and security issues from a perspective of human resources management, and provide some recommendations based on the accessed findings.

To fulfill this objective, a survey using 13 semi-structured questionnaire is conducted where quota sampling method is utilized having a sample size of 30 from all three major sections of the company. In addition, direct observation of the intern is also used to access further facts that are not captured by survey. Findings from both sources are compiled to provide the recommendations.

The findings reveal that, although SIM Group does have several nice features regarding employee safety and security, it is not free from serious drawbacks. Among them, the most severe ones are that most of the personal protective equipments are not replaced regularly; some of those, such as mask, are uncomfortable; a big portion of the workers do not wear these protective equipments; and the ribbon band of ID card and unsmooth dyeing floor may cause accident. In addition, no proper footwear is given to the workers and first aid box is also limited. Moreover, among others problems, there are severe problems in female dormitory that are need to be fixed.

To fix these issues, eleven recommendations are provided, which may improve the overall condition of safety and security from a perspective of human resources management.

Objective

The objective of this study, as the title says, is to access the employee safety and security issues of the SIM Group, from a perspective of human resources management, and provide some recommendations based on the accessed findings.

The report is limited exclusively to the SIM Group, and the study only covers safety and security related issues, nothing more.

ORGANIZATION AND DEPARTMENT OVERVIEW

An overview of the SIM Group will be given in the current section. First, I shall provide a general overview of the company, followed by its history and current management. A list of all the companies under this group will also be given, along with description. Next, brief description of the products will be provided. In the final section, I shall mention some of the biggest corporate customers of this company.

Most of the information of this section is collected from their official website (www.simgroup-bd.com) and from the 2014 annual report.

About the company

SIM Group is an umbrella enterprise having several companies under a single ownership. All the companies under this group are separate legal entity, each registered separately with the Company Act 1994. All these companies are engaged in producing textile and apparel related products, ranging from spinning to dyeing to weaving. These companies do not sell products directly to end consumers. Instead, their main customers are corporate buyers. Although it is written on their website (www.simgroup-bd.com) that they are 100% export-oriented firm, in fact they have local customers as well.

Nevertheless, most of their customers are indeed from foreign country.

In their own language, “SIM GROUP has grown from a staring fabric manufacturer to an exporter of entire range of fashion.”

History

There are several companies within the group. Among them, Authentic Color was established in 1999. After one year, in 2000, SIM Fabrics was established. Mozaffar Hossain Spinning Mills was established in 2006, and the dyeing section in 2012. One of the companies, Mozaffar Hossain Spinning Mills, issued IPO in 2013 with a total offer price of Tk 275,000,000, and became a public limited company since then.

Products and Services

SIM Group outputs both products and service related to textile and apparel. It provides following services to its clients:

— Spinning service,

— Weaving service,

— Dyeing & Finishing of Woven Fabrics, and

— Designing of new fabrics.

In addition, SIM Group has its own line of products. Such as, Herringbone, Matt, Dobby, and Bedford cord. This company used to supply Stretch twill, Stretch canvas, Stretch Slub, Stretch dobby, Stretch sateen, and Poplin under the GSP facility when Bangladesh had GSP support from USA.

Customers

Main customers of tth SIM Group as a whole are Carrefour, Spring field, Kik, Takko, Aeropostle, C&A, Primark, Lands end, Tcp, Terreanova, Tesco, George, Lidl, Kiabi, H&M, Zara, Bershka, Tema, and Herma.

Besides, there other customers exclusively for Authentic color, such as, Newtex Group, Youth group, SP Group, Thermax Group, Far East Knitting, P.M Knitting, Mimtex Group, Urmee Knittex, Anwar Group, Purbani Textile.

Overview of the study

As the title says, this study accesses and evaluates the safety and security issues of SIM Group regarding human resources. To fulfill this objective, I relied on two approaches – namely, survey and observation.

The Survey

In my survey based part of this study, I prepared a questionnaire containing 13 questions regarding various safety and security related issues. This is a structured questionnaire, having a MCQ like style. Although respondents are selected randomly, it is ensured that all three sections (dyeing, spinning, and weaving) are included. Therefore, it is not pure random sample. More appropriately, my sampling method falls in Quota Sampling category, because it is ensured that all workers from all three major sections are included.

The fieldwork: The survey was conducted on 12th and 14th March, 2015, with the permission of my superior. A sheet containing 13 questions on a single page is served as questionnaire. For each 30 respondents, 30 different sheets are used. A screenshot of the questionnaire is given next:

As the picture shows, there are rooms for collecting respondent’s personal opinion or my own opinion regarding each question. Moreover, date, time, location, gender stamp, and a comment box is placed on the questionnaire, for my own convenience.

The result of the survey is compiled using Microsoft Excel to get the aggregated picture.

Direct Observation

Direct observation, which consists of recording the behavioral patterns of people, objects, and occurrences as they witnessed, is used in the second part of my study. I observed the issues that I think important regarding safety and security of the workers. Like the survey, here I also put almost equal weight in all three sections (dyeing, spinning, and weaving).

Note that, all my observations fall in Direct Observation category, as I did not made any attempt to create an artificial environment to observe my objects. Therefore, there is no use of Scientifically Contrived Observation in my study.

Final result

Based on the result of survey and observation, I tried to make a combined true picture of the safety and security of this company. And of course, some recommendations are also provided that I think will become useful for the authority.

Data analysis

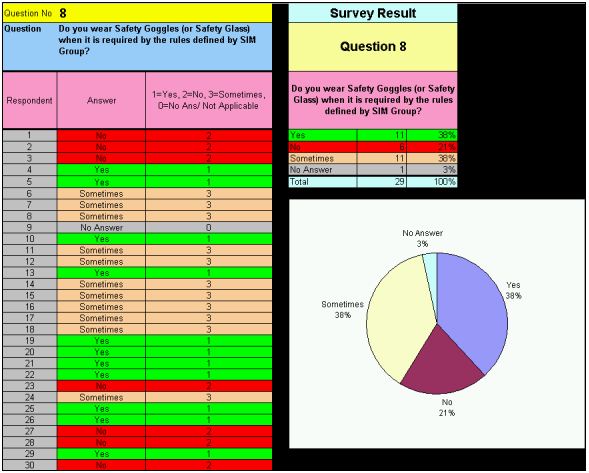

A structured worksheet, created using Microsoft Excel, is used to convert the raw survey data into digital data. This worksheet is created in such a way that, I have to enter only four buttons (1 for “Yes”, 2 for “No”, 3 for “Sometimes”, and 0 for “No Answer”) to enter the data. Because of this procedure, the error in data entry is entirely minimized. Besides, it has other capabilities, which are discussed next:

As the picture shows, this worksheet has several characteristics, which made data entry extremely easy and error free:

— I have to enter only one of the four buttons (1 for “Yes”, 2 for “No”, 3 for

“Sometimes”, and 0 for “No Answer”) to enter the data of a question of a particular respondent.

— Automatic color coding: Yes, No, Sometimes, and No Answer are displayed in green, red, orange, and gray color, respectively. Thus, it is easy to indentify and verify each record while entering data.

— It automatically shows the percentage value of each possible answers. Such as, 60% respondents selected “Yes”, and 40% selected “No”.

— And finally, it automatically makes the pie chart showing aggregated result of a particular question of the survey.

Separate form, identical to the picture above, is used for each 13 questions. Finally, the pie charts are observed to access the conditions of various issues of safety and security.

FINDINGS BASED ON SURVEY

In the previous section, I already discussed about the methodology that is used in this study. In the current section, I shall present the result of my survey. Note that, there are 30 respondents in this survey, and for each respondent, there are 13 questions. Therefore, total number of answers is 30 x 13 =390.

To analyze this large amount of data, I relied on Microsoft Excel. In fact, a special worksheet is used that served as both data entry form and pie chart creator. Details about this are already mentioned previously.

Given bellow, a list of all the questions that are used in this survey:

- Do you wear Mask when it is required by the rules defined by SIM Group?

- Do you wear Ear Plugs when it is required by the rules defined by SIM Group?

- Do you stand on a Rubber Mat when working with electricity or when it is required by the rules defined by SIM Group?

- Do you wear Hand Gloves when working with chemicals or when it is required by the rules defined by SIM Group?

- Do you wear Gum Boot (or Wellington boot) when working with chemicals or when it is required by the rules defined by SIM Group?

- Do you wear Scarf when working with/near a moving machine or when it is required by the rules defined by SIM Group? (This question is only for women)

- Do you wear Apron when it is required by the rules defined by SIM Group?

- Do you wear Safety Goggles (or Safety Glass) when it is required by the rules defined by SIM Group?

- Do you wear Ear Muffler when working near loud sound or when it is required by the rules defined by SIM Group?

- Do you wear Organic Vapor Mask when it is required by the rules defined by SIM Group?

- Do you wear ID Card at your workplace?

- Do you know what to do if there is a fire on your workplace?

- What is the total number of trainings (safety and security related) you received from SIM Group?

Except last two questions (Question no. 12 and 13), each have three options to answer from – Yes, No, and Sometimes. However, there are room for me and for the respondent to express comment / cause if the answer is No or Sometimes.

The bold words of each question indicate what the question is all about – the topic of the question. As you see, each question handles a particular topic. I believe that these 13 topics cover a wide range of issues regarding safety and security of the company.

Nevertheless, I should admit that there are other issues in the safety and security category that are not covered here. The reason is that, my superior restricted me not to exceed total number of questions to one dozen.

I believe that, workers need to ensure that their name / ID etc will not be recorded, because workers usually do not agree to provide data in a fear that, it may result loosing their job. Hence, privacy of respondents is crucial. That’s why, as I invented a privacy policy and stated at the bottom of the questionnaire, is that: “The name, ID, or any personal information of the participant is not recorded while conducting this survey.”

Given from the next page, the result of the survey.

Question 1: Mask related

Do you wear Mask when it is required by the rules defined by SIM Group?

Mask is a vital PPE (personal protective equipment) that prevents dusts and chemicals to be entered into the mouth and nose. Workers must wear it at the factory.

Most of the workers wear mask at their work, as indicated by 70% figure. Only 10% do not wear it, and remaining 20% wear it sometimes. Those who do not wear it mentioned several reasons. For instances, some of them do not have the mask – that is, they never got it from the company. There are others who simply do not like to wear it.

Some of the workers (20%) wear mask sometimes. The reason is that, they often forget to wear it or bring it from home. But the most prominent reason is that, they feel suffocated when wearing it, because it is too tight.

Nevertheless, they wear it when a compliance checking is going on.

Question 2: Ear Plugs related

Do you wear Ear Plugs when it is required by the rules defined by SIM Group?

Ear plug is a PPE that prevents loud sound entering directly into the ear. The good news is that, as many as 74% of the workers do wear ear plug when they work, which protects their ears from loud sound coming from machineries.

Only one worker (7%) admit that he never wear ear plug. Because, he does not have it yet.

Roughly one-fourth, or more precisely 23% of the workers wear ear plugs sometimes.

Some of them in this group become used to loud sound, so they think that they don’t need it. Personally, I suspect that their ears have already become damaged; hence they do not annoyed by loud sound anymore.

Nevertheless, the most common reason of not wearing ear plugs is that, the equipment is damaged due to continuous use, and the authority never gave a new replacement.

Question 3: Rubber mat related

Do you stand on a Rubber Mat when working with electricity or when it is required by the rules defined by SIM Group?

When a worker is working near or with the electricity, s/he is required to stand on a rubber mat. As written on the workers’ manual of SIM Group, the worker have to stand on a rubber mat when working with or close to DB / SDB board. This requirement prevents them from accidental electric shock.

Roughly half (47%) of them follow this rule, half (43%) do not. They pointed out several reasons. Most common reason is that, they view this rubber mat as an extra hassle. Some of them, especially who have experience with electricity, think that rubber mat is not required because they are (they think) too experienced.

Nevertheless, the most common cause is that, there is not sufficient number of rubber mat to use.

Question 4: Hand gloves related

Do you wear Hand Gloves when working with chemicals or when it is required by the rules defined by SIM Group?

Wearing hand gloves is required when working with chemicals.

The result shows that, most of them (70%) wear hand gloves or similar items.

However, 23% do not wear hand gloves. The reason, as they mentioned, is that they do not have it – never got from the company.

Few of them did get it, but they lost it somewhere. Two workers (7%) said that they sometimes wear hand gloves – only when the chemical is too uncomfortable to touch.

Question 5: Footwear related

Do you wear Gum Boot (or Wellington boot) when working with chemicals or when it is required by the rules defined by SIM Group?

According to the workers’ manual of SIM Group, the operators of chemical and dyeing section must wear gum boot to protect their feet from chemical reactions. Almost half (47%) of the workers wear gum boot. The graph also shows that, 10% of the workers do not wear this footwear.

Remaining half of the workers (43%) do not wear gum boot. The reasons are, but not limited to, the fact that the company never supplied this special footwear among for the workers. My personal observation is that, supplying such expensive footwear may cause significant cash outflow from the company.

Question 6: Scarf related

Do you wear Scarf when working with/near a moving machine or when it is required by the rules defined by SIM Group?

Unlike other questions, this one was targeted only towards women workers. The company requires that, female workers have to wear scarf when they work near moving machineries. This will prevent their hair being accidentally stuck with the moving parts of the machine.

70% of the workers do not wear scarf, and almost all of them are male workers. A few female workers do not wear this because they do not have it, or they once have it, but get damaged and company did not provide a replacement.

30% of the workers wear scarf, and all of them are female.

Question 7: Apron related

Do you wear Apron when it is required by the rules defined by SIM Group?

According to the workers’ manual of SIM Group, an apron helps the workers to become attentive, and also distinguish the departments they belong to.

Slightly more than half (53%) of the workers do wear apron. However, 20% workers never wear apron, and main reason is that, they do not have it.

About one-third (27%) workers wear apron sometimes, not always. In this group, they wear an apron only when they expect a possible compliance checking. This kind of checking happens usually when a buyer comes.

Most common reason of not wearing apron is that, they never got it from the company.

Question 8: Safety goggles related

Do you wear Safety Goggles (or Safety Glass) when it is required by the rules defined by SIM Group?

Safety goggles protects the eyes from hazardous environment. For example, it may prevent toxic chemicals to be entered accidentally in the eyes of the workers. The answer to this question is interesting. 37% of the workers always wear safety goggles, and exactly equal numbers of workers wear it sometimes.

But, as high as 23% of them do not wear it. The reason is either they do not have it or they find it uncomfortable. Another reason is that, they once have it, but now damaged and never get a replacement from the company.

FINDINGS BASED ON OBSERVATIONS

In the pervious section, I mentioned the findings that came out from the result of my survey. In the current section, I shall describe what I found from my own observation, apart from the survey.

Note that, this observation does not fall under Scientifically Contrived Observation category, because I did not influence the environment. All my observations are actually direct observations at the working sties without any attempt to create an artificial environment.

Security/Safety Problems and Hazards

First aid box: According to the Labor Act, there should be at least one first aid box at each working unit. But in fact, SIM Group does not have even one first aid box in most of the workplace. This condition is directly contradictory to the current Labor Act of Bangladesh.

Serious problem on dyeing floor: On 21st March, a worker named Jubayer Alam (ID: 0913) had a serious accident, which broke his nose. He fell while he was dragging a dyeing instrument on floor. The underlying cause, as I observed, is that the dyeing floor is not smooth. This kind of accident can easily be avoided or even eliminated if the authority make the floor smooth, hence a smooth floor will cause far less friction and workers will no longer have to loose their balance while dragging heavy machineries.

Hazardous pathway in female dormitory: If a female worker has to get out from the dormitory, she has to follow these steps:

— First, she has to go to roof of the dormitory, at 3rd floor.

— Then, she has to jump to the next building’s roof.

— From there, she has to come down to the ground floor through the stairway of that building.

— Finally, when she reaches the ground floor, she can go outside from the dormitory.

Similarly, when she needs to enter the dormitory again, she has to follow all these steps again, but in reverse order.

Interestingly, a door does exist next to the dormitory, but always locked. If this door remains open, female workers do not have to go through this hazardous steps when entering in to or out from the dormitory. But the authority never cares that.

Location of toilet in female dormitory: The only toilet is located at the 2nd floor, while most of the female workers stay in the ground floor. They do not usually go to toilet at night because of its inconvenient location. Besides, many of them think that if they go out on 2nd floor in the middle of dark night, some bad spirit may possess them. Nevertheless, this problem can easily be solved by constructing another toilet on the ground floor.

Damp air in weaving section: In the weaving section, there is no exhaust fan. Lack of scope of getting air out makes the whole section damp like environment.

Water related problems: Is the water related to safety and security?

Yes, indirectly. Water is related to health, and health in turn related to security and safety. But unfortunately, there is less than sufficient water supply in the staff quarter, and same is true for workers’ quarter. Especially at staff quarter, extreme water shortage regularly occurs every working day during 7 to 9 am, and again during launch hour. In addition, the water tank has not being cleaned for more than one year.

Problems in toilet: First to say, male and female workers do share same toilet, because they have no other choice. There is no separate toilet designated for separate gender.

Moreover, there is no light in the toilet, and door-lock facility has been broken for long time. Same is true for commode – it is broken too. There is no toilet paper or any towel in the toilet, and also no soap or hand wash. Besides, it is not cleaned regularly. These are related to workers’ health, hence indirectly related to safety and security.

No Day Care: A large number of female employee work at the weaving and spinning section (unit – C). Although most of them have children, SIM Group does not provide any facility to look after those children while their mothers are working. Lacking of a day care service forces these mothers to worry about their children and some of them are interested to quit the job just for this reason. However, this problem is not severe in dyeing section as number of female workers is few in that section.

Some good features

So far, I discussed about bad issues that hamper the overall safety and security of the company. However, my observation also captured several good sides. Such as:

Internal Audit: The company has a really good internal audit policy that works.

Salary: Unlike many factory-oriented companies in Bangladesh, SIM Group provides good salary to both its workers and staffs, and delay or due in providing salary is a very uncommon event here.

On-site Medical Support: All employees and workers do get good medical support. I saw that a female doctor always running from here to there to provide emergency medical support during all the working hours.

Comply with Labor Act of Bangladesh: Internal rules and regulations of SIM Group are compatible to the current Labor Act of Bangladesh. It may not be irrelevant to mention that, one of my duties was to ensure that, new rules of the company fully comply with the Labor Act 2006.

No child labor: The Company is determined not to employ anyone under 18, to comply with the labor act. For instance, when a new worker is about to join, medical staffs examine his/her teeth to ensure that, s/he has 32 sets of teeth. This checkup ensures that, the age of the worker is above 18.

CCTV Cameras and security: There is sufficient number of CCTV cameras at the worksite, which reduces the incident of theft. I would like to mention one incident, in which I lost my mobile phone – of course someone at the job site stole it. Then the manager declared that all the video recordings will be replayed to find the thief, and just after half an hour of this declaration, I surprisingly found that someone kept away my phone to its original place – my work desk.

Overtime policy: SIM Group does not force any worker for overtime. However, if anyone willingly does overtime work, s/he will get compensation. Really nice compared to other factory-oriented firms in Bangladesh. This issue is indirectly related to long term safety because this kind of policy determines whether or not workers will engage in violent movement.

Safety and medical allowance: Finally, it should be mentioned that, SIM Group provides basic safety and medical facilities, and house rent allowance up to 35% of the basic salary.

RECOMMENDATIONS

So far, I have presented findings both from the survey result and from my own observations. In the current section, I shall try to provide some recommendations for the Group based on these findings.

Note that, these recommendations are not for the employees or workers – these are for the authorities of SIM Group. Moreover, these recommendations are entirely for improving the safety and security issues of the company. Recommending for more profit or market success are out of the scope of this study and they are also not my subject to cover.

Recommendations based on survey findings

(1) Mask should be more comfortable: Mask is an important PPE (personal protective equipment). But unfortunately, almost 30% of the workers never wear mask or only sometimes wear it. The reason is that, these are too tight, which make them feeling suffocated. Once I tried a mask, and I also felt suffocated too. My recommendation is that, the authority of SIM Group should supply new masks that are more comfortable.

This action will incur little cost to the company, but in turn ensure long term safety especially for the folding and weaving machine operators.

(2) PPEs should be replaced every two months: Most of the PPEs (personal protective equipments), like masks and ear plugs, should be replaced by new ones every two or three months. These protective equipments usually get damaged with regular use, and it is the duty of the authority to replace them in time. From my observation, it seems that, the company thinks that they have done enough by providing these equipments only once (when a worker joins). This tendency must be changed.

(3) ID Cards: Ribbon Vs. Clip: SIM Group supplies ID cards with ribbon band (about one feet long) to wear on the neck. However, my survey reveals that, many workers think that this ribbon may cause an accident by getting stuck with moving parts of machineries.

To prevent this kind of accident and at the same time to ensure that workers do not abandon their ID cards, the ribbon band can be replaced by clip. Then workers can pin their ID card simply using the clip with their cloths, and this approach is far more safety.

(4) The authority should provide proper footwear: An alarming finding from the survey is that, as many as 43% workers do not wear gum boot when they are required to. Another 10% only wear it sometimes. Combinedly, 53% do not wear it regularly, even though they are working in chemical and dyeing section. The reason is that, they never got it from the company. Although this is much more expensive than other PPEs, the authority should supply sufficient gum boots among the workers, even if that results significant amount of cash outflow.

(5) How to ensure that workers wear PPEs: Personal protective equipments (PPE) are vital in preventing minor injuries and major accidents. Unfortunately, most uneducated workers do not understand the necessity of wearing these PPEs – they usually believe that nothing will happen to them because each of them thinks himself or herself experienced (whether they truly are or not). One solution to this problem is that, the authority should be very strict in this matter so that, workers are forced to wear these PPEs. My

Suggestion: a very small portion of salary of a day can be deducted if a worker fails to wear these at a particular day. The deducted portion of the salary should be placed in an interest-bearing deposit, which will in turn be used in future for the betterment of the workers. In addition, PPE related trainings and awareness programs should also be increased.

Recommendations based on observations

(1) Smooth the dyeing floor: First and foremost, the dyeing floor must be smooth. One worker had severe accident in front of me (I already mentioned this in this report), and this kind of accident can be prevented if the floor is made smooth. Yes, the solution is such simple. Therefore, I advised the authority to take care this matter immediately.

(2) Water related issues should be fixed: As I already mentioned, there are severe scarcity of water in both staff quarter and workers’ quarter. This problem can easily be solved by installing two more water tanks. In addition, associated machineries, such as water-motor or pump many needs to be installed, too. The solution is such simple, but it will ensure continuous supply of water in those two quarters.

(3) Increase the number of first aid box: The number of first aid box that SIM Group have does not comply even with the Labor Act of Bangladesh, which is in fact quite relaxed compared to the same of other countries. My recommendation is that, every work unit place should have at least two first aid boxes. Someone from the workers (who work in that particular unit) can be assigned to look after these boxes so that in time of necessity s/he can quickly bring it.

(4) Issues need to be fixed in female dormitory: First, the authority have to construct a toilet on the ground floor of female dormitory. Yes, there is another one at 2nd floor, but that is almost useless in the night because female workers are afraid of ghost (I already explained this previously in this report). And second, there is a door on the ground floor of female dormitory which is used to be the gateway – but always remains closed. This forced female workers to jump to the roof of the next building for getting in and out. This gate should be opened, immediately. If that caused problem, then the authority have to tackle that problem in alternative and matured ways, not by shutting down that door.

(5) Fix those toilets: It may sound funny on an internship report like this, but it is the truth. Clean toilets are related to health, hence indirectly related to safety and security.

Here is a list of what to be done: First, ensure that doors can be closed from inside. Second, keep sufficient amount of toilet papers etc and washing materials in toilets.

Third, fix those broken commodes. And finally, but most importantly, assign separate toilets for male and female workers.

(6) Build a day care: For the large number of female workers at spinning and weaving section, most of whom have children, I recommend building a day care within or near the C unit with capacity of one hundred or more children. This action will definitely reduce the turnover rate of married female workers.

CONCLUSION

The objective of this study (see page 4) was to “access the employee safety and security issues of the SIM Group, from a perspective of human resources management, and provide some recommendations based on the accessed findings.” From this viewpoint, I can consider this study as a success, as I presented several important issues of safety and security of the company, and also provided recommendations that I believe will improve the condition of the company in terms of safety and security.

Now, in this concluding chapter, I would like to share my very own personal experience at this company.

I was selected as the HR and Admin Executive from short-listed candidates, and when I first joined the firm, on 26th January, I was excited. I had no prior idea what kind of firm it is. Gradually, it was revealed that the corporate culture of this company is far from ideal.

First, the most prominent negative aspect in the corporate culture of this firm is that, high ranking officers such as managers and similar ranking officers use slung language to get the work done. No matter whether the work is flowing smoothly or not, whenever a higher entity needs to call a subordinate, he will use a slung language to call him.

Second, the environment at corporate level is not suitable for female executives and officers. Yes, there are hundreds of female workers working at factory, but almost none at corporate level. One reason is the slung language itself that I already mentioned. Another reason is that, as there are almost no female officers/executives here from the establishment of the company till today, the co-workers are not ready yet to see and accept a female colleague. For example, in case of me, they could not accept me normally. Sometimes I get the feelings that they are afraid of diversity.

Nevertheless, the textile and garments industry of Bangladesh has reached such a high rank in world market due to the contributions of companies like SIM Group and others, and as a citizen of Bangladesh, we all should be grateful to these productive firms. If they can improve their corporate culture and accept diversity, then I believe that the firm can do even better.