An electromagnetic clutch is a form of clutch that uses electromagnetic force to engage and disengage the machine’s driving and driven components. This type of clutch is widely utilized in a variety of applications, including automotive, industrial, and HVAC systems.

Electromagnetic clutches use electricity but transmit torque physically. This is why they were previously known as electromechanical clutches. Over time, EM became recognized as electromagnetic rather than electromechanical, referring more to its actuation approach than physical operation. Since clutches first became popular over 60 years ago, the number of applications and clutch designs has grown considerably, but the essential operation remains the same.

Single-face clutches account for about 90% of all electromagnetic clutch sales.

Electromagnetic clutches are ideal for remote operation because they do not require mechanical links to govern engagement, resulting in quick, smooth operation. However, when the clutch is engaged, the activation energy dissipates as heat in the electromagnetic actuator, increasing the danger of overheating. As a result, the maximum operating temperature of the clutch is restricted by the electromagnet’s insulation temperature rating. This is a significant constraint. Another downside is the increased initial cost.

Working Principle

- Electromagnetic Force: The clutch operates using an electromagnetic coil that creates a magnetic field when an electric current passes through it.

- Engagement: When the coil is energized, the magnetic field pulls the armature (a moveable plate) towards the rotor (connected to the driving part), causing friction that engages the clutch and transmits torque from the driving part to the driven part.

- Disengagement: When the current is turned off, the magnetic field collapses, and a return spring or other mechanism pulls the armature away from the rotor, disengaging the clutch and stopping the torque transmission.

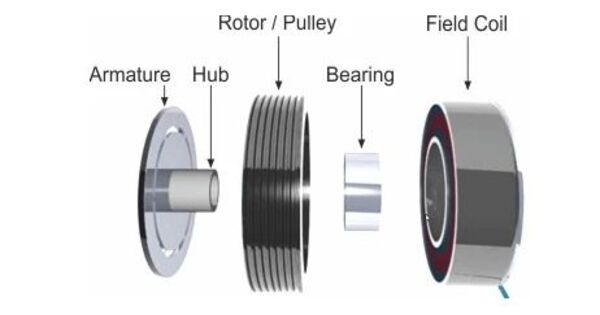

Components

- Electromagnetic Coil: Generates the magnetic field needed for engagement.

- Rotor: Attached to the driving part (e.g., engine or motor).

- Armature: Moveable plate that engages with the rotor when the magnetic field is activated.

- Friction Material: Surfaces on the rotor and armature that create the friction necessary for torque transmission.

- Return Spring: Ensures the armature disengages when the electromagnetic coil is de-energized.

Advantages

- Fast Response Time: Electromagnetic clutches can engage and disengage very quickly, making them suitable for applications requiring rapid cycling.

- Remote Control: Can be easily controlled electrically, allowing for automation and remote operation.

- Less Wear and Tear: Because there is no physical contact when disengaged, wear and tear are minimized compared to mechanical clutches.

- Smooth Operation: Provides smooth engagement and disengagement, reducing shock loads and wear on the machinery.

Applications

- Automotive Systems: Used in air conditioning compressors, cooling fans, and power steering pumps.

- Industrial Machinery: Common in printing presses, conveyor systems, and packaging machines.

- HVAC Systems: Controls the operation of compressors and other components.

- Robotics and Automation: Used in various robotic applications for precise control of movements.

Types of Electromagnetic Clutches

- Single-Plate Clutch: The simplest and most common type, using a single friction plate.

- Multi-Plate Clutch: Uses multiple friction plates for higher torque transmission.

- Magnetic Particle Clutch: Uses magnetic particles between the driving and driven members, offering precise control of torque.

- Hysteresis Clutch: Utilizes magnetic hysteresis properties to transmit torque without physical contact, providing smooth and precise control.