Electromagnetic brakes (EM brakes) are used to slow or stop automobiles by applying electromagnetic force to mechanical resistance (friction). These are braking systems that employ electromagnetism to slow or halt motion. They were initially known as electro-mechanical brakes, but the name was modified over time to “electromagnetic brakes” to reflect their actuation technology, which is typically unrelated to modern electro-mechanical braking systems. They work by converting kinetic energy to thermal energy via electromagnetic induction.

Since becoming popular in the mid-twentieth century, particularly in trains and trams, the number of applications and brake designs has grown substantially, but the basic operation remains unchanged. Both electromagnetic and eddy current brakes employ electromagnetic force, however electromagnetic brakes rely on friction whereas eddy current brakes use magnetic force directly.

Here’s how they typically work:

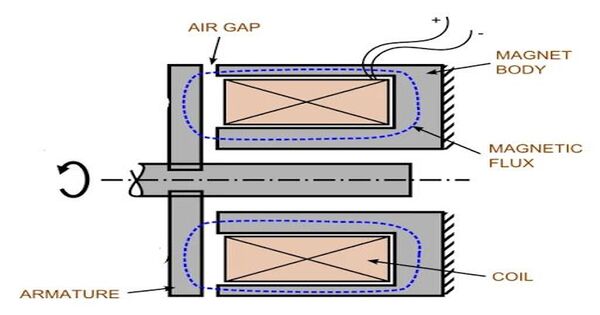

- Electromagnets: These brakes consist of a coil of wire wound around a magnetic core, creating an electromagnet. When an electric current flows through the coil, it generates a magnetic field.

- Rotor or Armature: The object to be braked, typically a rotor or armature, is placed within the magnetic field generated by the electromagnet.

- Eddy Currents: As the rotor or armature rotates within the magnetic field, eddy currents are induced in it. Eddy currents are circular currents that flow within conductive materials when exposed to changing magnetic fields.

- Resistance and Braking: These eddy currents create their own magnetic fields, which oppose the original magnetic field produced by the electromagnet. This opposition results in resistance to the motion of the rotor or armature, effectively slowing it down. This resistance converts kinetic energy into heat energy, dissipating it into the surroundings.

- Control: The amount of braking force can be adjusted by regulating the strength of the electromagnet’s magnetic field, which is commonly done by changing the amount of current running through the coil.

Electromagnetic brakes are commonly employed in applications requiring precise control over braking, such as industrial machinery, elevators, trains, and some automobile applications. They have benefits such as quick response times, great dependability, and maintenance-free operation, making them useful for a variety of situations. Furthermore, because they do not rely on friction to create braking power, they can offer smoother and more consistent braking than typical friction brakes.