In electronics engineering, ‘Electric Fuse’ is a safety device that protects us from fire. It’s essential component is a metal wire or strip that melts when too much current flows through it, thereby stopping or interrupting the current. It is a sacrificial device; once a fuse has operated it is an open circuit, it must be replaced or rewired, depending on type. The property of fuse wire is that it has very low melting point. It is made up of an alloy consisting of lead and tin.

A fuse commonly consists of a current-conducting strip or wire of easily fusible metal that melts, and thus interrupts the circuit of which it is a part, whenever that circuit is made to carry a current larger than that for which it is intended. The screw-plug fuse was once commonly used in domestic electrical systems. It contains a short bit of wire (the fusible element) enclosed in a fireproof container that has a screw-threaded base; the wire is connected to metal terminals at both the screw base and at the side, and the whole is covered with a transparent glass or mica window for seeing whether the fuse has melted. The cartridge fuse, a type of fuse widely used in industry where high currents are involved, has a fusible element connected between metal terminals at either end of a cylindrical insulating tube.

Breguet recommended the use of reduced-section conductors to protect telegraph stations from lightning strikes; by melting, the smaller wires would protect apparatus and wiring inside the building. A variety of wire or foil fusible elements were in use to protect telegraph cables and lighting installations as early as 1864. A fuse was patented by Thomas Edison in 1890 as part of his electric distribution system.

The Unicode character for the fuse’s schematic symbol, found in the Miscellaneous Technical block, is U+23DB.

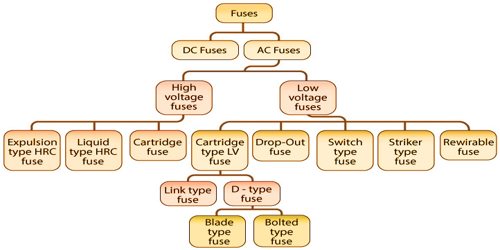

Types of Fuses –

Different types of Electric fuses are available in the market and they are classified on the basis of different aspects. But mainly, fuses can be divided into two categories based on the input supply as follows:

AC fuses

DC fuses

Given below is a flowchart of further classification of fuse:

Automotive fuses are also used to protect the wiring and electrical equipment for vehicles. There are several different types of automotive fuses and their usage is dependent upon the specific application, voltage, and current demands of the electrical circuit. Automotive fuses can be classified into four distinct categories:

- Blade fuses

- Glass tube or Bosch type

- Fusible links

- Fuse limiters

Most automotive fuses rated at 32 volts are used on circuits rated 24 volts DC and below. Some vehicles use a dual 12/42 V DC electrical system that will require a fuse rated at 58 V DC.

Dimensions and Functions of Fuses –

Fuses can be built with different sized enclosures to prevent interchange of different ratings of fuse. For example, bottle style fuses distinguish between ratings with different cap diameters. Automotive glass fuses were made in different lengths, to prevent high-rated fuses being installed in a circuit intended for a lower rating.

Special features — Glass cartridge and plug fuses allow direct inspection of the fusible element. Other fuses have other indication methods including:

- Indicating pin or striker pin – extends out of the fuse cap when the element is blown.

- Indicating disc – a coloured disc (flush mounted in the end cap of the fuse) falls out when the element is blown.

- Element window – a small window built into the fuse body to provide visual indication of a blown element.

- External trip indicator – similar functions to striker pin, but can be externally attached (using clips) to a compatible fuse.

Some fuses allow a special purpose micro switch or relay unit to be fixed to the fuse body. When the fuse element blows, the indicating pin extends to activate the micro switch or relay, which, in turn, triggers an event. Some fuses for medium-voltage applications use two or three separate barrels and two or three fuse elements in parallel.

In the field of electrical engineering, a fuse is a device that provides over-current protection to the functional electrical circuit. Here, we have listed a few major functions of the fuse.

- Acts as a barrier between the electric circuit and the human body

- Prevents device failure due to faulty circuit operation

- Fuse prevents short-circuits

- Prevents overload and blackouts

- Prevents damage that is caused due to mismatched loads

The markings on the fuse carry information such as the Ampere rating, voltage rating and interruption rating.

Uses of Electric Fuses –

A fuse is an automatic means of removing power from a faulty system; often abbreviated to ADS (Automatic Disconnection of Supply). Circuit breakers can be used as an alternative to fuses, but have significantly different characteristics. The primary use of an electric fuse is to protect electrical equipment from excessive current and to prevent short circuits or mismatched loads. Electrical fuses play the role of miniature circuit breakers. Apart from protecting equipment, they are also used as safety measures to prevent any safety hazards to humans.

The fuse wire in an electrical fuse is selected in such a way that it does not face any damage when the normally stipulated amount of current flows through the circuit. Under normal conditions, the fuse wire is a part of the circuitry, contributing to a complete loop for charges to flow through it. However, when an excessive amount of current flows through the fuse wire, the heating effect of current causes the fuse wire to melt. This is because the fuse wire is chosen such that it has a low melting point. This causes the loop to break thereby stopping the flow of charges in the circuit.

It is important to select a fuse that is properly specified for the circuit in consideration. For example, if the fuse that is used is underrated, then it will fail even under normal current conditions, unnecessarily breaking the circuit loop. If it is overrated, then it will not break the circuit when required and cause equipment damage and failure and may even present itself as a safety hazard.

Information Sources: