Project work is an indispensable part to study practically running processing technology for a student in the College of Textile Technology. This enable us to avoid the gap between theories taught us just in the class room and its applicability in practice, every year the student of the college are assigned with a particular project work. This is very important in the sense that it is the assignment that a student or group students has to accomplish by themselves prior to their job life in any industry. This work may be of any type such as production, survey the mill data or may be analyses of the Textile or giving any particular property like dyeing, finishing effect to the textile material such as yarn or fabrics.

This really increases level of confidence of the students and also increases their knowledge about this field.

Our project work was estimated as

EFFECT OF DIFFERENT COUNT OF YARN ON GREY FABRIC PROPERTIES.

FLAMEPROOF FABRIC:

Flameproof fabrics are absolutely necessary for protective clothing in many industrial processes where the chances of inflammable fabrics being ignited are high. In the domestic sphere many serious and tragic accidents are the results of clothing catching fire, e.g. a dress is ignited when a young lady is powdering her face and using a mirror placed over the mantelpiece.

Some definitions and terms used relating to flammability

Flammable: A flammable fabric is one which propagates flame, i.e. it continues to burn after the igniting flame has been removed.

Flame-resistance rating: The time in seconds necessary for the propagation of flame 100 in. in a vertical strip.

Flame-proof: A flame-proof fabric is one which does not propagate flame, i.e. any flame goes out quickly when the igniting flame is withdrawn.

Flame-resistant: A Flame-resistant fabric is one whose flame-resistance rating is high, i.e. above 150.

Durably fame-proof material: Flame-proofed material which, after being submitted to a washing treatment, remains flame-proof.

Factors affecting flame-resistance:

Some general conclusions on the factors which affect the flame-resistance of fabrics are included in a report published by the British Standards Institution.

Fiber content: The flame-resistance of a fabric is partly dependent on the fiber from which it is made. Cellulosic fibers such as cotton, flax, and viscose rayon give fabrics of low flame-resistance; wool fabrics are usually difficult to ignite; nylons and Terylene, both thermoplastic fibers, shrink from the flame and tend not to ignite, although special stiffening treatments and certain dyes may result: in the flammability of nylons and Terylene.

Type of yarn: It has been found that for all practical purpose yarn structure in itself does not affect the flame-resistance of a fabric.

Fabric structure: The flame-resistance of a fabric appears to be largely independent of the manufacturing process by which it has been made, e.g. weaving, knitting, twisting, lace making, fiber bonding, felting.

Fabric weight: 1.For fabrics which propagate flame it has been found that flame-resistance is related to their weight as well as to their fiber content; for any given fiber, the heavier the fabric the higher will be its flame resistance.

2. For a given fiber the flame-resistance rating of a fabric has been found to be directly proportional to its weight in ounces per square yard; a 6 oz cotton fabric, for instance, will have twice the flame-resistance of a similar cotton fabric weighing 3 oz. The graphs in illustrate this relationship.

Introduction: The garments which come into contact with the body where perspiration is heavy may suffer serious local discoloration. This test is intended to determine the resistance of color of dyed textiles to the action of acid and alkali perspiration.

SDC recommended multifibre fabric to the test specimen and immersed into water, drained and placed between two plates under a specific pressure and time in a testing device. Any change in color of the specimen and staining of the multifibre fabric is then assessed with the corresponding Grey scales for color change and staining.

Definition of Absorbency:-

Absorbency is the ability of a fiber to take up moisture and is expressed as moisture region, which is the percentage of moisture that bone-dry fiber will absorb from the air under standard conditions of temperature and humidity.

The moisture regain of a fiber can be changed. For example on cotton fiber when mercerization is done, it increases cotton’s absorptive power and acetylation lower’s it. Absorbent fibers are hydrophilic or water loving while non-absorbent fibers are hydrophobic or water hating.

Related terms of absorbency

Water proof:

To treat textile material e.g. with fats, waxes or rubber, to prevent the absorption of water. The additions may be-

- Physical films

- Physical coatings

- Physical combined.

The feature of a water proof (fabric) is the low degree of permeability to air.

Shower proof:

To treat textile materials in a manner to delay the absorption and penetration of water. The fabrics retain a degree of permeability to air. The feature of a shower proof fabric is the normal degree of permeability but not properly water-proof.

Water repellent:

A state characterized by the non-spreading of a globule of water on a textile material.

Water retention:

This is the moisture remaining in and on a material after a specified mechanical treatment.

Wet ability:

According to British Cotton Industry Research Association(B.C.I.R.A):A drop of water (or sugar solution) is placed on the specimen which is mounted horizontally. The time taken for the contact angle to drop to 45 degree is noted the reciprocal of the time taken for this purpose is called the wetting velocity or wet ability.

Wetting Time:

The wetting time can be described by a test developed by Baxter and Cassie.A fabric stripe is immersed in water of 20.Then it is withdrawn from the water at a speed of 8mm/min.At the start of the test a large receding contact angle is seen but after sometime the angle is to decrease to 90.This time taken to decrease the angle to 90 is called the wetting time.

Stiffness: A fabric property to describe its resistance against deformation. Stiffness means resistance to bending. It can be measured by finding out the bending length or bending modulus or flexural rigidity. We used bending length for stiffness test. Shirley stiffness tester is used for this test.

Definition:

Reduction in length or width of a fiber ,yarn or other textile, induced by conditioning ,wetting, steaming , chemical treatment ,wet processing as in laundering, dry heat or mechanical action.

Shrinkage Tests:

A fabric would have great technical merit if its dimensions remained constant throughout its useful life. Suits would retain their shape and shirt would retain their size if fabrics could be produced which maintained their original finished settings. One very important dimensional is that which occurs when a fabric is washed. It is common practice to buy shirts and similar cloths a little on the large size in the hope that after a few washings they will have shrunk to the desired fit. It is not proposed to go into the theories of shrinking or the technology of its prevention, but it is necessary to define the different types of shrinkage.

Relaxation:

During manufacture, fabrics and their component yarns are subjected to applied tension under varying conditions of temperature and moisture content. In the finished state the fabric may be temporarily set in a stretched condition. When crimp was discussed earlier it was noted that such stretching upsets the balance of warp and weft way crimp percentages. The hot and wet conditions of washing allow the strains to relax and therefore the material shrinks.

Pilling Test

Definition:Pilling is fabric surface fault characterized by little pills of entangled fiber clinging to the cloth surface and giving the garments cloth surface and giving the garments an unlikely appearance.

The pills are formed during wear and washing by the entanglation of loose fibers which protrude from the fabric surface.

Effect of fibers and yarns construction on pilling:

Pilling is a characteristic of any man-made fibers. Fabrics containing fibers such as acrylic, nylon, or polyester have a tendency to pill. Abrasion from normal wear and cleaning causes the fibers to unravel and the loose ends ball up on the fabric surface. Natural fibers like cotton, linen, or wool may also pill at times, but the balls of fibers are usually removed during laundering.

When short staple fibers are used in the formation of yarns, the degree of twist is another important factor. Tightly twisted yarns composed of short staple fibers are considered more secure than loosely twisted yarns composed of short staple fibers. Usually the higher the twist of the individual fibers, the moiré securely they are bound and the less likely they are to pill.

Effect of construction of the fabric on pilling:

The construction of the fabric is also important in determining its susceptibility to pilling. A very tight, compact construction, such as denim, usually pills very little. However, a loosely knitted or woven fabric will show more pilling with both wear and cleaning. Pilling is often more noticeable on knitted fabrics, such as sweaters, than on woven. Lint often becomes tangled in the little balls of fiber which makes the pilling appear more obvious.

Causes of pilling:

1. Due to wear and finishing.

2. Due to rubbing action of fabrics with particular parts of a garment.

3. Due to soft twisted yarn.

4. Due to excess short fibers.

5. Due to migration of fibers from constituent yarn in fabric.

6. Yarn hairiness.

7. Due to heat formation of thermoplastic fibers.

8. Low denier of nylon filament.

Theory of crease resistance & recovery: Several terms are used to describe creasing characteristics of the fabric. Crease or wrinkle resistance means that a fabric resists bending twisting and other deformations.Crease recovery means that a fiber or fabric can bend and twist and then recover from this deformation. A fabric that resists bending when the body bend is less comfortable then one that gives and then recovers its original smoothness. Therefore crease recovery describes the performance that the consumer desires in a fabric. BOCK and MCCORD define crease resistance as that property of a fabric which causes it to recover from folding deformations that normally occur during its use. The recovery will depend on time varying for different fabric from an instantaneous recovery to a slow disappearance for the crease. Wrinkle may be regarded as fabric dimension which are not severe enough to produce crease.

Factors affecting crease recovery

Yarn structure:Yarn structure must be considered when a crease forms in a woven or Knitted fabric, the yarns bend. The fiber in the outer side of the yarn are strained, those on the inner side are compressed. Researchers who have investigated the factors of fabric structure related to crease resistance and recovery suggest that the following principles operate.

- The most important factor in the crease resistance is the freedom of the yarn and fibers to release. Loosely woven fabrics generally allow more fibers redistribution and motion and therefore have better crease recovery.

- Stiffer fabrics will become creased to a looser degree than will more flexible fabrics. Since greater pressure is required to form a crease in stiff fabrics. Stiff fabrics will form fewer wrinkles during washing and drying but once wrinkles have been formed wrinkle recovery is less than, it is far more flexible fabrics.

Strength of the bond and cross links:

Fabric crease recovery is depended on the resiliency of the fibers. Fiber resiliency is depended on the strength of the bond and cross link that hold the molecular chain together after a cloth is bend, thus preventing the formation of a wrinkle.

Definition:

Munden first suggested the use of a factor to indicate the relative tightness or looseness of plain weft knitted structure, to be used in a similar manner to that of the cover factor in the weaving industry. Originally termed the cover factor but now referred to as the tightness factor. Tightness factor, K is a number that indicates the extent to which the area of a knitted fabric is covered by the yarn. It is also an indication of the relative looseness or tightness of the knitting.

The ratio of the area covered by the yarn in one loop to the area occupied by that loop is called tightness factor (TF).

The total area covered by yarn is: S x l x d

Where,

l is loop length in mm.

d is yarn diameter in mm (assuming the yarn to have a circular cross section and the fabric to be theoretically flat and not three-dimensional).

The simplified formula is TF, K =

Where, l= Stitch length in SI unit.

Stitch Length:

Stitch length is defined as the length of yarn required to form a knitted loop. Stitch length is a length of yarn which includes the needle loop and half the sinker loop on either side of it. Generally the larger the stitch length, the more extensible and lighter the fabric and poorer the cover, opacity and bursting strength.

Stitch length = 1 needle loop + 1 sinker loop

Measurement of stitch length:

1. Off m/c: (In fabric)

- Hattra course length tester

- Shirley crimp tester

2. On m/c: (During knitting)

- Yarn speed meter

- Yarn length counter

The yarn length counter:

It is the simplest in construction providing a reading of the amount of yarn feed in a certain time period. It is particularly suitable for attaching to a moving yarn feeder on a circular revolving cam box m/c. After a specific number of revolution, the machine is stopped to enable the yarn length reading to be taken; this is then divided by the number of knitting m/c revolution in order to obtain the course length for that feed.

The yarn speed meter:

It may calibrate & provides a direct reading of the rate of yarn feed, usually in meters per minute, whilst the machine is running. The meter may be hand-held and can be used on a revolving cylinder m/c without the need to stop it. To obtain the course length it is necessary to divide the reading by the number of knitting m/c revolutions per minute.

Object:

i)To calculate the no. of Wales per inch.

ii) Calculation of course per inch.

Fabric weight per unit area and unit length:

The weight of a fabric can be described in two ways. One s the weight per unit area other is the weight per unit length. In fabric descriptions, the weight per unit length is usually referred as the weight per running yards. It is necessary therefore to know the agreed standard width upon which the weight per running yard is based.

Definition:

1. The ability of a material to resist rupture by pressure.

2.The force required to rupture a fabric by distending it with a force applied at right angles to the plane of the fabric under specified conditions. Burst strength is a measure widely used for knit fabrics, nonwoven fabrics, and felts where the constructions do not lend themselves to tensile tests. The two basic types of burst tests are the inflated diaphragm method and the ball-burst method.

Method used:By A.S.T.M(American Society For Testing Materials)

Methods of measuring threads per inch:

1) one inch counting glass-a simple microscope

2) traversing thread counter – a traveling microscope filled with a pointer to aid counting

3) Fabric dissection – a known width is unraveled and the threads are difficult to distinguish.

4) Parallel line gratings – a rapid optical method.

5) Taper line grafting – a development of no Parallel line gratings.

conditioning time – 24 hrs

conditioning time – 24 hrs

The 1 inch counting glass is not recommended when the number of threads per inch is less than 25. In each case, a 3 inch sample could be unraveled and the treads counted.

In the specification it will be noted that specimen should be conditioned for at least 24 hours before testing. The regions near the selvedges should be avoided because the spacing of the threads is often a little different than in the body of the cloth.

Apparatus:

1. one inch counting glass

2. Needle

3. Pencil

Sample:

Grey knitted fabric-

1. Single jersey

2. Rib

3. Interlock

Procedure:

i) At first set the counting glass at the desired position.

ii) Then count the Wales or coarse with needle through the counting glass..

Method used: By A.S.T.M

Methods:

- G.S.M cutter

- Quadrant balance- count/100 yds²

d = 1/28

πr² = 3.14 x (1128/2)²

= 99.882

Objective:

- To determine the gsm of the given sample of fabric

- To compare the gsm of fabric

Apparatus:

1) Template

2) Quadrant balance

3) Scissor

4)GSM cutter

5) Electric balance

Sample:

1) Grey cotton knitted fabric

- Single jersey

- rib

- interlock

Machine specification:

- Name: G.S.M cutter.

- Brand: Good brand & co. ltd

- Scale: 100 yds for fabric

Procedure:

1) For measuring gsm we should cut the fabric sample by gsm cutter. By this way cut 10 knitted samples.

2) Now weight this sample by electric balance.

3) By this way we get the weight in gm per square

meter.

4) Now find out the average of this found weight.

Method Used: By A.S.T.M

Method of Bursting Strength test:

- Hydraulic bursting strength testing method

- Mechanical bursting strength testing method

We used Hydraulic bursting strength testing method for the grey fabric samples.

We used Hydraulic bursting strength testing method for the grey fabric samples.

Atmospheric condition:

Temp.- 25 c

Relative Humidity- 65%

Apparatus required:

1.Hydraulic bursting strength tester (Truburst-James H Heal& Co.Ltd)

2.Grey fabric

Test area-50cm square (79.8 mm dia)

Clamping-6.0 bar

Pressure rate-10 KPa/s

Pressure drop- 10.00 KPa

Diaphragm- 1.0 mm Duraflex

Procedure:

- At first required shaped samples are taken.

- Then samples are kept on the diaphragm.

- Now the plastic lid is kept on the sample in order to make it air tight.

- Then the m/c is started to create required pressure to burst the sample.

- Then the readings are taken from the monitor.

Method used: By A.S.T.M

Method of the Test of Flammability:

- Vertical strip Test

- The visual Timing Test

- The Hoop Test

- The 45° Test

Working procedure of Vertical strip test:

- The rate of propagation of the flame is measured in terms of the distance is millimeters per minute that the base of flame travels up a strip 30 cm long and 2.5 cm wide.

- The time to travel between two markers 17cm apart is observed.

Method used: By A.S.T.M

Method of Perspiration Test:

Color fastness to Perspiration

Apparatus:

- SDC recommended multi-fibre fabric

- perspirometer

- Non-dyeable fabric (eg.Polypropylene)

- acid & alkali solution

- Grey scale for color changing

- Grey scale for staining

- oven (to maintain temp of 37+20C)

- glass or Acrylic plates.

- Standerd lighting chamber

Recipe for perspiration:

Alkali solution

Disodium hydrogen orthophosphate dihydrate :2.5gm/L

L-histadine monohydrochloric hydrate :0.5gm/L

Common salt :5gm/L

PH :8

Acid Solution

Disodium hydrogen orthophosphate dihydrate :2.2gm/L

L-histadine monohydrochloric hydrate :0.5gm/L

Common salt :5gm/L

PH :5.5

Sample preparation:

The tested sample is prepared as below:

- A 10cm × 4 cm grey fabric sample to be tested is taken.

- Another two pieces of fabric sample which are scoured, bleached but unfinished same dimension sample is also taken.

- One of the unfinished samples will be of same fibre of the tested sample. Another sample’s fibre type will depend on the type of fibre constitute the tested sample. Here we tested cotton sample and the two other fabric is cotton and multi fibre fabric.

- Now the tested sample is placed between the unfinished samples covering and sewn together.

Test procedure:

- Immerse each composite specimen in acid or alkali solution in a beaker for 30mins at room temperature, ensure that the specimen are thoroughly wetted out by agitating the samples with stirring rod, Liquor ratio 1:50.

- Place the specimen into a resin acrylic or glass plate and draw across with the stirring rod to remove any air bubbles. Place another resin plate (acrylic plate) on top of the specimens to fully enclose it with fabrics uppermost. Place a max ten specimens, ensuing that each specimen is separated by one resin plate.

- Bring the upper pressure plate of the perspirometer down to rest on top of the resin plates and place the 4.5 kg wt on to the pressure plate and tighten the securing screws. This is equal to the pressure of 12.5KPa being applied on the specimens.

- Now place the specimen into a oven at 37+20C / below 60OC for 4hours.

- On completion of the test, remove the specimen from the oven & separate them from the resin plates.

Interpretation of result:

Change in colour– From portion of sample change in color is compared with the untreated dyed sample on contrast basis with the help of grey scale. The grade of contrast in grey scale is the water fastness of the sample.

Staining – The staining is measured by staining grey scale. Here the staining of unfinished sample is compared with the original untreated unfinished sample from staining grey scale on the basis of contrast.

Method followed: By A.S.T.M

Methods of testing:

- The wetting time test.

- The spray test.

- The drop test or drop penetration test.

- The Bundesmann test.

- Shirley Hydrostatic head test.

The Spray Test:

Working Principle:

- In this test a small scale mock rain shower is produced by pouring water through a spray nozzle. The water falls on to specimen which is mounted over a 6 inch diameter embroidery hoop and fixed at an angle of 45 degree.

- To carry out the test,250 of water at 70 are poured steadily into the funnel for 25-30 sec.

- After spraying has finished the sample holder is removed and the surplus water removed by tapping the frame six times against a solid object.

- The assessment of the fabrics water repellency is given the spray rating.After the removal of the surplus water is accomplished the fabric surface is examined visually.

- The American Association of Textile Chemists and colorists recommended the use of a chart of photographs against which the actual fabric appearance is compared. The ratings are as follows

90 →Slight random sticking or wetting of the upper surface .

80 →Wetting of upper surface at spray point.

70 →Partial wetting of water of upper surface.

50 →Complete wetting of whole of upper surface.

0 →Complete wetting of whole of upper and lower surface.

Seven test should be made and the nearest rating assigned to each since no interpolation is allowed i.e. a raining for a specimen can not be is 75.The mean of seven ratings is reported.

Method followed: By A.S.T.M

Methods of stiffness test:

- The Shirley stiffness tester

- The heart loop tester

- The Drape meter

Bending length:

This is the length of fabric that will bend under its own weight to a definite extent. It is a measure of the stiffness that determines draping quality.

Basic principle of Shirley stiffness tester:

A rectangular strip of fabric, 6 inchx1 inches, is mounted on a horizontal platform in such a way that it over laps likes a cantilever & bends downwards. From the unsupported length (l) & the bending angle (Ө), the value of bending length(c) can be determined, which indicate the stiffness of the fabric. If the bending length is more than the fabric will be stiff more & vice versa. The bending length can immediately be read off from the scale mark opposite a zero line engraved on the side of the platform.

Each specimen is tested seven times at each end & again with the strip turned over.

Mean values for the bending length in courses & Wales direction can then be calculated.

Method followed: By A.S.T.M

Sample size: Interlock- 30×30 cm,

RIB & S/J- 15X15 cm

Testing for shrinkage:

It is logical to assume that the shrinkage test on a particular type of material should put the fabric through a washing procedure similar to that which it would go through in practice. The wide variety of fabrics on the market today encourages the manufacturers of soaps and detergents to issue washing instructions for the different types of material.

The principles of shrinkage tests are simple but it is necessary to follow the standard procedures in order to obtain comparative results.

The principles of shrinkage tests are simple but it is necessary to follow the standard procedures in order to obtain comparative results.

Essentially, the tests are carried out in the following stages:

1. Preparation of specimens: The fabric should be conditioned in a standard testing atmosphere before marking out. Usually three pairs of datum line are marks out in each direction. The marking out may be done with ink or with sewing thread.

2. Washing: The sample in the relevant washing solution in a washing machine conforming to certain specifications. After the specified time has elapsed the sample is rinsed.

3. Drying: After rinsing the surplus water is removed by centrifuge or by hand squeezing or rolling in toweling. Drying is completed by means of a flat-heated press or a heated flat iron.

4. Conditioning and re measuring: After drying, the specimen is conditioned in a standard testing atmosphere and the distances between the datum line measured.

Percentage shrinkage:

This is calculated from the mean changes in the distance between the datum lines. Percentage shrinkage= S=

Where,

L.B.W. is the distance between the datum lines before washing and

L.A.W. is the distance between the datum lines after washing.

Method followed: By A.S.T.M

Method of pilling test:

1. The Martindale Abrasion Tester

2. Braid, Hat field and Morris’s pill tester

3. The ICI Pilling box test

4. The Du-Pont random pilling Tester

- At the end of the time period allowed for recovery, usually 1 min the recovery angle in degrees is reed on the engraved scale.

- Course and Wales way recovery are reported separately to the nearest degree from the mean values of seven testes.

Instrument Used for stitch length:

Stitch length meter

Procedure:

- First collect the length of yarn feeding in meter during knitting in required revolution.

- Find the average.

- Multiply by 1000 to convert in mm.

- Divide by the number of needle.

- Divide by revolution number.

- Then we find the Stitch Length.

Causes of stiffness test result variation:

Causes of stiffness test result variation:

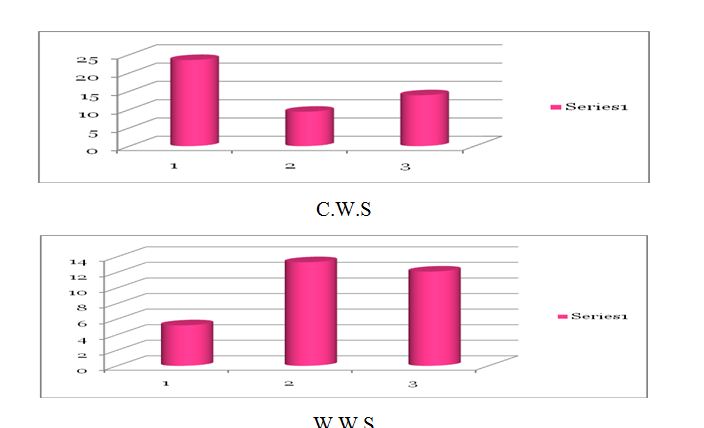

We have used grey fabric (cotton) in case of testing procedures. Bending length of interlock fabric is most so stiffness also most among three fabric, because interlock fabric is double thicker than single jersey made from the same count’s yarn. Rib fabric is less stiff than interlock because it has vertical cord appearance. For single jersey the test can not be continued for the curling tendency.

Causes of shrinkage test result variation:

Single jersey fabric is the most relaxed structure among three fabrics. For this reason in a average it has maximum shrinkage. On the other hand interlock has less shrinkage than single jersey because; it has single jersey structure on both side of the fabric. Due to vertical cord effect rib has the lowest shrinkage rate.

CONCLUSIONS

In this study, with some of the experiments it was seen the properties of the fabric dependent on the yarn count whereas some of them were independent of the yarn count. We used unfinished fabric so we cannot say how the count of yarn will affect the properties in case of a finished fabric. But this project gives us a primary idea how the fabric may behave in the future. It also helps us to determine the types finishing to be applied on a fabric.

Limitations of the Study:

Like all other scientific work, this study has its own limitations. Due to lack of time and money we couldn’t use better facilities to determine the effect of yarn count more accurately.

All other parameters that can affect the properties of fabric has been tried to kept constant. But since all the tests have been performed by inexperienced students, this cannot be claimed that we had been able to do that. There is more scope to work on the topic in future and there should be an ongoing research .