Quality based organizations should strive to achieve perfection by continuously improving the business and production processes. Of course, perfection is impossible because the race is never over; however, we must continually strive for its attainment.Continuous Process Improvement in the front office might be the elimination of steps in an order review and entry process where it can be determined .Here implementing continuous process improvement:

- Plan: Identify an opportunity and plan for change.

- Do: Implement the change on a small scale.

- Check: Use data to analyze the results of the change and determine whether it made a difference.

- Act: If the change was successful, implement it on a wider scale and continuously assess your results. If the change did not work, begin the cycle again.

Improvement is made by-

- Viewing all work as a process, whether it is associated with production or business activities.

- Making all processes effective, efficient, and adaptable.

- Anticipating changing customer needs.

- Controlling in process performance using measures such as scrap reduction, cycle time, control charts, and so forth.

- Maintaining constructive dissatisfaction with the present level of performance.

- Eliminating waste and rework wherever it occurs.

- Investigating activities that do not add value to the product or service, with the aim of eliminating those activities.

- Eliminating nonconformities in all phases of everyone’s work, even if the increment of improvement is small.

- Using benchmarking to improve competitive advantage.

- Innovating to achieve breakthroughs.

- Incorporating lessons learned into future activities.

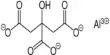

- Using technical tools such as statistical process control (SPC), experimental design, benchmarking, quality function deployment (QFD), and so forth.