Concrete formwork removal, also known as strike-off or stripping of formwork, should only be done once the concrete has developed adequate strength, which is at least twice as much stress as the concrete may experience when the formworks are removed. During the dismantling of the formwork, it is also essential to guarantee the stability of the remaining formwork.

Concrete Formwork Removal Time

The velocity of concrete hardening or the strength of the concrete are temperature-dependent and have an impact on how quickly the formwork is removed. For instance, it will take longer to remove concrete in the winter than it will in the summer.

Flexural elements like beams and slabs must be removed from formwork with special care. These members may deflect if the strength acquired is insufficient to handle the stresses since they are still vulnerable to self-load and live loads during construction.

Concrete cube or cylinder tests should be performed to determine the strength of the concrete prior to formwork removal. The concrete cubes or cylinders should be made from the same mix as the structural members and should be dried in conditions that are similar to those of the structural members in terms of temperature and moisture.

Formworks should only be removed once it is certain that the concrete in the structural components has become strong enough to resist the design load. The formworks should be left for as long as possible because doing so aids in curing.

Removal of formwork from the concrete section should not make the structural element to:

- Collapse under self load or under design load

- deflect the structural member excessively in short or the long term

- physically damage the structural member when formwork is removed.

The following points must be kept in mind during formwork removal whether the structure will be prone to:

- freeze thaw damage

- cracks formation due to thermal contraction of concreteafter formwork striking.

Delaying the removal of the formwork is preferable if there is a considerable chance of any of the aforementioned damages. Formwork must be properly insulated in order to prevent damage if it needs to be removed in order to optimize concrete construction processes.

Calculation of Safe Formwork Striking Times:

Structural members are constructed based on designed load. But during the construction phase, structural elements are subjected to their own weight and construction loads before a structure is finished and exposed to all of the stresses assumed during structural design.

The behavior of the structure under its own load and the load of construction must therefore be calculated in order to move construction operations along more quickly. Formwork may be removed if this is successful and a structural part is determined to be secure.

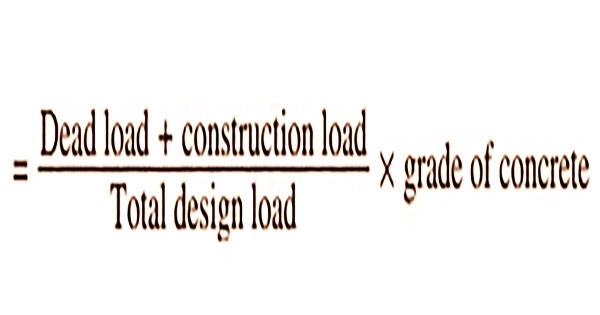

If these calculations are not possible, then following formula can be used for calculation of safe formwork striking times:

Characteristic strength of cube of equal of maturity to the structure required at time of formwork removal

This formula was given by Harrison (1995) which describes in detail the background of determination of formwork removal times.

Other method to determine the strength of concrete structure is to conduct the non-destructive tests on structural member.

Factors Affecting Concrete Formwork Striking Times

The striking time of concrete formwork depends on the strength of structural member. The strength development of concrete member depends on:

- Grade of concrete – higher the grade of concrete, the rate of development of strength is higher and thus concrete achieves the strength in shorter time.

- Grade of cement – Higher cement grade makes the concrete achieve higher strength in shorter time.

- Type of Cement – Type of cement affects the strength development of concrete. For example, rapid hardening cement have higher strength gain in shorter period than the Ordinary Portland Cement. Low heat cement takes more time to gain sufficient strength than OPC.

- Temperature – The higher temperature of concrete during placement makes it achieve higher strength in shorter times. During winter, the concrete strength gain time gets prolonged.

- A higher ambient temperature makes the concrete gain strength faster.

- Formwork helps the concrete to insulate it from surrounding, so longer the formwork remain with concrete, the less is the loss of heat of hydration and rate of strength gain is high.

- Size of the concrete member also affects the gain of concrete strength. Larger concrete section members gain strength in shorter time than smaller sections.

- Accelerated curing is also a method to increase the strength gain rate with the application of heat.

During stripping of formwork, following points must be remembered:

- Before the concrete has gained the necessary strength to support all weights imposed upon it, the formwork should not be removed. The amount of time needed before formwork can be removed depends on the member’s structural function and the rate at which the concrete gains strength. The rate at which concrete gains strength depends on factors such as concrete quality, cement type, water-to-cement ratio, curing temperature, etc.

- The formwork components and connections should be set up so that it may be reused without requiring major maintenance, is simple and easy to remove, and doesn’t damage the concrete or the formwork panels.

- To ensure that the quality of hardened concrete in structural members, i.e., that it is free from or has a minimum amount of casting flaws such as honeycombing, size and shape defects, etc., the formwork removal method should be under the engineer’s supervision. The strength and stability of the structure are impacted by these concrete flaws. Therefore, urgent repairs can be made, or the members can be dismissed.

- The separation of forms should not be done by forcing crowbars against the concrete. It may damage the hardened concrete. This should be achieved by using wooden wedges.

- Beam and joist bottoms should remain in place until final removal of all shoring under them are done.

- It is advisable to design and remove joist forms so that they can be temporarily removed to provide room for their removal, but that they must immediately be rebuilt. Starting at the centre of the member’s span and moving symmetrically up the supports, the coasts and joists will be taken apart.

- The approval from the engineer should be obtained for the sequence and pattern of formwork removal.