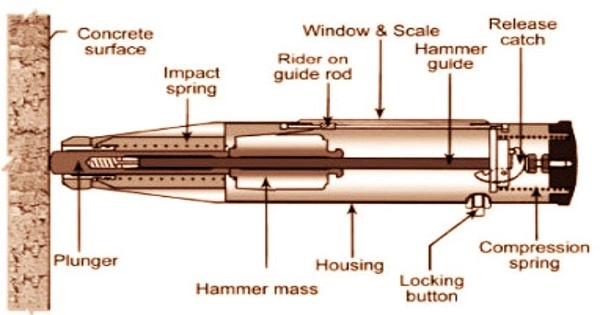

Rebound Hammer testing is a non-destructive method of determining the compressive strength of concrete that offers an easy-to-use and quick indication. The rebound hammer, which is also known as a Schmidt hammer, is made out of a mass controlled by a spring that travels along a plunger inside of a tubular housing.

A spring-controlled mass with consistent energy is made to hit the surface of the concrete when the plunger of the rebound hammer is pressed against it. On a graded scale, the amount of rebound, which measures surface hardness, is measured. This measured value is designated as Rebound Number (rebound index). A concrete with low strength and low stiffness will absorb more energy to yield in a lower rebound value.

Objective of Rebound Hammer Test

The rebound hammer test have the following objectives:

- To determine the compressive strength of the concrete by relating the rebound index and the compressive strength

- To assess the uniformity of the concrete

- To assess the quality of the concrete based on the standard specifications

- To relate one concrete element with other in terms of quality

The rebound hammer test method can be used to distinguish between the structure’s acceptable and dubious components or to compare the strengths of two different structures.

Principle of Rebound Hammer Test

The premise behind the rebound hammer test method is that an elastic mass’ ability to rebound is dependent on how hard the concrete surface it strikes is. The spring-controlled mass in the rebound hammer bounces back when the plunger is pressed against the concrete surface. The hardness of the concrete surface affects how much the mass bounces back.

As a result, the compressive strength of concrete can be connected to the rebound hammer reading and hardness of concrete. The rebound value, also known as the rebound number or rebound index, is read off along a graded scale. Direct reading of the compressive strength is possible from the graph located on the hammer’s body.

Procedure for Rebound Hammer Test

Procedure for rebound hammer test on concrete structure starts with calibration of the rebound hammer. For this, the rebound hammer is tested against the test anvil made of steel having Brinell hardness number of about 5000 N/mm2.

The rebound hammer is held at a right angle to the surface of the concrete construction for taking the readings after being checked for accuracy on the test anvil. For various purposes, the rebound hammer requires a variable amount of impact energy.

Correlation between compressive strength of concrete and rebound number

The best way to determine the relationship between the compressive strength of concrete and rebound number is to test the concrete cubes concurrently using a compression testing machine and a rebound hammer.

Concrete cube rebound is measured first, and then the compressive strength is assessed using a compression testing machine. When the hammer’s impact energy is around 2.2 Nm, the fixed load that is needed is of the order of 7 N/mm2. When calibrating rebound hammers with a higher impact energy, the load should be increased, and when calibrating rebound hammers with a lower impact energy, the load should be dropped.

The test specimens should be as large a mass as possible in order to minimize the size effect on the test result of a full scale structure. 150mm cube specimens are preferred for calibrating rebound hammers of lower impact energy (2.2Nm), whereas for rebound hammers of higher impact energy, for example 30 Nm, the test cubes should not be smaller than 300mm.

After removing the concrete cube samples from the curing pond, they should be maintained at room temperature for roughly 24 hours before being tested with a rebound hammer. It is required to develop a link between the strength of wet tested cubes and the strength of dry tested cubes on which rebound readings are collected in order to achieve a relationship between rebound numbers and the strength of wet cured and wet tested cubes.

It is not advised to draw a conclusion about the strength of wet cubes based solely on the rebound values on wet cubes. The cubes as cast should only have their vertical faces examined. When employing the rebound hammers, at least nine readings must be taken on each of the two vertical faces that are accessible in the compression testing machine. The points of impact on the specimen must not be nearer an edge than 20mm and should be not less than 20mm from each other. The same points must not be impacted more than once.

Interpretation of Rebound Hammer Test Results

The strength of the structure can be evaluated after determining the link between compressive strength and rebound number. In general, the rebound number rises as the strength rises and is also influenced by a variety of factors, such as the kind of cement, the type of aggregate, the moisture content and condition of the concrete’s surface, the concrete’s age and curing, the amount of carbonation on the surface, etc.

Additionally, the rebound index provides insight into the concrete’s compressive strength up to a certain depth from the surface. Rebound figures won’t show the cross-sectional variability or internal cracks, defects, etc.

As such the estimation of strength of concrete by rebound hammer method cannot be held to be very accurate and probable accuracy of prediction of concrete strength in a structure is ± 25 percent. The accuracy of results and confidence in them are substantially strengthened if tests on core samples taken from the structure or standard specimens constructed with the same concrete ingredients and mix percentage can be used to determine the link between rebound index and compressive strength.