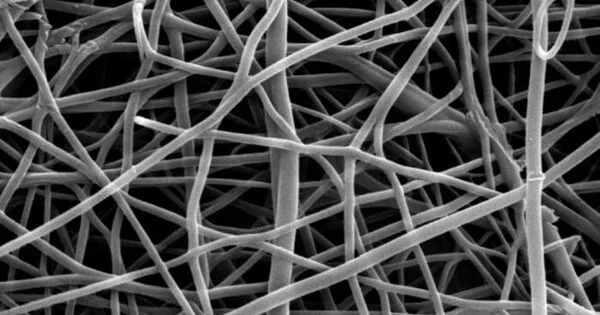

Carbon nanofibers (CNFs), also known as vapor-generated carbon fibers (VGCFs) or vapor-grown carbon nanofibers (VGCNFs), are cylindrical nanostructures made up of graphene layers arrayed in the shape of stacked cones, cups, or plates. These are nanomaterials that are predominantly made up of carbon atoms organized in a fibrous form.

Carbon nanotubes are formed by wrapping carbon nanofibers with graphene layers into flawless cylinders. Their small size and high aspect ratio, with diameters typically on the nanometer scale (thus the name), distinguish them. CNFs are a subset of carbon nanotubes (CNTs), a well-known carbon nanomaterial.

Carbon nanofibers can be created using a variety of techniques such as chemical vapor deposition (CVD), electrospinning, and other catalytic processes. The technique of manufacture can affect features such as diameter, length, and alignment.

Here are some key features of carbon nanofibers:

- Structure: CNFs are typically composed of numerous graphene layers that are stacked concentrically around a hollow core. They have outstanding mechanical, thermal, and electrical qualities because to their unique structure.

- Mechanical Properties: CNFs have exceptional mechanical qualities, including as high tensile strength and modulus. They are frequently used to improve the mechanical performance of composite materials. Aerospace materials, sports equipment, and automobile components are examples of such applications.

- Thermal Conductivity: CNFs have excellent thermal conductivity, which makes them suitable for applications where efficient heat transfer is essential. They can be used as thermal interface materials, in electronics for heat dissipation, and in thermal management systems.

- Electrical Conductivity: CNFs are also good electrical conductors. This property has led to their use in conductive composites, sensors, and various electronic applications.

- Energy Storage: These have the potential to be employed as electrodes in energy storage devices like supercapacitors and lithium-ion batteries. These applications benefit from their high surface area and electrical conductivity.

- Catalysis: Because of their great surface area and stability, CNFs can act as catalytic supports. They are employed in a variety of catalytic processes, such as fuel cells and chemical reactions.

- Reinforcement: CNFs are frequently utilized as reinforcing agents in composites, including polymer, metal, and ceramic matrices, in addition to being employed as independent materials. This reinforcement increases the composite’s mechanical, thermal, and electrical properties.

Application

- Biomedical Applications: CNFs have shown promise in biomedical applications, including drug delivery, tissue engineering, and as substrates for cell growth due to their biocompatibility and unique properties.

- Environmental Applications: These are being explored for environmental remediation applications, such as water purification and air filtration, due to their high surface area and adsorption capabilities.