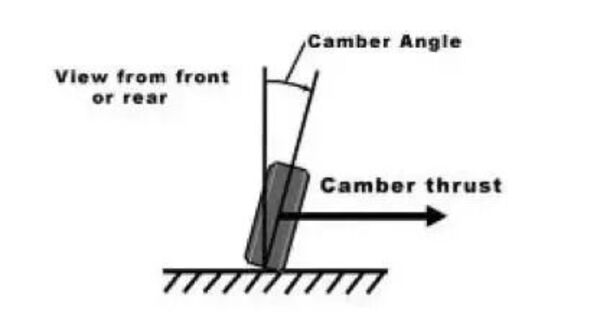

Camber thrust and camber force are phrases used to describe the force generated perpendicular to a rolling tire’s direction of travel as a result of its camber angle and limited contact patch. It is a vehicle dynamics phenomenon that is very relevant in the field of automotive engineering. It refers to the lateral force produced when a tire with camber (an angle between the tire’s vertical axis and the plane of the wheel) rolls over a flat surface.

When a tire is subjected to lateral force, such as cornering or steering, the contact patch deforms. If the tire has camber, the deformation produces a lateral force component perpendicular to the direction of movement. This force is known as camber thrust.

Camber thrust is produced when a point on the outer surface of a tilted and rotating tire, which would ordinarily follow an elliptical path when projected onto the ground, is forced to follow a straight path when in contact with the ground due to friction. This deviation towards the lean generates deformation in the tire tread and carcass, which is transferred to the vehicle as a force in the lean direction.

Camber thrust is almost directly proportional to camber angle for small angles, achieves its steady-state value nearly quickly following a change in camber angle, and hence does not have a relaxation time. Bias-ply tires are known to create more camber push than radial tires.

Camber stiffness is a measure that describes the camber thrust produced by a tire and is affected by inflation pressure and normal load. The net camber thrust is often located in front of the wheel’s center, resulting in camber torque, twisting torque, or twisting moment. This torque is oriented in such a way that it tends to drive a tire in the direction of its lean. An alternative explanation for this torque is that the two sides of the contact patch are at opposite radii from the axle, causing them to drive forward at different speeds unless restrained by pavement friction.

Camber thrust is an important factor in vehicle handling dynamics, especially in racing and high-performance automobiles. Engineers can modify the camber angle of the tires to control the amount of camber thrust generated, which influences the vehicle’s cornering performance, stability, and overall handling qualities. Camber angles can be properly tuned to improve grip and traction, hence enhancing the vehicle’s maneuvering capabilities.