Acoustic fabric refers to a type of specialized textile material designed to absorb sound waves and reduce echo or reverberation in a space. It is commonly used in various applications where controlling the acoustic environment is important, such as recording studios, home theaters, auditoriums, conference rooms, and restaurants.

Having trouble hearing? Just turn up your shirt. That is the idea behind a new “acoustic fabric” developed by engineers at MIT and collaborators at Rhode Island School of Design.

The group has created a material that functions like a microphone, transforming sound first into mechanical vibrations and then into electrical signals, much like how our ears perceive sound.

Although these vibrations are on a nanoscale scale, much too small to be normally felt, all fabrics vibrate in reaction to auditory stimuli. The researchers developed a flexible fiber that, when woven into a fabric, bends with the cloth like seaweed on the ocean’s surface in order to catch these undetectable signals.

The fabric may convert sound waves into electrical impulses because to the fiber’s use of a “piezoelectric” substance, which generates an electrical signal when bent or mechanically deformed.

The material can record sounds of all decibel levels, from those of a quiet library to those of busy roads, and can pinpoint the precise location of abrupt sounds like handclaps. The fabric may recognize a wearer’s minute heartbeat characteristics when it is woven into the lining of a shirt. Another fabric may be able to detect sound produced by the fibers, such as a recording of spoken words.

A study detailing the team’s design appears in Nature. Lead author Wei Yan, who helped develop the fiber as an MIT postdoc, sees many uses for fabrics that hear.

“Wearing an acoustic garment, you might talk through it to answer phone calls and communicate with others,” says Yan, who is now an assistant professor at the Nanyang Technological University in Singapore. “In addition, this fabric can imperceptibly interface with the human skin, enabling wearers to monitor their heart and respiratory condition in a comfortable, continuous, real-time, and long-term manner.”

The learnings of this research offers quite literally a new way for fabrics to listen to our body and to the surrounding environment. The dedication of our students, postdocs and staff to advancing research which has always marveled me is especially relevant to this work, which was carried out during the pandemic.

Yoel Fink

Yan’s co-authors include Grace Noel, Gabriel Loke, Tural Khudiyev, Juliette Marion, Juliana Cherston, Atharva Sahasrabudhe, Joao Wilbert, Irmandy Wicaksono, and professors John Joannopoulos and Yoel Fink at MIT, along with collaborators from the Rhode Island School of Design (RISD), Lei Zhu from Case Western Reserve University, Chu Ma from the University of Wisconsin at Madison, and Reed Hoyt of the U.S. Army Research Institute of Environmental Medicine.

Sound layering

The traditional use of fabrics to muffle or lessen sound includes soundproofing in performance halls and carpeting in our homes. However, Fink and his team have been working to alter the traditional duties of fabric for years. They concentrate on extending material qualities to provide fabrics more functionality. The team looked to the human ear for ideas on how to create sound-sensing materials.

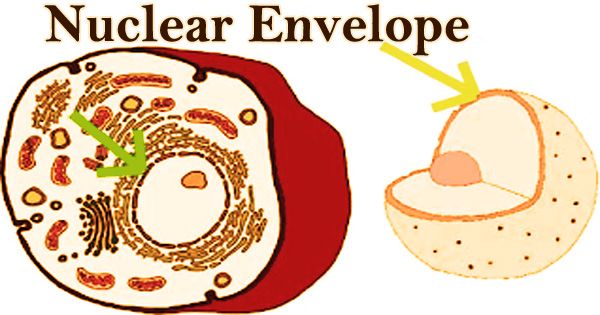

Audible sound travels through air as slight pressure waves. The tympanic membrane, often known as the eardrum, is a delicately sensitive and intricate three-dimensional organ that converts pressure waves into mechanical vibrations as they reach our ears. These vibrations pass through tiny bones and enter the inner ear, where the cochlea transforms them into electrical impulses that the brain can detect and comprehend.

The team set out to develop a fabric “ear” that would be soft, resilient, comfortable, and capable of detecting sound, drawing inspiration from the human auditory system. They made two significant discoveries as a result of their research: First, in order to properly transform sound waves into vibrations, such a fabric would need to have stiff, or “high-modulus,” threads. Additionally, the group would have to create a fiber that could flex with the fabric while still producing an electrical output.

The researchers created a preform, a stacked block of materials made of a piezoelectric layer and components to increase the material’s vibrations in response to sound waves, keeping these parameters in mind. After being heated, the resulting preform which was roughly the size of a thick marker was twisted into thin, 40-meter-long threads much like taffy.

Lightweight listening

By fastening the fiber to a suspended sheet of mylar, the researchers were able to assess the fiber’s receptivity to sound. They measured the vibration of the sheet and, consequently, the fiber using a laser in reaction to sound coming from a nearby speaker.

The decibel level fluctuated between that of a calm library and noisy traffic. The fiber vibrated in response, producing an electric current corresponding to the sound that was being played.

“This shows that the performance of the fiber on the membrane is comparable to a handheld microphone,” Noel says.

The fiber was then woven with regular yarns to create panels of drape- and machine-washable fabric.

“It feels almost like a lightweight jacket lighter than denim, but heavier than a dress shirt,” says co-author Elizabeth Meiklejohn, an RISD graduate student who wove the fabric using a standard loom.

The crew evaluated the fabric’s sensitivity to directional sound by clapping their hands while standing at various angles to the garment after she attached one panel to the back of it.

“The fabric was able to detect the angle of the sound to within 1 degree at a distance of 3 meters away,” Noel notes.

A directional sound-sensing cloth, according to the researchers, might make it easier for those who have hearing loss to focus on a speaker in noisy environments.

The team also successfully identified the heartbeat of a healthy volunteer and minute fluctuations in the S1 and S2 or “lub-dub” properties of the heart by stitching a single fiber to the inner lining of a shirt, just over the chest area. Fink sees opportunities for putting the acoustic fabric into maternity apparel to assist in monitoring a baby’s fetal heartbeat in addition to one’s own heartbeat.

Finally, the scientists switched the fiber’s use from being a sound detector to a speaker. They captured a series of spoken syllables, and then fed the recording in the form of an applied voltage to the fiber. The fiber transformed the electrical impulses into aural vibrations that another fiber could pick up on.

The team envisions uses for wearable technology beyond clothing, such as wearing hearing aids, clothes that interact, and gear that monitors vital indicators.

“It can be integrated with spacecraft skin to listen to (accumulating) space dust, or embedded into buildings to detect cracks or strains,” Yan proposes. “It can even be woven into a smart net to monitor fish in the ocean. The fiber is opening widespread opportunities.”

“The learnings of this research offers quite literally a new way for fabrics to listen to our body and to the surrounding environment,” Fink says. “The dedication of our students, postdocs and staff to advancing research which has always marveled me is especially relevant to this work, which was carried out during the pandemic.”

This research was supported in part by the US Army Research Office through the Institute for Soldier Nanotechnologies, National Science Foundation, Sea Grant NOAA.