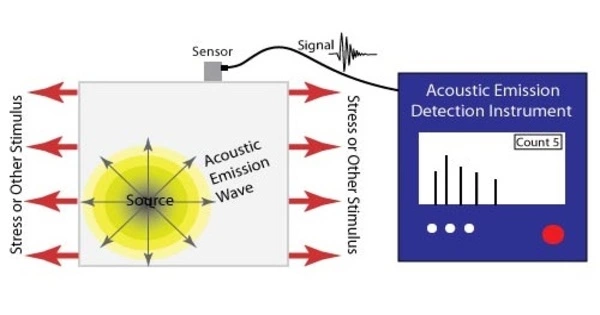

Acoustic emission (AE) is the phenomenon of acoustic (elastic) wave radiation in solids that occurs when a material’s internal structure undergoes irreversible changes, such as crack formation or plastic deformation caused by aging, temperature gradients, or external mechanical forces. It is the generation and detection of stress waves or acoustic waves in materials and structures as a result of internal changes or damage.

AE occurs most commonly during the mechanical loading of materials and structures, which is accompanied by structural changes that generate local sources of elastic waves. This causes minor surface displacements of a material caused by elastic or stress waves formed when collected elastic energy in a material or on its surface is abruptly released. It is a non-destructive testing (NDT) technique that is used to monitor and inspect the structural integrity of diverse materials such as metals, composites, concrete, and others.

The waves produced by AE sources are used in structural health monitoring (SHM), quality control, system feedback, process monitoring, and other domains. AE is commonly used in SHM applications to detect, localize, and characterize damage. In a variety of applications, including aerospace, civil engineering, manufacturing, and oil and gas, AE is particularly valuable for identifying and monitoring the advancement of defects such as cracks, corrosion, and delaminations.

Key points about acoustic emission:

- Generation: When the stress within a material crosses a specific threshold, energy in the form of elastic waves is released. This can occur as a result of a variety of reasons, including applied loads, thermal strains, and material flaws.

- Detection: The acoustic waves produced by these occurrences are detected and recorded using devices known as AE transducers or sensors. Mechanical vibrations are converted into electrical impulses that may be examined by these sensors.

- Analysis: The collected AE signals are analyzed to obtain useful information regarding the source of acoustic emissions, such as its location, magnitude, and characteristics. To discriminate between different sorts of events and estimate their significance, sophisticated data analysis techniques are used.

Applications

- In structural health monitoring, AE is used to detect and assess damage and defects in bridges, buildings, and other infrastructure.

- In the aerospace industry, it’s used to monitor the structural integrity of aircraft components.

- In manufacturing, AE can be used for quality control and process monitoring.

- In the oil and gas industry, it helps detect and monitor pipeline corrosion and integrity.

Advantages

- Non-destructive: AE testing does not damage the material or structure being inspected.

- Real-time monitoring: It provides continuous data, allowing for early detection of defects or structural changes.

- Sensitivity: AE can detect small defects or changes in materials.

- Location identification: AE can pinpoint the source of the acoustic emission event.

Challenges

- Interpretation: Analyzing AE data can be complex, requiring expertise to differentiate between relevant and irrelevant signals.

- Environmental noise: External noise sources can interfere with AE measurements.

- Calibration: Sensors need to be regularly calibrated to ensure accurate results.

Overall, acoustic emission is a valuable technique for assessing the integrity and safety of critical structures and materials, contributing to the prevention of catastrophic failures and ensuring the reliability of various industrial applications.