Vanillin is an organic compound that is commonly used as a flavoring agent. It is a white or slightly yellowish crystalline powder with a sweet, vanilla-like odor and taste. Vanillin is the main component of the natural vanilla bean extract, but it can also be produced synthetically from various sources, such as lignin or guaiacol.

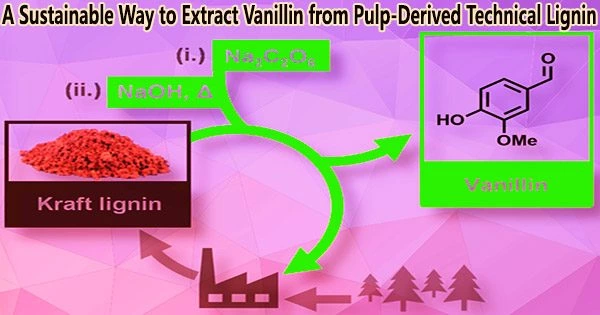

Huge amounts of technical or Kraft lignin are formed during pulp production. Due to its difficulty in processing, this lignin is typically only burned to provide heat. A team of researchers, reporting in the journal Angewandte Chemie, has now succeeded in developing a green method for recovering the flavoring agent vanillin from this raw material.

The only components that need to be added to this process aside from power and heat are recycled materials from the papermaking process.

Wood needs both cellulose and lignin to function. Vanillin, the primary flavoring component from the vanilla plant, shares the molecular structure of lignin, making it possible to make vanillin from lignin, however the procedure is time-consuming.

At the moment, vanillin is produced industrially using lignosulfonate, a compound that is also created during several papermaking processes.

Most people only know of it from vanilla flavoring, but it is present in most chocolates and perfumes as well.

Siegfried Waldvogel

All lignin must be eliminated before using wood fibers to manufacture paper; otherwise, the paper will acquire the lignin’s brown hue. However, the waste product in the most commonly used pulping method for industrial papermaking, the Kraft method, is not lignosulfonate but rather a technical lignin referred to as Kraft lignin.

Kraft lignin cannot currently be used as a raw material because it is significantly more difficult to oxidize and depolymerize than other lignins. Instead, it is simply burnt as fuel for papermaking processes.

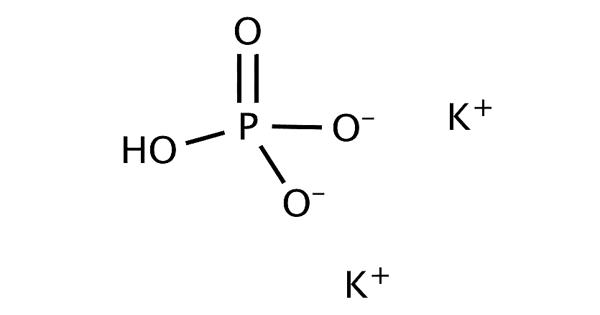

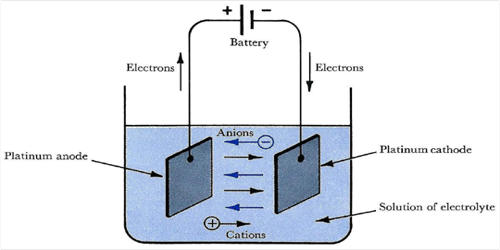

Siegfried Waldvogel and a team of researchers at the University of Mainz, Germany, have now discovered a method for producing vanillin from Kraft lignin. They claim that the process is convenient and environmentally friendly because it employs the same raw materials that are used in the production of pulp and uses no harmful chemicals. The electrolysis of sodium carbonate to produce the oxidizer is a crucial stage in this novel technique.

“The idea started many years ago when playing around with innovative electrode materials that make it possible to take simple carbonates and make an oxidizer from them,” explains Waldvogel.

The researchers noticed that when conducting electrolysis using one of these electrode materials boron-doped diamond the sodium carbonate was quickly converted to peroxodicarbonate. The team then found out that this oxidizer was strong enough to degrade stubborn Kraft lignin.

The team report that, when freshly produced, the peroxodicarbonate depolymerizes and oxidizes Kraft lignin with similar effectiveness to traditional methods. Yet, unlike these traditional techniques, no toxic chemicals are employed or created during the procedure.

The need for vanillin is high: “Most people only know of it from vanilla flavoring, but it is present in most chocolates and perfumes as well,” explains Waldvogel.

Vanillin is also a precursor material for pharmaceuticals. Twenty thousand tons of vanillin are required annually for all these purposes, and the vanilla plant cannot meet this need on its own.

The first steps are being taken, but it hasn’t been possible to use Kraft lignin to fulfill demand up until now. Waldvogel and the team are already working on a pilot plant to test scaling up.