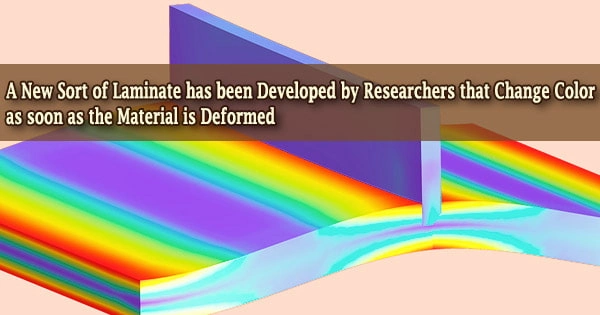

Researchers at ETH Zurich have invented a new type of laminate that changes color when it is deformed. The materials scientists will be able to kill two birds with one stone by creating a lightweight composite material that can inspect itself.

Lightweight construction has made its way into a variety of industries, including automobile, shipbuilding, and aviation production.

In addition to classic lightweight metals like aluminum, magnesium, and titanium, composite materials are increasingly being used in load-bearing applications. This necessitates the development of novel procedures and methods for detecting damage to, and even possible failure of, such as yet unstudied materials.

Researchers from ETH Zurich’s Complex Materials Group have developed a lightweight material that employs color change to detect internal deformation and consequently possible material breakdown at an early stage, in partnership with researchers from the University of Fribourg. Their laminate, which is made up of separate layers, is translucent, break-resistant, and still very light.

We used fluorescent molecules because you can measure the increase in fluorescence very well and you don’t have to rely on subjective perception.

Tommaso Magrini

Artificial mother-of-pearl combined with polymer

The laminate is made up of layers of plastic polymer and artificial nacre or mother-of-pearl that alternate. The latter is a specialty of the Complex Materials Laboratory and is based on the mussel shell as a biological example.

It is made up of thousands of parallel glass platelets that are compressed, sintered, and cemented using polymeric resin. This makes it highly tough and resistant to breakage. The researchers added an indicator molecule synthesized specifically for this application at the University of Fribourg to the second layer, which is a polymer.

When the polymer is stretched, the molecule is activated, which causes the fluorescence to change. The fluorescence becomes increasingly brighter as the material extends and more of these molecules are activated.

Fluorescence indicates overstressed parts

“We used fluorescent molecules because you can measure the increase in fluorescence very well and you don’t have to rely on subjective perception,” says Tommaso Magrini, lead author of the study, which was recently published in the journal ACS Applied Materials and Interfaces.

The system could also have been set up to produce a color change that would be directly perceptible from the outside. But: “The perception of colors is subjective and it is difficult to draw conclusions about changes in the material,” Magrini says.

The researchers can now detect overstressed spots within the composite material using fluorescence, even before fractures emerge. This enables for the early discovery of weak regions in a structure before they fail catastrophically.

One prospective application for the innovative laminate is in load-bearing structures such as those found in buildings, aircraft, or automobiles, where early detection of failure is critical.

However, whether and how the material can be made on a large scale remains to be seen. It only exists as a proof of concept at the moment, on a laboratory scale.