When several solid phases arise from a liquid phase and self-organize to produce a three-dimensional (3D) pattern, this is when metals and ceramics acquire their eutectic structure. Historically, it was thought that only a melt-solidification procedure could produce eutectic structures.

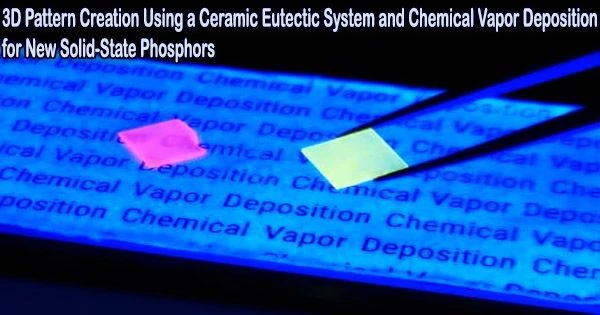

Researchers at Yokohama National University (YNU) have developed a chemical vapor deposition (CVD) process that allows precursor gases to react and generate solid-state composites with ordered structures in a YAG (yttrium alumina garnet)-alumina ceramic eutectic system.

In their investigation, they saw the development of spatially organized rod- and lamellar-shaped YAG crystals on a sapphire wafer in an alumina matrix. On the other hand, they saw the development of ordered alumina crystals with a YAG matrix under Y-rich circumstances.

The 3D patterns were produced as a result of the precursor’s composition and the sapphire seed crystal selection. The CVD method broadened the variety of chemical compositions that might produce such patterns in comparison to the melt-solidification process.

Our experiments demonstrate potential applications of YAG-alumina chemically deposited eutectics as environmental-resistant LED lighting and high-resolution X-ray imaging.

Yuri Mitsuhashi

Additional rare-earth elements may be doped into the chemically deposited eutectics of YAG-alumina to act as luminous centers. For instance, when exposed to blue LEDs, cerium ions release yellow light, creating white light for solid-state lighting. When subjected to X-rays traveling via a semiconductor device, europium ions produce red light for X-ray radiography.

“Our experiments demonstrate potential applications of YAG-alumina chemically deposited eutectics as environmental-resistant LED lighting and high-resolution X-ray imaging,” says Yuri Mitsuhashi, lead author of the study, conducted the experiments while being a graduate student at YNU.

Alumina is frequently used for structural and optical components and has long been acknowledged as a reliable refractory ceramic material. Aluminates have undergone substantial research as functional ceramic materials, including lasers, phosphors, and energy materials, including rare-earth aluminum garnets and perovskites.

“Among the aluminates, rare-earth aluminum garnets and perovskites have attractive properties and fortunately have eutectic systems with alumina,” says Shogen Matsumoto, who built a lab-made X-ray imaging system during his Ph.D. at YNU. He said, “We can synthesize a novel crystal that combines the advantages of alumina and aluminate.”

This discovery shows that 3D pattern formation in ceramic eutectic composites can happen both during the melt-solidification and vapor deposition processes.

“CVD is ready to make ceramic eutectic composites as functional or protective layers over substrate materials,” says Akihiko Ito, an associate professor at YNU and the principal investigator.

“By contrast, the melt-solidification process, which requires pouring a high-temperature melt exceeding 2,000 degrees Celsius to form ceramic composite coatings on substrates, is impractical. Further research will focus on elucidating the mechanism behind chemically deposited eutectics,” said Ito.