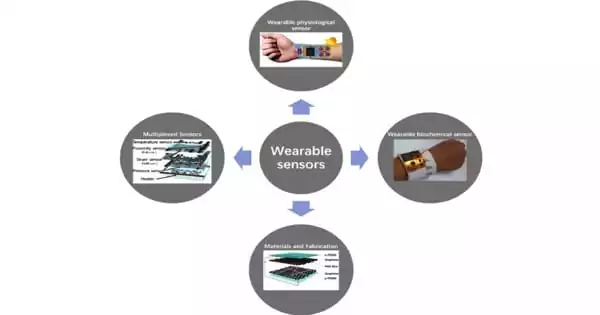

Monitoring vital signs and detecting illnesses can be time-consuming, painful, and inconvenient. However, researchers such as Huanyu “Larry” Cheng, Dorothy Quiggle Career Development Assistant Professor of Engineering Science and Mechanics at Penn State, are aiming to improve health monitoring by developing wearable sensors that collect data for clinicians while minimizing patient pain.

Cheng has designed unique components and methodologies to produce products such as wearable head scanners, needle-free glucose monitors, wearable antennas, and printable electronics since joining the Penn State Department of Engineering Science and Mechanics in 2015. The sensors, which are constructed of flexible electronics, can track patients’ physical movements as well as chemical signals in their perspiration, skin, and other areas to help diagnose or advise treatment plans.

Now Cheng is working to make devices sustainable, resilient, and self-charging.

According to Cheng, industry partners from all disciplines realize the need for innovation in wearable electronics and are eager to invest. Meta Reality Labs, Facebook’s technology development arm, gave Cheng $150,000 in unrestricted funds in December 2021 to enhance biodegradable, stretchable, energy-generating technologies.

“There is a tremendous need for environmentally friendly, self-charging sensors that can monitor patients’ vital signs without adding to their physical or financial stress – and we’re seeing that those solutions can be applied to a wide range of difficulties,” Cheng added. “My research program is focused on understanding the interactions and constraints of diverse materials in order to fabricate novel methods and devices to address these difficulties.”

Our research program is focused on understanding the interactions and constraints of diverse materials in order to fabricate novel methods and devices to address these difficulties. We want to make every component of these systems as cost-effective, durable, and long-lasting as possible.

Huanyu Larry Cheng

Self-powered, rechargeable wearables

Creating versatile, cost-effective sensors is one thing; powering them is another. Although self-charging power units for stretchy energy harvesters already exist, Cheng claims that they are expensive to manufacture, cumbersome to transport, and “suffer from low and unreliable output power.”

Graphene-based materials, on the other hand, are light and small. A single layer of hexagonally organized carbon atoms makes up graphene. Manufacturers can make multilayer graphene foams in a variety of shapes at a reasonable cost by using a laser. When properly formed, graphene can harvest energy from motion, such as human body movements, and store it in micro-supercapacitors as electrical energy.

Cheng and his colleagues used this technique to create a self-powered, stretchy health monitor made of porous graphene foam. The facts were published in Applied Physics Review. The self-powered device, like other types of wearable sensors, can measure users’ vital signs such as pulse, temperature, ECG, blood pressure, and blood oxygen. The sensor does not require a wired power supply or a charger, according to Cheng.

“While monitoring numerous signals, the device collects power from body movements in a sort of closed feedback loop,” Cheng explained, stressing that Bluetooth or wireless data transmission may completely eliminate wired sensors. “It is a fully integrated system built using the same basic, low-cost, scalable manufacturing technologies that we use to create individual monitoring components.”

The method has various potential applications, including tracking the movements of species such as bats and seals, according to Cheng. The device can be recharged indefinitely by the motions of the animals.

“We merged numerous of our prior inventions to create this whole system – but we’re not done,” Cheng explained. “We want to make every component of these systems as cost-effective, durable, and long-lasting as possible.” In this spirit, Cheng and his colleagues have recently published two articles outlining breakthroughs in more efficient, cost-effective, and renewable approaches to improving sensors and their applications.

From tissue paper to pressure readings

Tissue paper decorates presents, protects breakables, and, thanks to Cheng and his team, monitors blood pressure and respiratory conditions. In December, Cheng published a paper in ACS Applied Materials & Interfaces on a wearable sensor that detects blood pressure and movement using a small skin patch built from inexpensive, widely available tissue paper.

The device is made by dipping a piece of tissue paper into conductive material, then pressurizing it to form a 3D scaffold and encapsulating it to become a sensor that attaches to the skin. The wireless device attaches to the user’s forearm and measures blood pressure by monitoring the dilatation and constriction of a blood artery in the wrist. According to Cheng, it is a considerably smaller and easier-to-use device than a traditional blood pressure monitor, which employs a cuff to apply pressure to an arm to obtain a single reading.

“A blood pressure cuff at the hospital wakes up patients who are trying to sleep,” Cheng explained. “This technology would allow for continuous, remote monitoring around the clock.” The device collects data on blood pressure, heart rate, and cardiac activity, which may then be transmitted to a health care professional via a Bluetooth smartphone app.

The gadget also measures pulsation and motion of the body through pressure readings, allowing specific movements, such as joint range of motion, to be quantified. Cheng stated that the data might also be used to track healthy movement, such as hand motions during the speech, in order to inform robotic implants that contain artificial intelligence.

“The pressure-based production approach is simple and inexpensive,” Cheng explained. “All of the materials, such as the silver in the sensors, may be recycled after the device is decommissioned, and they are easily accessible.”

The sensor is light enough to be comfortable while yet being strong enough to withstand jogging or sweating. The sensor was also integrated into a face mask, allowing the researchers to remotely monitor respiratory variables, including potential irregularities, enabling early identification of emergencies such as opioid overdose.

Cheng added that in the future, he will look into implementing medicine delivery through the device when it recognizes specific symptoms. “A future version of the device may detect a drug overdose in real-time and inject naloxone, potentially saving a user’s life,” Cheng explained.

A sensor for humid environments

Most wearable sensors repel water with superhydrophobic polymers, but they have limited flexibility and frequently degrade quickly in humid situations, which is a serious concern in field hospitals or other medical facilities without temperature control, according to Cheng.

Cheng’s lab solved the challenge by combining superhydrophobic materials with Joule heating, which involves passing an electric current through a conductor to generate heat. Even when the sensor is in an environment with 99 percent humidity, the heat ensures continual moisture resistance. As a result, a new flexible pressure sensor that can survive high levels of humidity has been developed. The information was made public online ahead of the March issue of Chemical Engineering Journal.

Cheng’s sensor is comprised of a transitional metal and sodium alginate, a food-grade substance produced from algae, which allows the gadget to reject huge water droplets in the same way as a lotus plant does in nature. “Water droplets on lotus leaves to roll off smoothly, ensuring that water does not accumulate,” Cheng explained.

The sensor, which uses robust materials and steady heat, can monitor a user’s vital signs even in “severe use scenarios,” such as when users are sweating while jogging, biking, or sunbathing, according to Cheng. Despite his numerous discoveries and improvements, Cheng is far from done; his research team will continue to alter the wearable medical device realm.

“We don’t know where inspiration will strike — tissue paper, lotus plants, motion power, and other sources have all shown to be fruitful,” Cheng remarked. “Our team is relishing the challenge of developing the next generation of medical devices, from discovery to research to implementation.”