Sound-diffracting walls and rubberised asphalt ingredients tackle the major environmental concern of noise pollution from traffic. In cities across the European Union, noise is a significant health hazard along with air pollution. Efforts are underway to reduce a major source of both: traffic.

Noise is the number-two environmental source of health troubles, after air pollution, according to the United Nations World Health Organization. In the European Union, 22 million people suffer chronically high annoyance from environmental noise. And 12 000 premature deaths occur every year in the EU as a result of long-term exposure to environmental noise, of which traffic is among the main sources.

But, as with climate change, the EU fight against noise pollution involves not just mitigation but also adaptation. While traffic can be scaled back through improved urban design, motor-powered transport will continue to emit noise and a key challenge is finding ways to limit the impact on people.

That’s where Bart Willems has a role to play. He is enthusiastic about a type of wall that he says can unite people more than divide them.

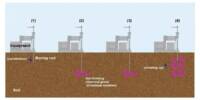

Willems was involved in a research project to reduce irksome noise from roads and railways by using barriers that bend sound waves and direct them away from homes. The phenomenon is known as diffraction.

Infrastructure doesn’t move quickly, especially when laws have to change before we can introduce our technology. Nevertheless, we’re optimistic that, in the coming three years, people in Europe should start regularly seeing our barriers.

Bart Willems

Nerve-racking

The goal was to tackle a serious yet under-appreciated environmental problem by thinking about it differently. The two conventional methods are, building concrete walls to block noise and using materials for roads and railways that absorb it better.

‘Diffraction offers a third solution,’ said Willems, whose Dutch company 4Silence BV coordinated the Horizon-funded WHISSPER project.

Netherlands-based 4Silence has developed walls that have grooves of varying depths, which reduce horizontal noise by bending it upwards in the vertical direction. This means smaller barriers can be used to deflect more noise away from surrounding people. ‘If one of our walls is one metre high, it will reduce noise by seven to nine decibels,’ Willems said. ‘A regular screen would need to measure three metres to accomplish the same effect.’

The WHISSPER project tested the technology with the idea of fighting traffic noise through diffraction beginning in 2019 and ending earlier this year. With its sound-redirecting walls having undergone trials in the Netherlands, Belgium, Germany and Denmark, the company says the barriers are easy to install and maintain. It is now seeking to go to market.

‘We have since started our first commercial projects in the Netherlands,’ Willems said. ‘And we’re looking to further commercialise our walls in different countries.’

For these initiatives, 4Silence generally works with local governments such as the municipality of Eindhoven or the province of Utrecht. In Germany and the UK, commercial projects have also been started for the Augsburg State Building Authority and Transport for London. In the coming months, new buyers across Europe are set to be announced, with 4Silence also eyeing customers in countries including Belgium and Denmark.

Budget relief

Noise diffracting barriers also benefit government budgets because they are half as expensive as traditional noise-reduction measures.

Public purses for infrastructure are already stretched. Spending in Europe to counter road and rail noise amounts to about €5.4 billion per year, or 6% of total annual expenditure on both forms of transport. Yet people’s exposure to traffic noise in the EU is increasing. More than one in four Europeans faces levels dangerous to health in homes, schools and workplaces.

Meanwhile, on the mitigation front, improvements are being sought in the traditional methods for tackling traffic noise. A separate Horizon-funded project called SILENT RUBBER PAVE is making asphalt spongier and hopefully quieter in an ecologically friendly way. The project involved a Spain-based company called Cirtec.

Good vibrations

Cirtec is poised to sell a new asphalt additive called RARx, which is made with rubber from end-of-life tyres. RARx is added to asphalt as a way of absorbing some road-traffic noise.

While putting rubber powder in asphalt has been tried before, practical challenges arose. ‘Before contractors added the rubber mix directly into the asphalt, which caused a lot of problems,’ said Guillermo Rodríguez Marfil of Cirtec. ‘It caused problems with the mix—and cleaning up the equipment afterwards was hard.’

With RARx, the rubber powder is blended with mineral additives like bitumen in the factory, making it easier for asphalt producers to use. Car noise is reduced by 4-5 decibels, according to Rodríguez Marfil. ‘The mix reduces the stiffness of the asphalt, which causes a lower vibration in the tyre, and in turn less noise,’ he said.

It can also extend the life cycle of current roads, leading to lower maintenance costs. Furthermore, the entire concept is circular given that the rubber mix is made from used tyres. RARx is being rolled out in countries including Spain. Tests and construction projects were also conducted in Germany, Italy, Portugal and Ireland, partly under the SILENT RUBBER PAVE umbrella.

Produced in Spain, RARx will also be manufactured in the second factory under construction in Mexico—Cirtec’s biggest market, according to Rodríguez Marfil. ‘The future looks bright,’ he said. ‘We are working on several continents and our impact is growing. We’re saving public administrations money and reducing noise for citizens.’

Regulatory roadblocks

Beyond finding markets for their new noise-reduction tools, both Cirtec and 4Silence are counting on regulatory changes to facilitate business growth. Because roads are often constructed by governments and their subcontractors, the activity is highly regulated. ‘In the paving industry, they have been doing the same thing for ages, which can be difficult to overcome,’ Rodríguez Marfil said. Willems of 4Silence echoed the point.

‘Infrastructure doesn’t move quickly, especially when laws have to change before we can introduce our technology,’ he said. ‘Nevertheless, we’re optimistic that, in the coming three years, people in Europe should start regularly seeing our barriers.’