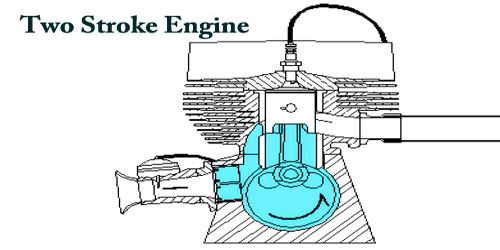

A two-stroke (or two-cycle) engine could be a form of a combustion engine that completes an influence cycle with two strokes of the piston during only one crankshaft revolution. This can be in contrast to an internal-combustion engine that needs four strokes of the piston to finish an influence cycle during two crankshaft revolutions.

Two-stroke engines often have a high power-to-weight ratio, power being available in a narrow range of rotational speeds called the “power band”. Compared to four-stroke engines, two-stroke engines have a greatly reduced number of moving parts.

In the original two-stroke engine (as developed in 1878), the compression and power stroke of the four-stroke cycle is administered without the inlet and exhaust strokes, thus requiring just one revolution of the crankshaft to finish the cycle. The fresh fuel mixture is forced into the cylinder through circumferential ports by a rotary blower within the two-stroke-cycle engine of a so-called uniflow type.

Actually, the first commercial two-stroke engine involving in-cylinder compression is attributed to Scottish engineer Dugald Clerk, who patented his design in 1881. However, unlike later two-stroke engines, he had a separate charging cylinder. The crankcase-scavenged engine, employing the area below the piston as a charging pump, is usually credited to Englishman Joseph Day. On 31st December 1879, German inventor Karl Benz produced a two-stroke gas engine, for which he received a patent in 1880 in Germany. The first truly practical two-stroke engine is attributed to Yorkshireman Alfred Angas Scott, who started producing twin-cylinder water-cooled motorcycles in 1908.

Construction of a Two-Stroke Engine:

- Piston – Piston transfers the expanding force of gases to the mechanical rotation of the crankshaft through a connecting rod.

- Crankshaft – It converts the reciprocating motion to rotational motion.

- Connecting Rod – It transfers motion from a piston to crankshaft and acts as a lever arm.

- Flywheel – It is a mechanical device that is used to store energy.

- Spark Plug – It delivers electric current to the combustion chamber and in turn ignites the air-fuel mixture leading to abrupt expansion of gases.

- Counters Weight – Counterweight on the crankshaft is used to reduce the vibrations due to imbalances in the rotating assembly.

- Inlet and Outlet Ports – These ports allow fresh air with fuel to enter and exit from the cylinder.

Gasoline (spark ignition) versions are particularly useful in lightweight or portable applications like chainsaws and motorcycles. However, when weight and size aren’t a problem, the cycle’s potential for prime thermodynamic efficiency makes it ideal for diesel compression ignition engines operating in large, weight-insensitive applications, like marine propulsion, railway locomotives, and electricity generation. In an exceedingly two-stroke engine, the exhaust gases transfer less heat to the cooling system than a four-stroke, which suggests more energy to drive the piston, and if present, a turbocharger.

A disadvantage is that the return flow of the gases causes a small loss of fresh charge through the exhaust ports. Due to this loss, carburetor engines operating on the two-stroke cycle lack the fuel economy of four-stroke engines. The loss will be avoided by equipping them with fuel-injection systems rather than carburetors and injecting the fuel directly into the cylinders after scavenging. Such a meeting is attractive as a way of achieving high power output from a comparatively small engine, and the development of the turbocharger for this application holds the promise of further improvement.

Two-stroke petrol engines are preferred when mechanical simplicity, lightweight, and high power-to-weight ratio are design priorities. With the normal lubrication technique of blending oil into the fuel, they even have the advantage of working in any orientation, because the oil reservoir isn’t addicted to gravity; this is often a vital property for hand-held power tools like chainsaws.

Two-stroke engines are found in small scales propulsion applications like motorcycles, Mopeds, and dirt bikes. They’re also common in power tools used outdoors, like lawnmowers, chainsaws, and weed-wackers.

Information Sources: